Field emission display device and method of manufacturing same

a display device and field emission technology, applied in the manufacture of electrode systems, discharge tubes with screens, discharge tubes luminescnet screens, etc., can solve the problems of increased manufacturing costs, impaired light emission uniformity of phosphor surfaces (display surfaces) of field emission display devices, and increased manufacturing costs, so as to achieve high assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

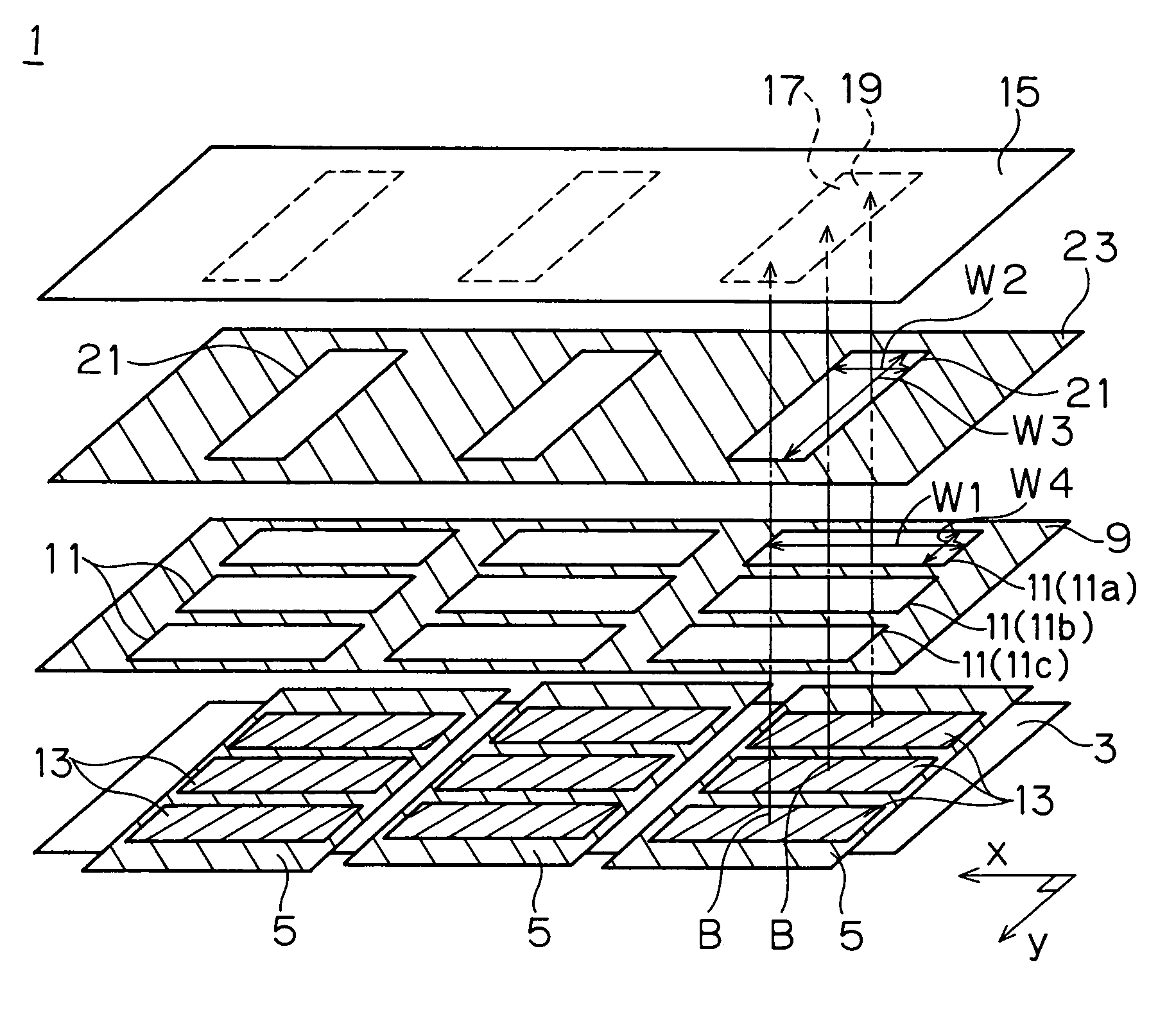

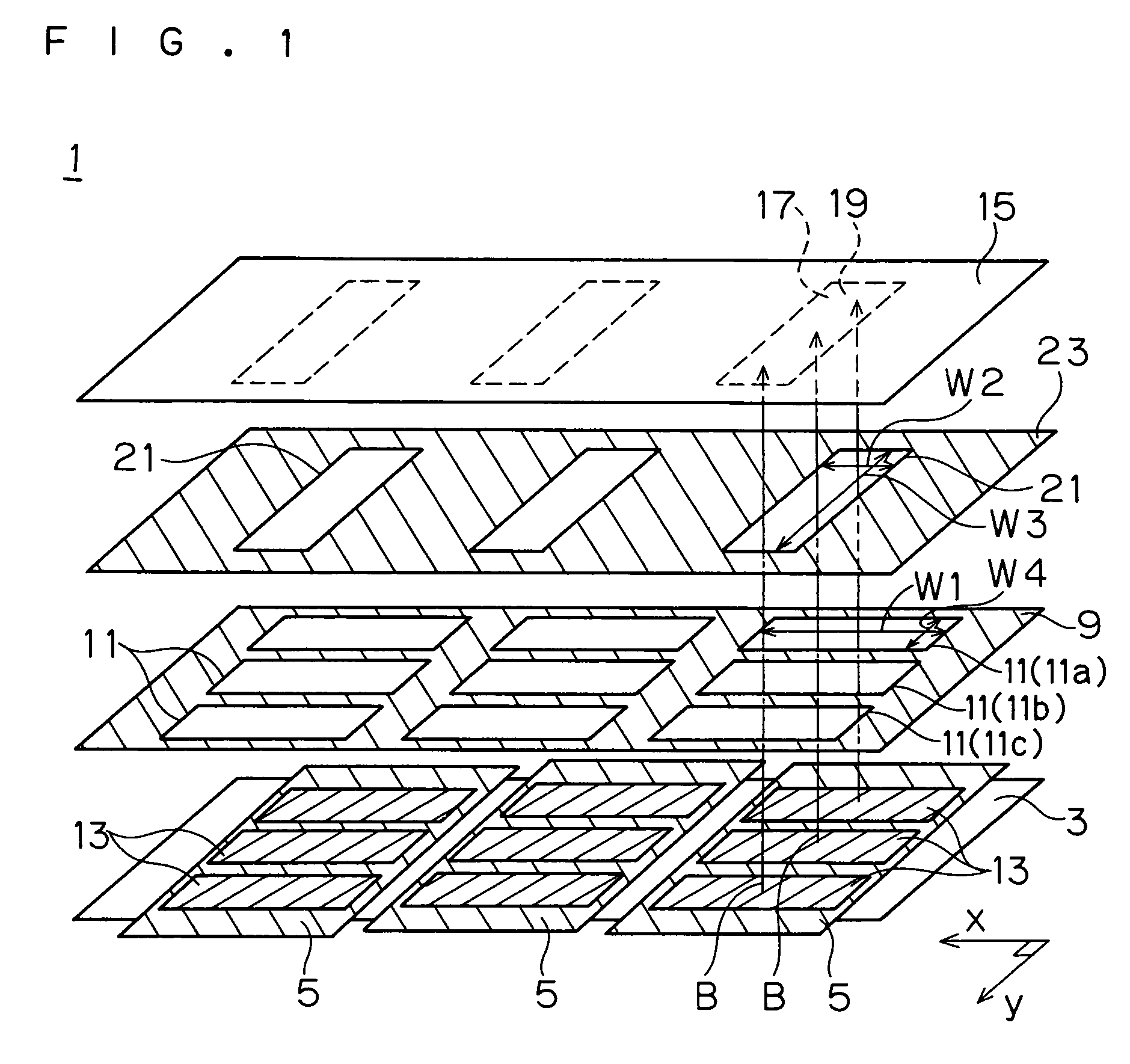

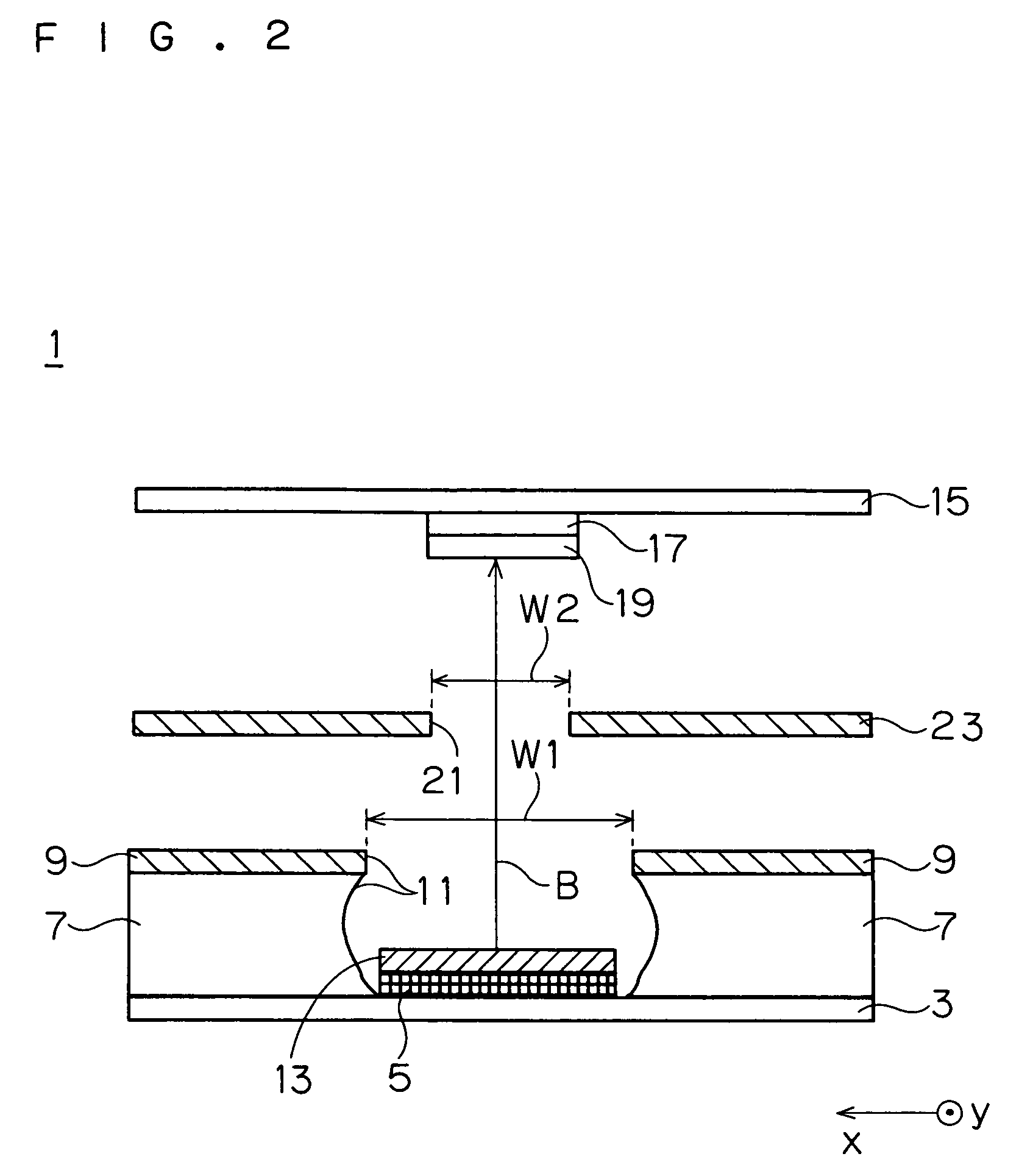

[0023]As shown in FIGS. 1 and 2, a field emission display device 1 according to this preferred embodiment of the present invention includes a cathode substrate 3, cathode electrodes 5 formed on the cathode substrate 3, flat electron emission material layers 13 formed on the cathode electrodes 5 and substantially similar in shape to, for example, openings 11 of a control electrode 9 to be described later, the control electrode 9 located at the front of the electron emission material layers 13 and having the openings 11 opposed to the electron emission material layers 13, a transparent anode substrate 15 located at the front of the control electrode 9, for example, transparent anode electrodes 17 formed on the rear surface of the anode substrate 15, phosphors 19 formed on the anode electrodes 17, and a shield electrode 23 located between the control electrode 9 and the anode electrodes 17 and formed with electron pass apertures 21 through which an electron beam B flowing from the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com