Narrow composition distribution polyvinylidene fluoride RECLT films, processes, articles of manufacture and compositions

a polyvinylidene fluoride and composition technology, applied in the direction of polarising elements, group 3/13 element organic compounds, synthetic resin layered products, etc., can solve the problems of low ph of electrolyte, degradation of transparent electrically conductive materials, drawback of generating hydrogen gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

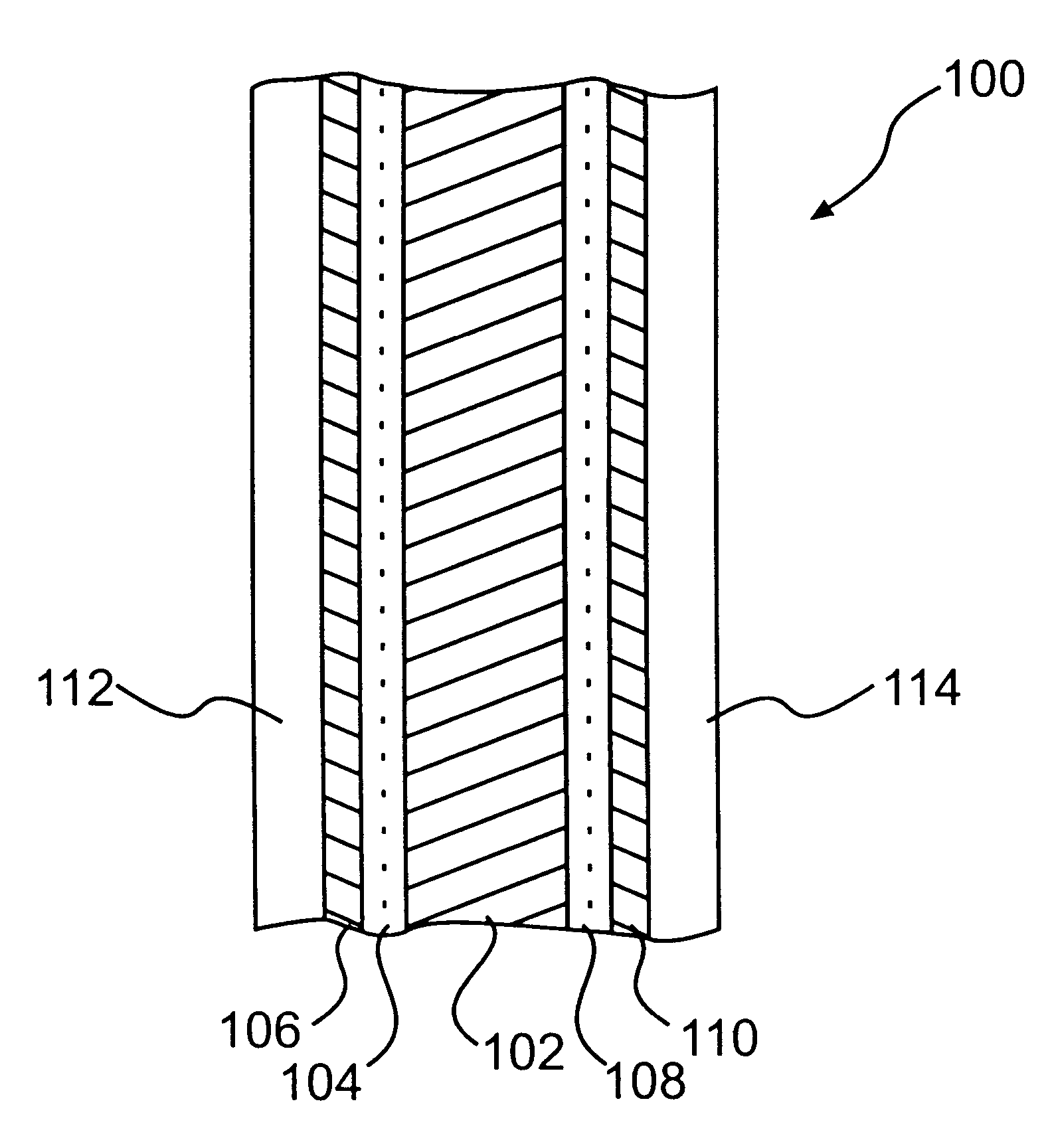

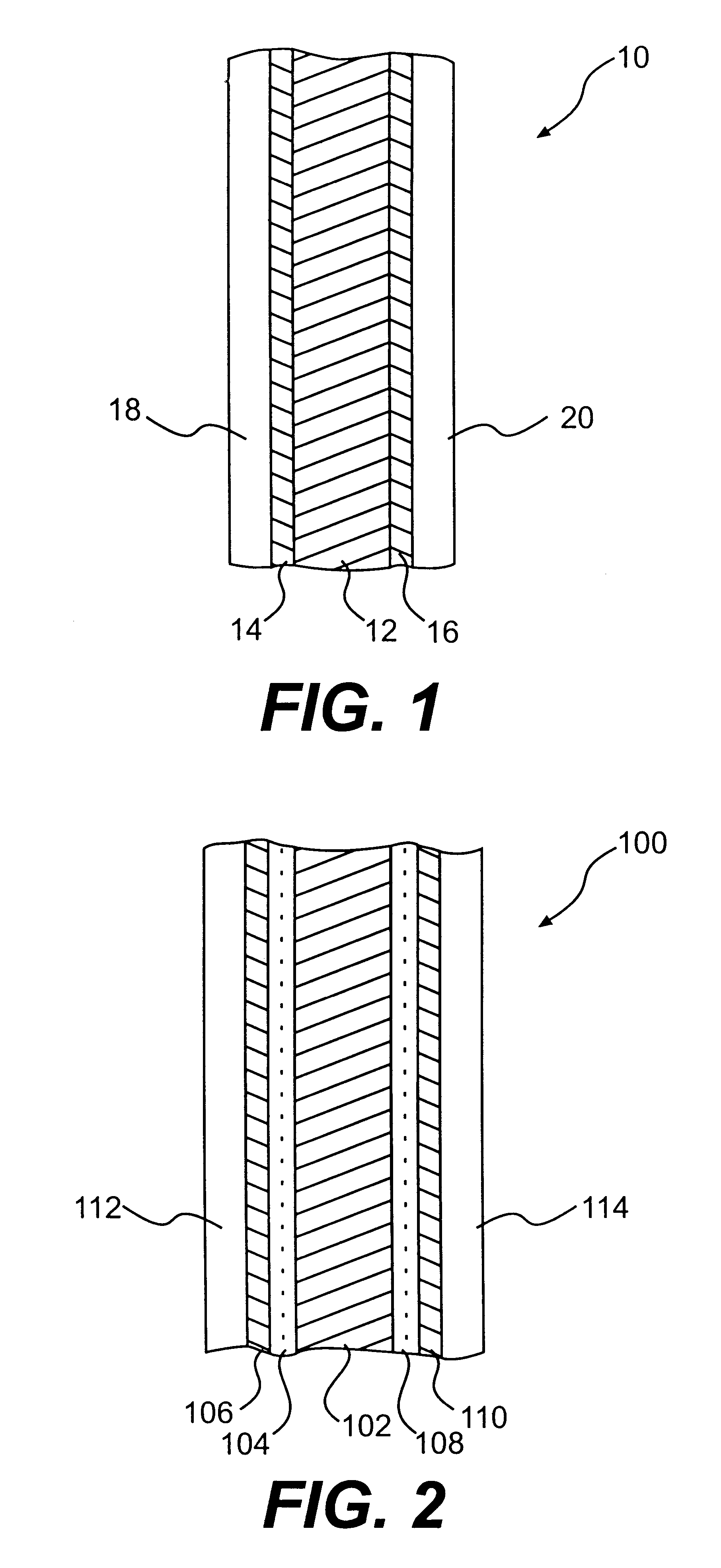

Image

Examples

example 1

A 10 wt % solution of KYNAR FLEX 2801, a broad distribution VF.sub.2 -HFP (vinylidene fluoride-hexafluoropropylene) copolymer with an average of about 10 wt % HFP was dissolved in N-methyl pyrrolidinone at 60.degree. C. for 1 hour. The solution was then cast on glass and dried in a convection oven at 165.degree. C. for 30 minutes. The resulting dry film was about 15 .mu.m thick. It was peeled from the substrate and its optical clarity measured using a BYK-Gardner haze-gard plus instrument. It was found to have a clarity of 94.9%.

example 2

A 10 wt % solution of a narrow distribution composition VF.sub.2 -HFP copolymer (copolymer 1) with an average of about 7 wt % HFP was dissolved in N-methyl pyrrolidinone at 60.degree. C. for 1 hour. The solution was then cast on glass and dried in a convection oven at 165.degree. for 30 minutes. The resulting dry film was about 15 .mu.m thick. It was peeled from the substrate and its optical clarity was measured using a BYK-Gardner haze-gard plus instrument. It was found to have a clairty of about 97.8%.

example 3

A 10 wt % solution of a narrow distribution composition VF.sub.2 -HFP copolymer (copolymer 2) with an average of about 15 wt % HFP was dissolved in N-methyl pyrroilidinone at 60.degree. C. for 1 hour. The solution was then cast on glass and dried in a convection oven at 165.degree. C. for 30 minutes. The resulting dry film was about 15 .mu.m thick. It was peeled from the substrate and its optical clarity was measured using a BYK-Gardner haze-gard plus instrument. It was found to have a clarity of 98.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| DSC melting points | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com