Fluorine gas generator

a generator and fluorine gas technology, applied in the field of onsite type fluorine gas generators, can solve the problems of difficult to obtain highly pure fluorine gas, exceed the supply, and certain amounts of gas should be in stock, so as to prevent the effect of choking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

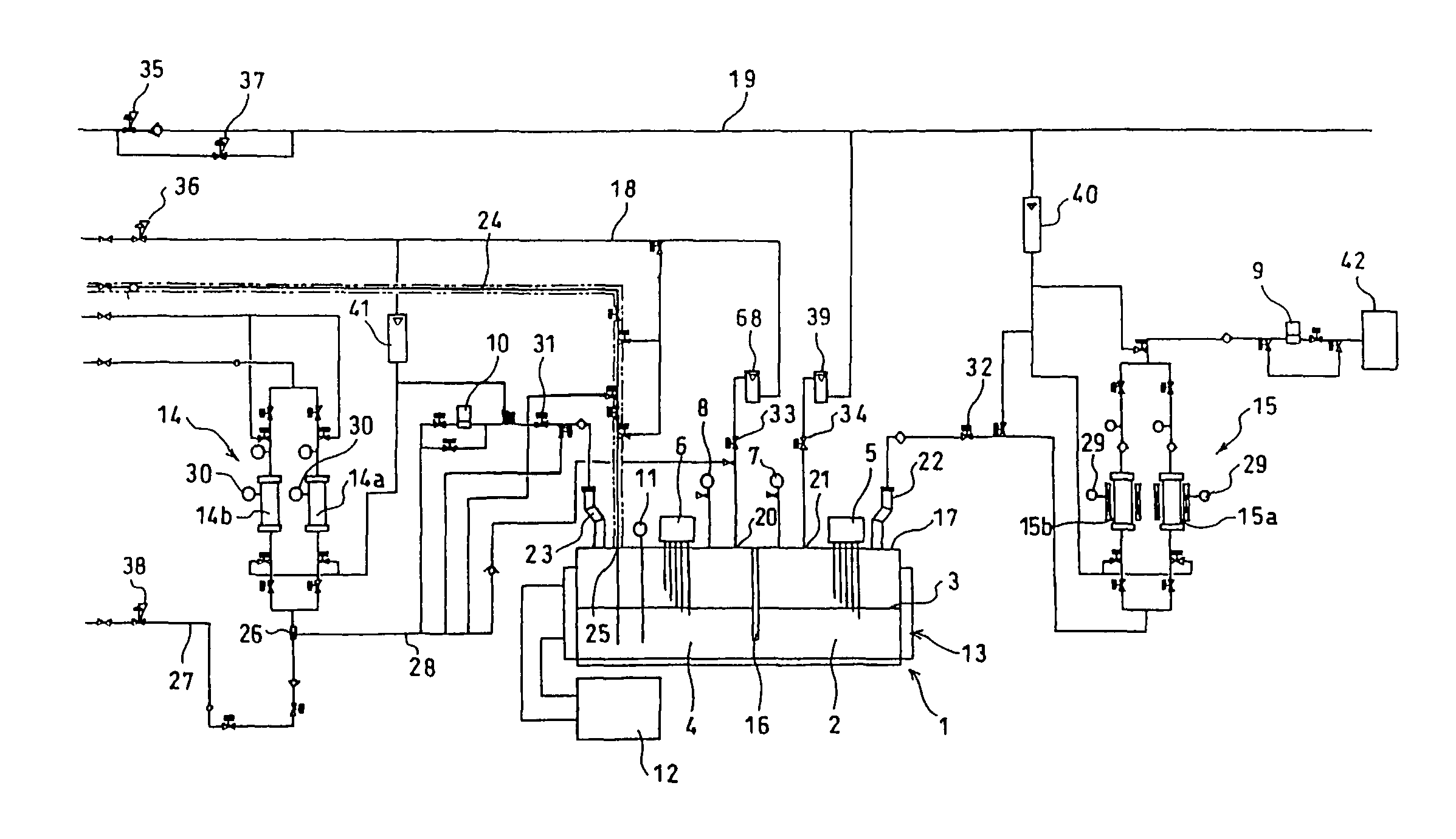

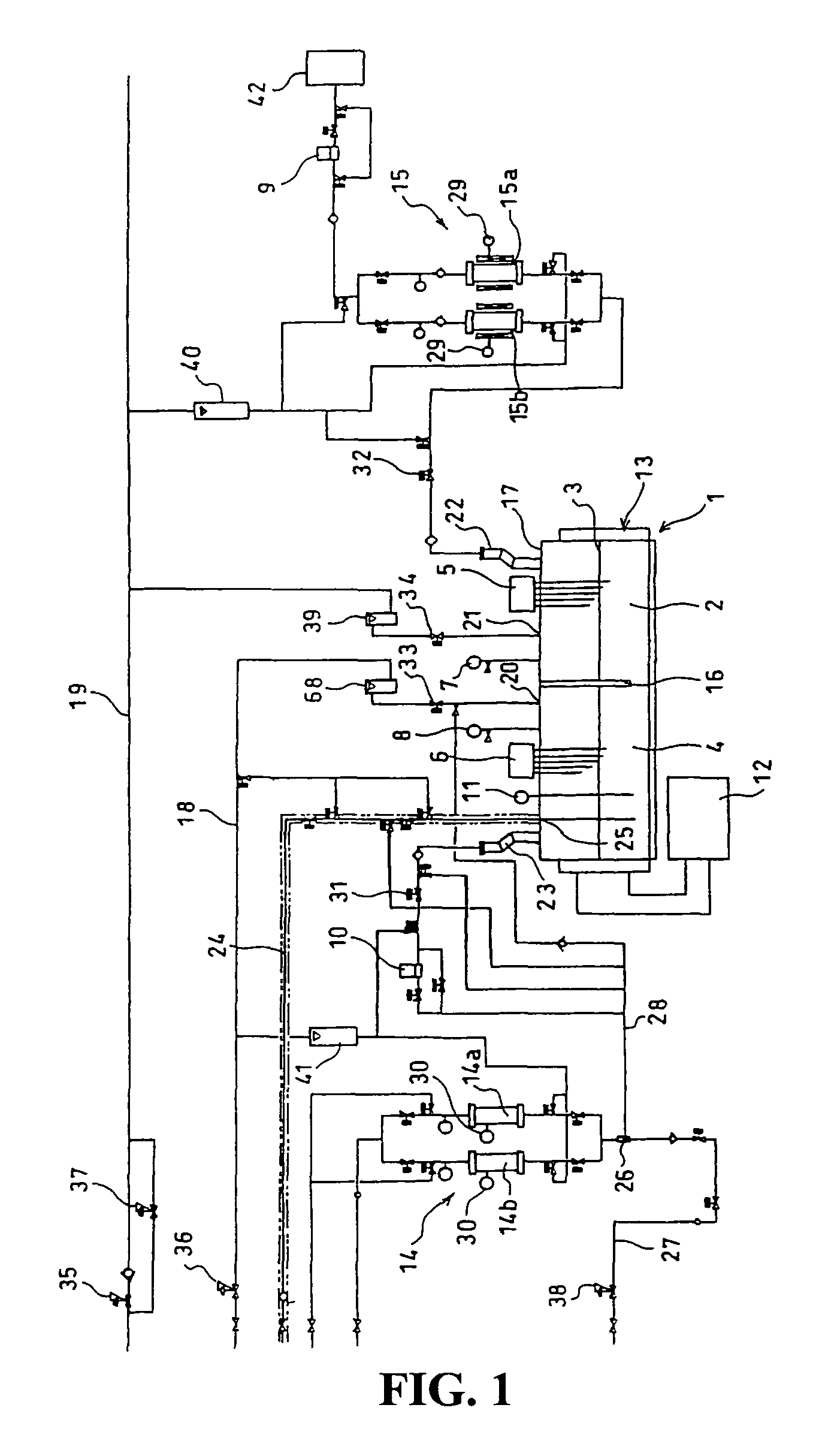

[0027]Now, referring to the drawings, an example of the fluorine gas generator according to the invention is described.

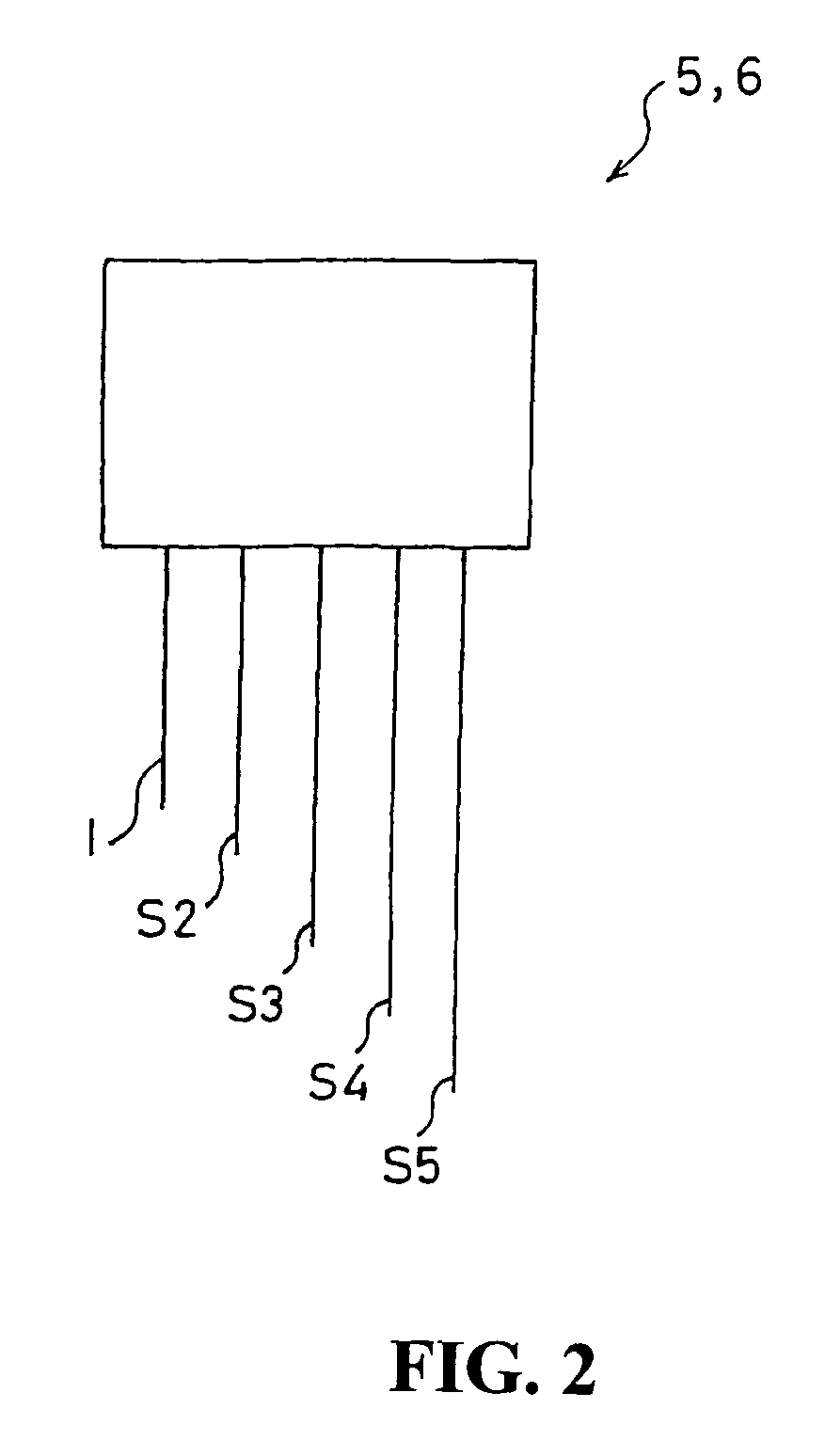

[0028]FIG. 1 is a schematic representation of the principal part of a fluorine gas generator according to the invention. In FIG. 1, 1 is an electrolytic cell, 2 is an electrolytic bath consisting of a fused or molten KF-HF system-based salt, 3 is an anode chamber, 4 is a cathode chamber, 5 is first level sensing means for sensing the level of the electrolytic bath 2 in the anode chamber 3, 6 is second level sensing means for sensing the liquid level in the cathode chamber 4 at 5 level stages. Further, 7 is a pressure gauge for measuring the pressure in the anode chamber, and 8 is a pressure gauge for measuring the pressure in the cathode chamber 4. 9 and 10 are automatic valves operated in association with the pressures measured by the pressure gauges 7 and 8. 11 is a thermometer for measuring the temperature of the electrolytic bath 2, and 12 is temperature control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com