Electrodipping device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]While this invention is susceptible of embodiment in many different forms, there is shown in the drawings and will herein be described in detail one or more embodiments with the understanding that the present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the invention to the embodiments illustrated.

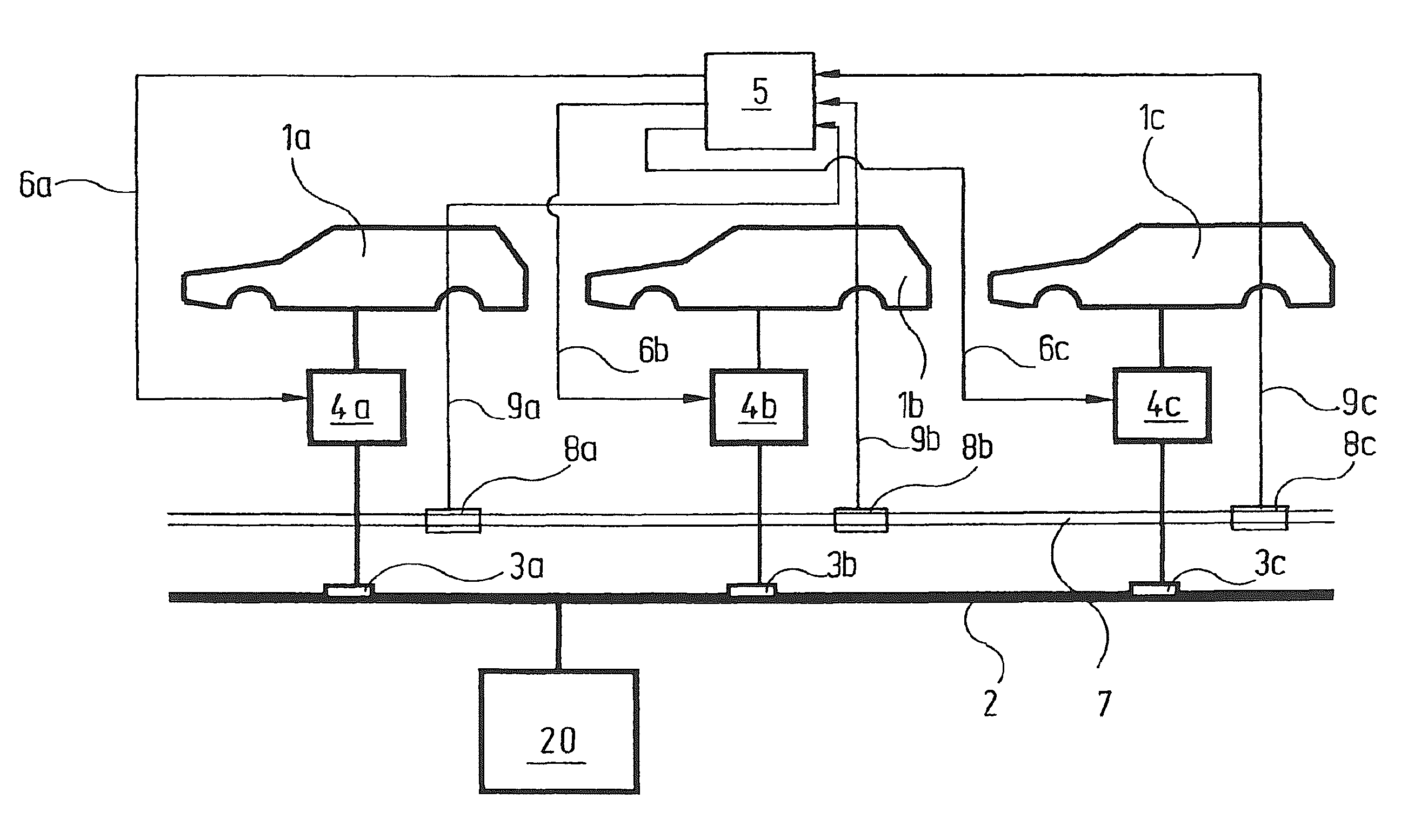

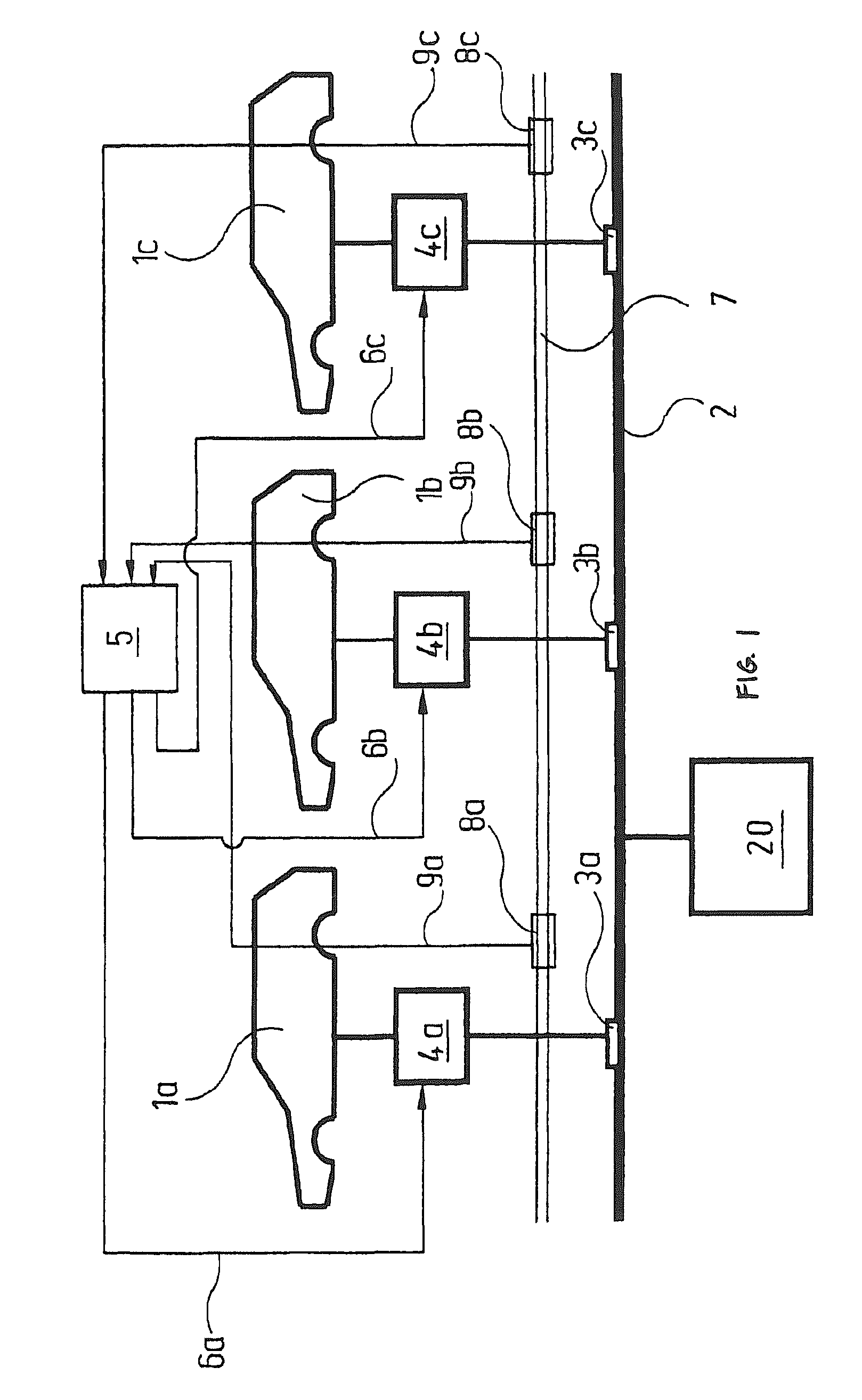

[0030]An embodiment of the invention is explained in greater detail below with reference to the drawing; the single FIGURE shows schematically the voltage supply of vehicle bodies in an electro-dip lacquering bath.

[0031]The drawing shows three vehicle bodies 1a, 1b, 1c in all, which can be thought of as dipped into a lacquer pool filled with lacquering liquid, as described in DE 199 42 556 C2 already mentioned above. The lacquer pool is not shown in FIG. 1, nor is the conveying device with which the various vehicle bodies 1a, 1b, 1c are moved continuously or intermittently through the lacquer pool. A suspension c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric potential / voltage | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap