Self-adjusting wedge bumper

a wedge bumper and self-adjusting technology, applied in the direction of mechanical equipment, weapons, transportation and packaging, etc., can solve the problems of extreme environmental changes missile and container rattling and shaking, etc., to minimize the rattle space, minimize the friction force, and reduce the effect of assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The following detailed description illustrates the invention by way of example, not by way of limitation of the scope, equivalents or principles of the invention. The nature, objectives and advantages of the invention will become more apparent to those skilled in the art after considering the following detailed description in connection with the accompanying drawings.

Self-Adjusting Wedge Bumper

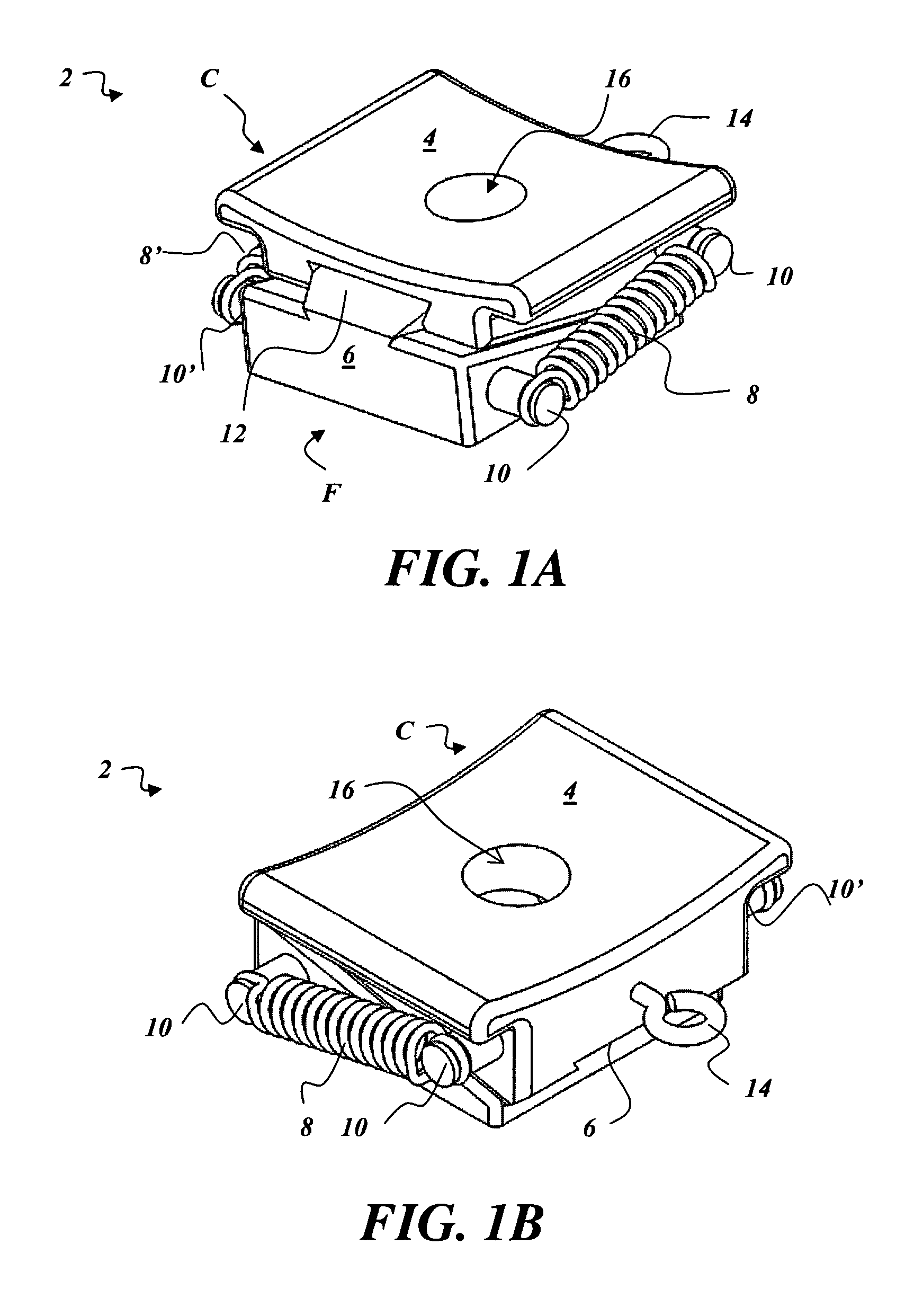

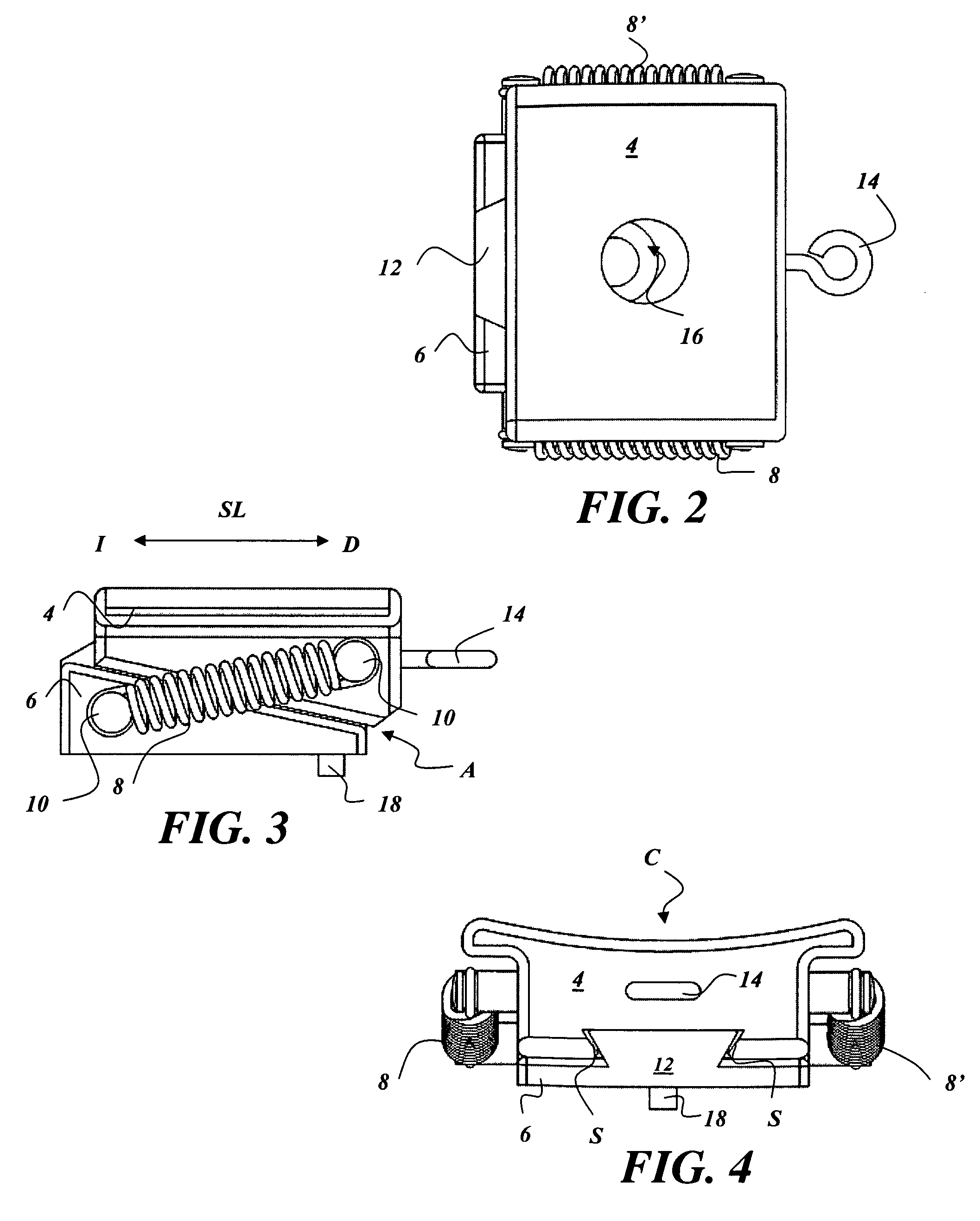

[0032]FIGS. 1A and 1B show perspective views of the wedge bumper 2 comprising a generally rectangular-shaped tapered upper wedge 4 overlapping a generally rectangular-shaped tapered lower wedge 6. The lower wedge 6 has a primary, dovetail-shaped guide rail 12 coupled thereto. Opposing springs 8, 8′ are mounted to opposing machine hook pins 10, 10′ coupled to the sides of the upper and lower wedges 4, 6. As shown in reference to FIGS. 5 and 6, the preferred embodiment comprises secondary internal guide pin rails 24, 24′ extending from the top face of the lower wedge 6 and corresponding gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com