Grain reaper

a technology for grains and threshers, applied in the direction of threshers, lighting and heating apparatus, drying solid materials, etc., can solve the problems of not configuring ideal equipment, high manufacturing cost, and limited machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

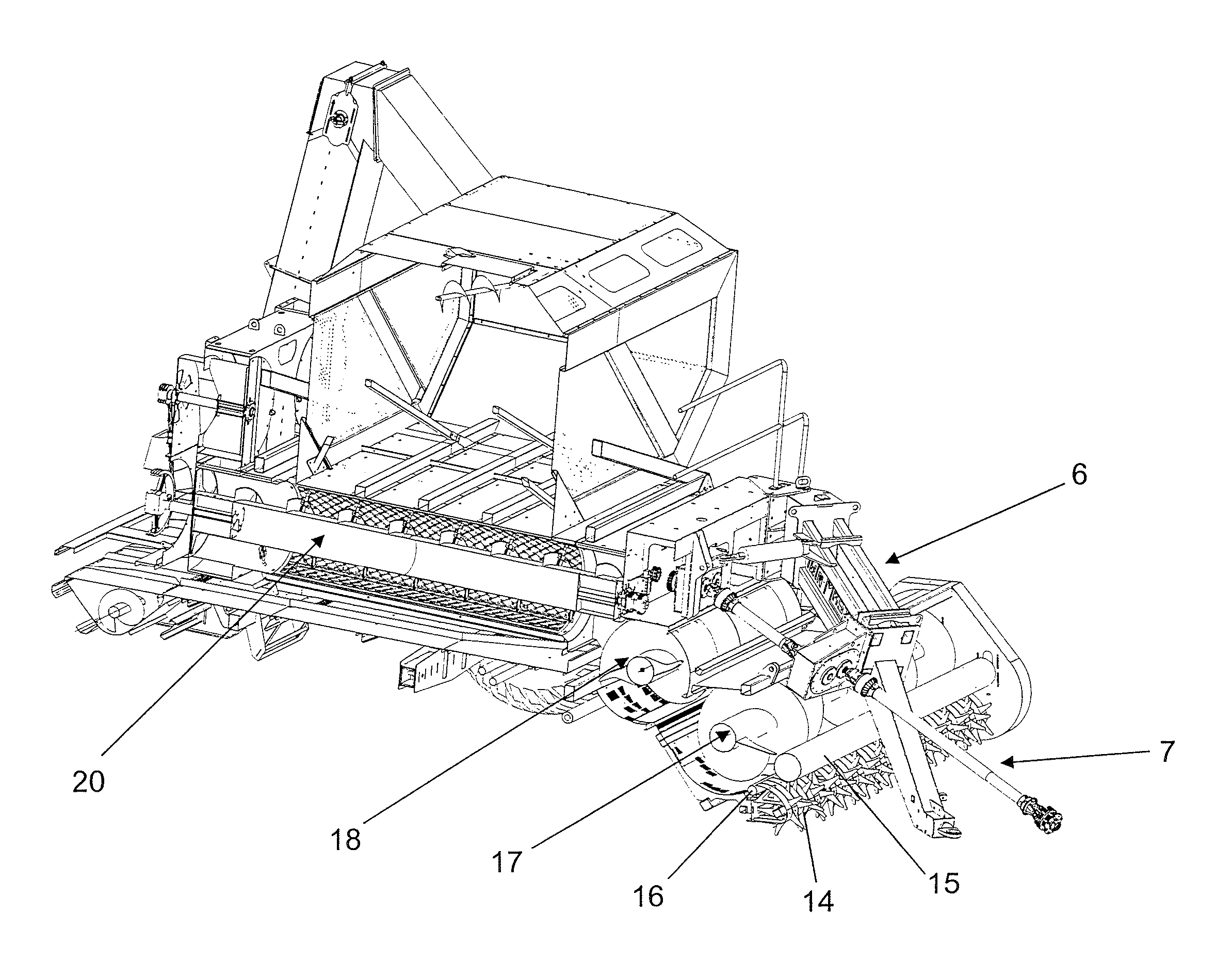

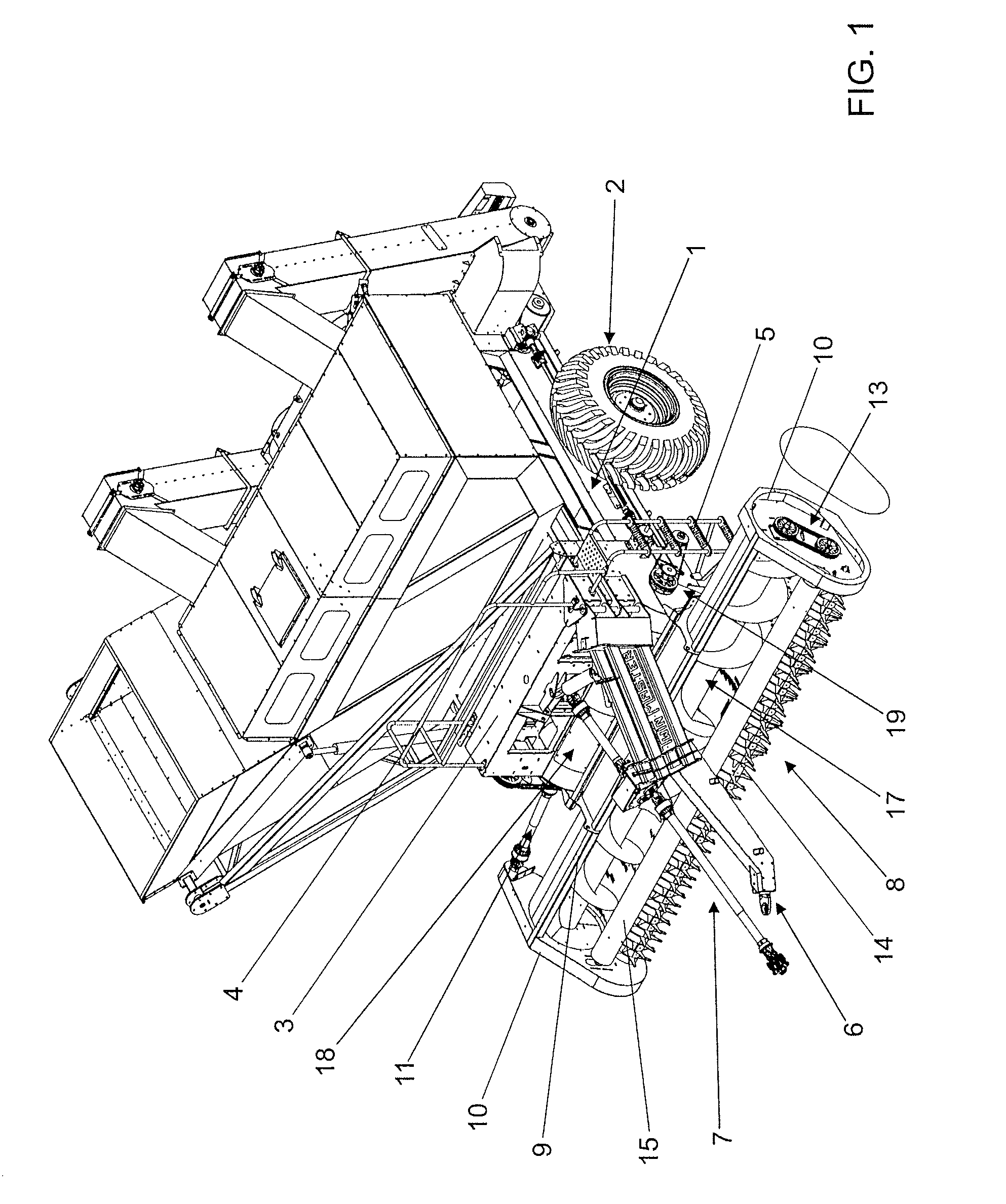

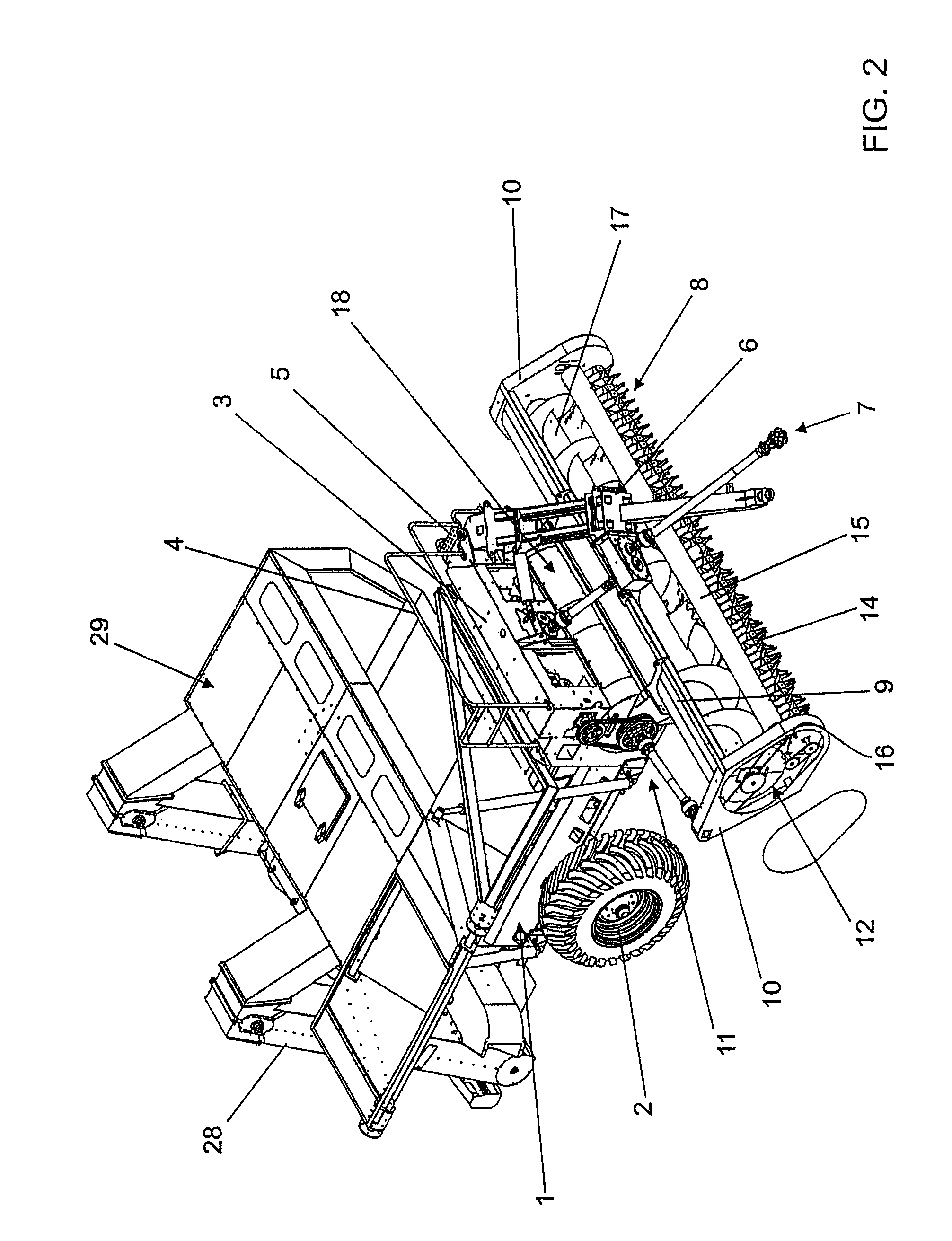

[0034]In FIGS. 1-3, the present invention is featured by initially comprising a box-shaped structural part (1) which is ordinarily with a parallelepiped form, in which all sets are aggregated, starting from its lower part, wherein the wheeling set (2) is mounted and, in the anterior part, a top passageway (3) is provided with a handrail (4) and side stair (5), as well as the set of the coupling shaft (6) with the tractor (not depicted) is mounted on the anterior part of said structure (1) and the first set of cardan takeoff (7) is aggregated inside of it, which stands under said sets and is mounted in the transversal direction regarding the structure (1), the double gathering set (8), which, in turn, has a supplementary structure (9) with box-shaped side portions (10), wherein other takeoff sets (11-12-13) are mounted in synchronization with the first takeoff (7) and, furthermore, the edges of three internal rotating sets are born among said boxes (10), one of which is lower positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com