Protective suit for use in a cooling chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

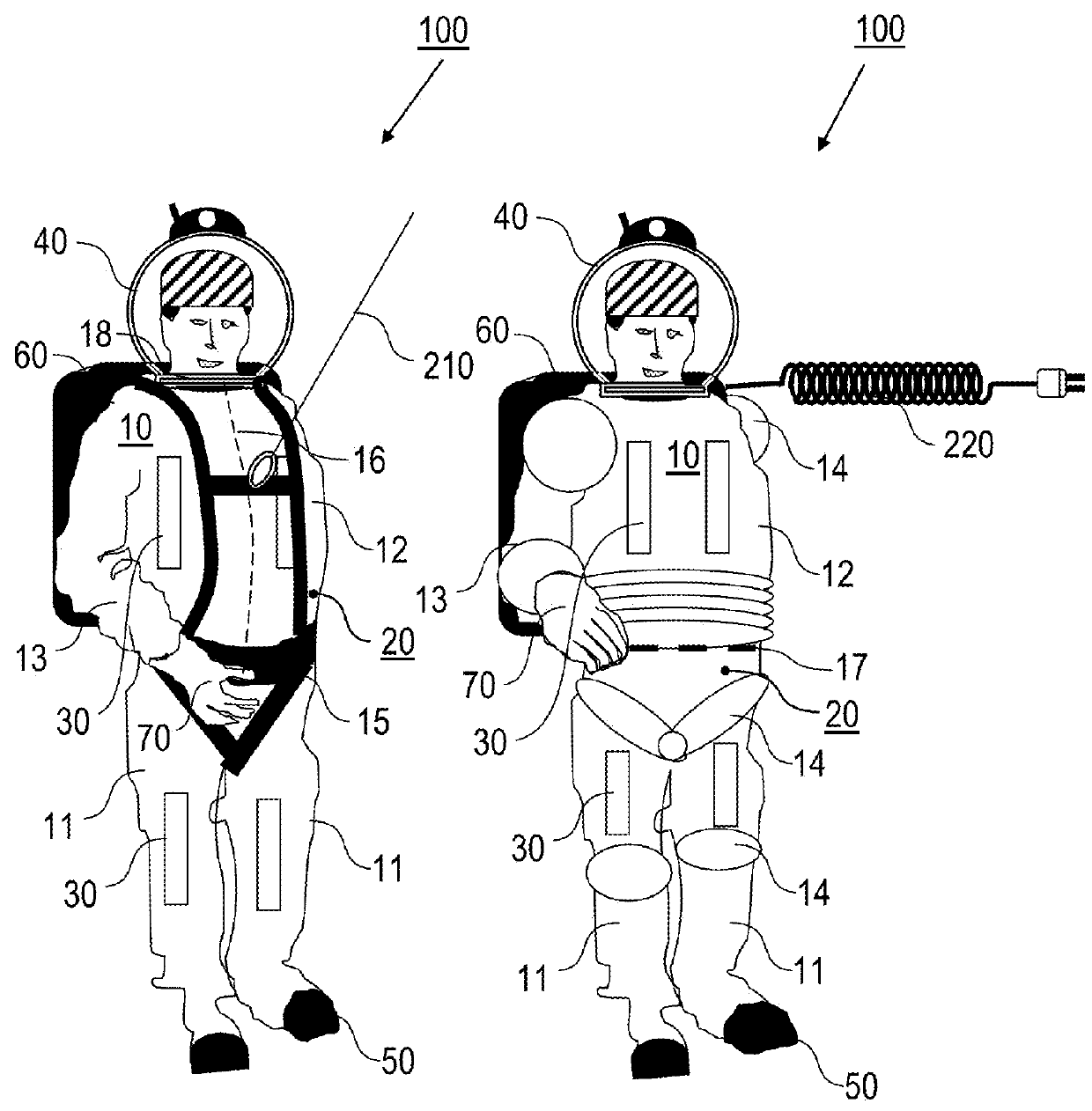

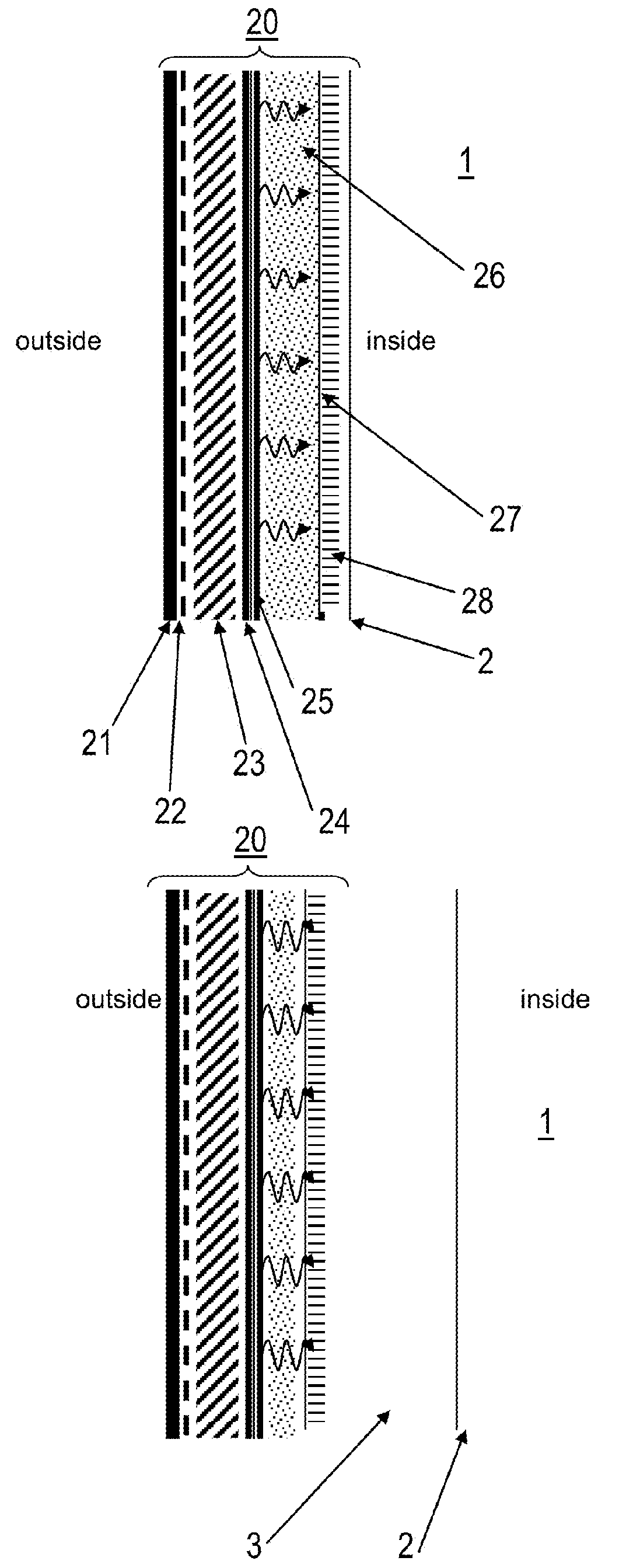

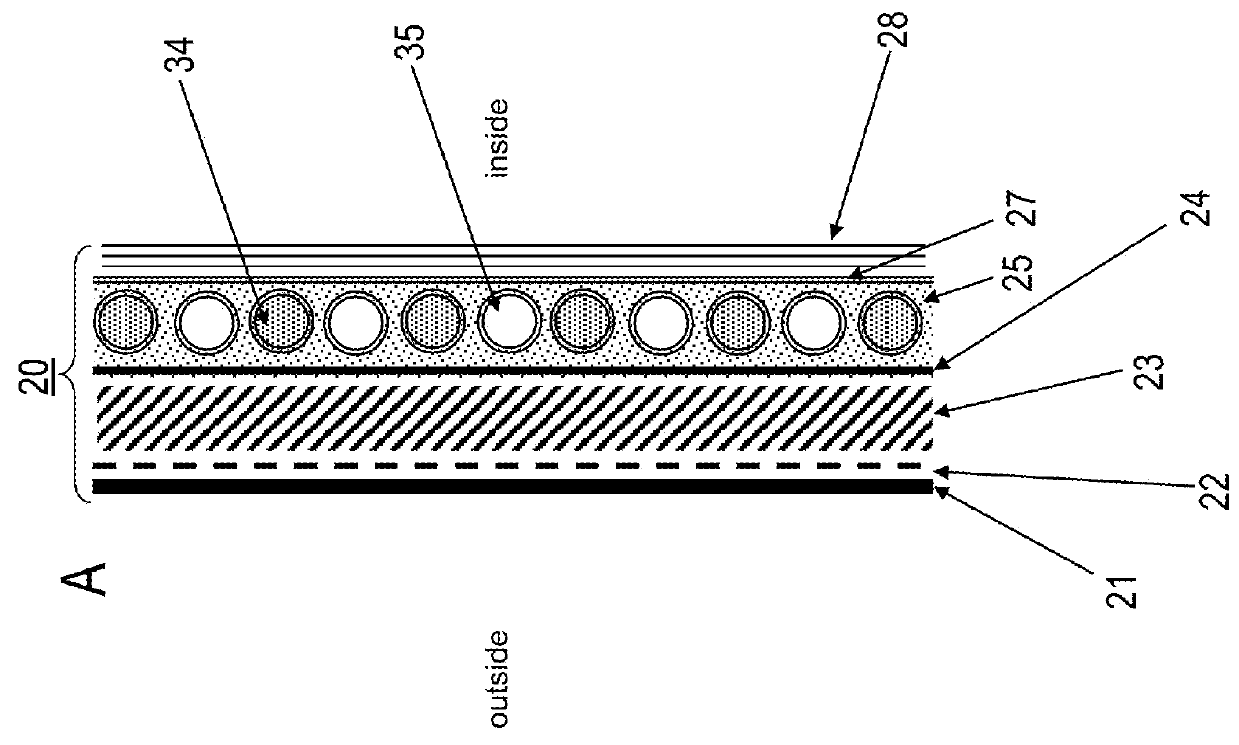

[0008]According to the invention, the above-mentioned objective is achieved by the general technical teaching to provide a protective suit, in particular for an operator in a cooling chamber with a temperature below −100° C., in particular below −150° C., e.g. −190° C. or less, which comprises a body suit for accommodating the operator and a heating device for heating the body suit. The protective suit is adapted for use in a cooling chamber, which is in particular cooled with liquid nitrogen or vapor of the liquid nitrogen. According to the invention, the body suit is made of a thermally insulating sheath material (envelope material). The sheath material forms a gas-tight sheath for the operator. The heating device is connected with the body suit and adapted to the thermal conductivity of the sheath material in such a manner that a physiologically acceptable temperature (temperature above −30° C., in particular above −10° C., e.g. 0° C. or more) is provided inside the body suit. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com