Heat recovery procedure

a heat recovery and heat recovery technology, applied in the field of improved heat recovery procedures, can solve the problems of glycol becoming a pollution problem, heat loss of cooling water,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

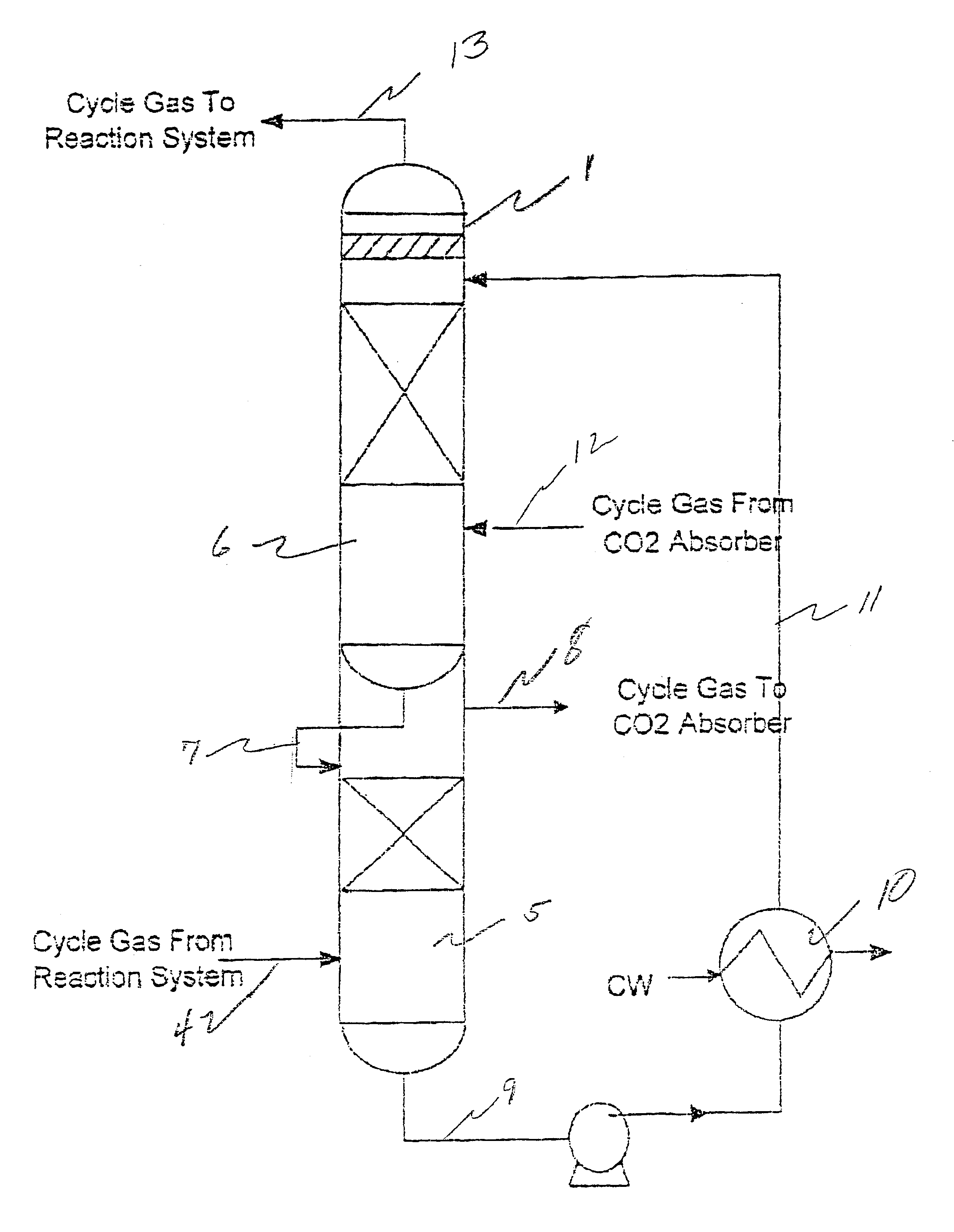

In a 600,000 MT / YR ethylene oxide plant the stream 4 cycle gas from the reaction system after ethylene oxide scrubbing is 13,300 kg-moles / hr for a low CO.sub.2 design with a typical composition of 2.2 vol % CO.sub.2 and a water content of 0.39 vol %. The residual ethylene oxide content is 30 vol ppm. The temperature is 41.degree. C. and the pressure is 20.0 bars. The water circulation stream 7 would be approximately 70,400 kg-moles / hr at a temperature of 43.degree. C. The circulation water stream after it leaves the gas cooling section 6 has been heated to 79.3.degree. C. This water is contacted with the cycle gas ie. packed section 5 of presaturator 1. The gas is heated to 77.degree. C. and the liquid is cooled to 57.degree. C. Approximately 28.2 million kcals are transferred from the liquid to the gas. The gas temperature is raised to 77.degree. C. and the water content is raised to 2.12 vol. %. The ethylene oxide content of the gas feed to the CO.sub.2 absorber is reduced by 60%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com