Modular wheel assembly for a carriage in a mobile storage system

a module wheel and storage system technology, applied in the direction of locomotives, locomotive transmissions, railways, etc., can solve the problems of excessive stress and premature failure of bearings, carriage wheel assemblies, bearing connections, etc., to reduce labor and assembly labor, improve the carriage life and load-carrying ability, and reduce labor. the effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

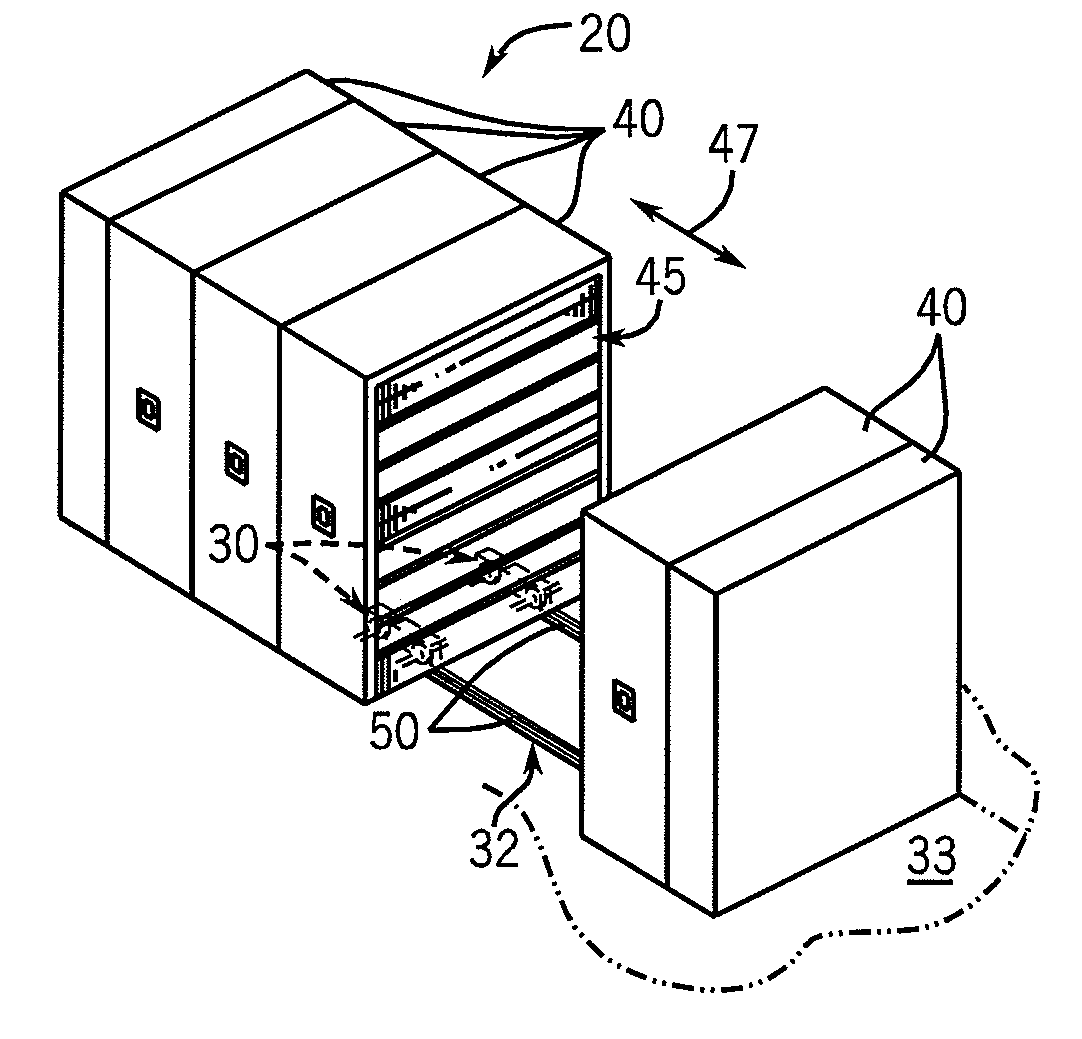

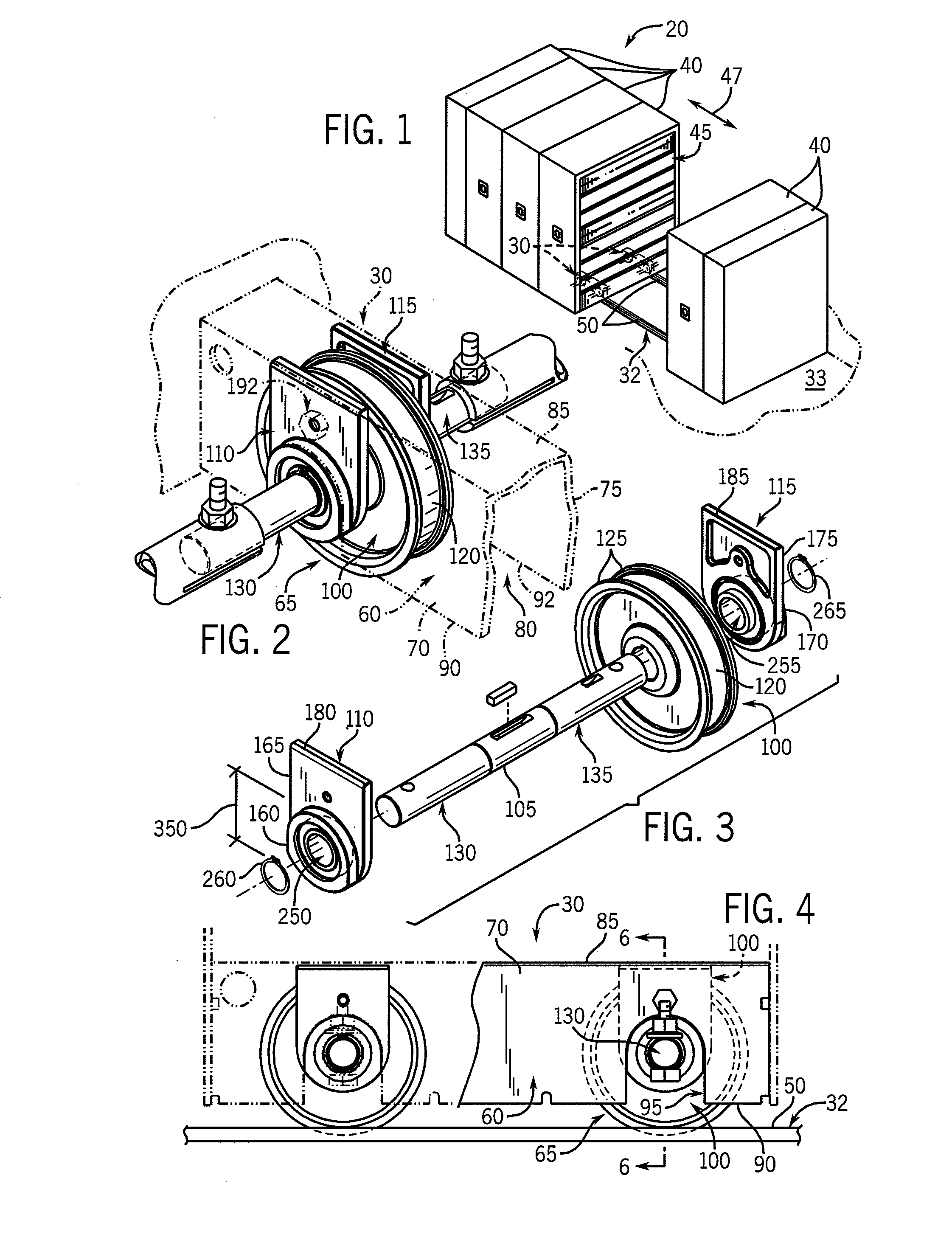

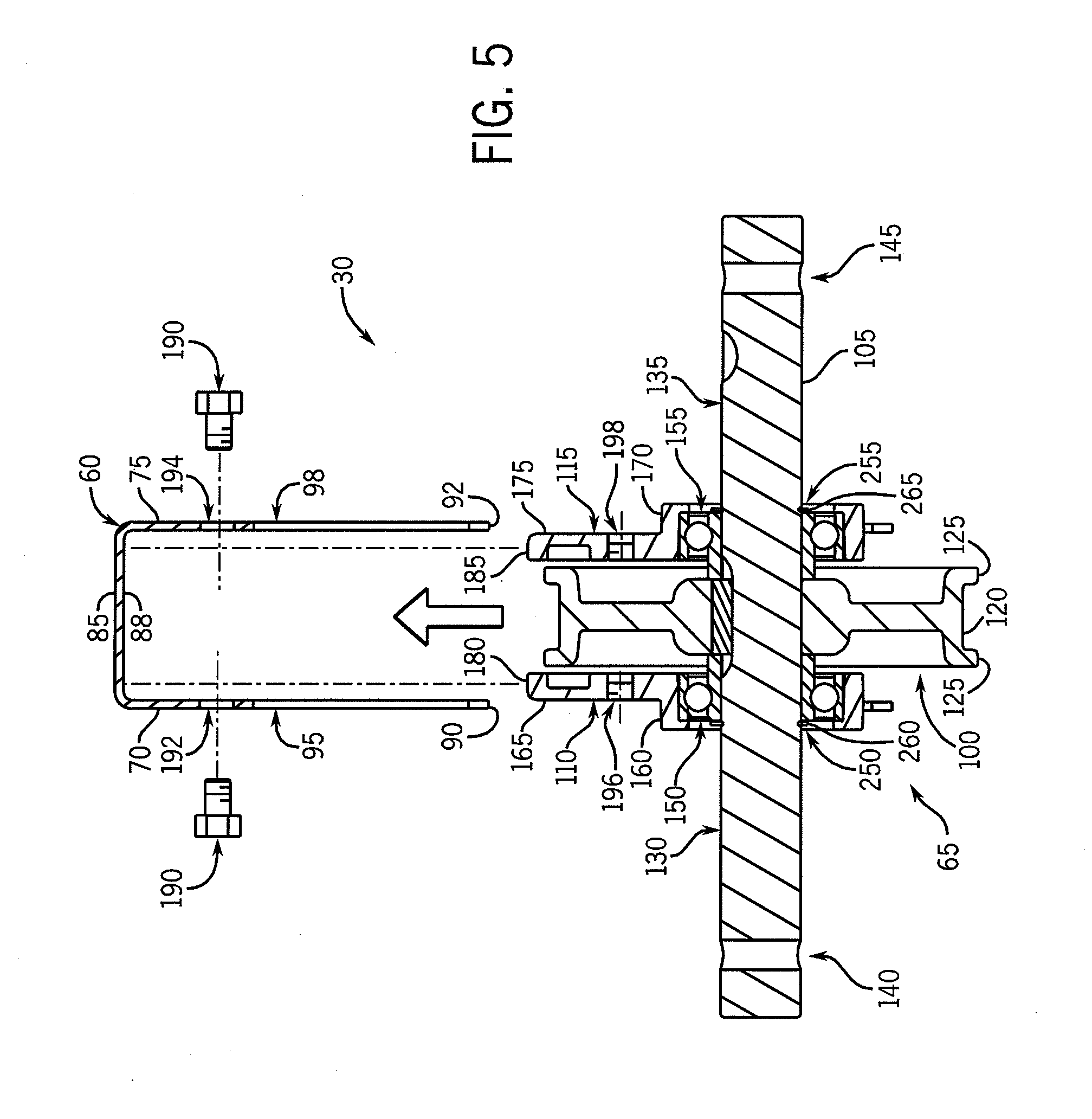

[0022]FIG. 1 illustrates a mobile storage system 20 constructed in accordance with the present invention. Mobile storage system 20 generally includes one or more carriages 30 supported on a rail system 32 that rests on a floor 33 or other supporting surface. Each carriage 30 is adapted to support one or more storage units 40. The storage units 40 are of conventional construction and generally include spaced apart sidewalls, a top wall, a bottom wall and a back wall, in a manner as is known. The illustrated storage units 40 include an open front within which a series of shelves 45 are mounted, again in a manner as is known. It should be understood that, while storage units 40 are illustrated as shelving units, carriages 30 may be use to mount any other type of storage units such as file cabinets, disc or data storage cabinets, bookcases, etc. The mobile storage system 20 may be constructed as original equipment, or may be assembled in a retrofit manner using storage units already in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com