Anti-static roll cover

a roll cover and anti-static technology, applied in the field of anti-static roll cover, can solve the problems of static buildup on preprinted sheet material, historic and troublesome problem for printers, web/sheet guidance problems, and particulate contamination on the surface of preprinted sheet material, etc., to achieve the effect of convenient installation, low cost and disposabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

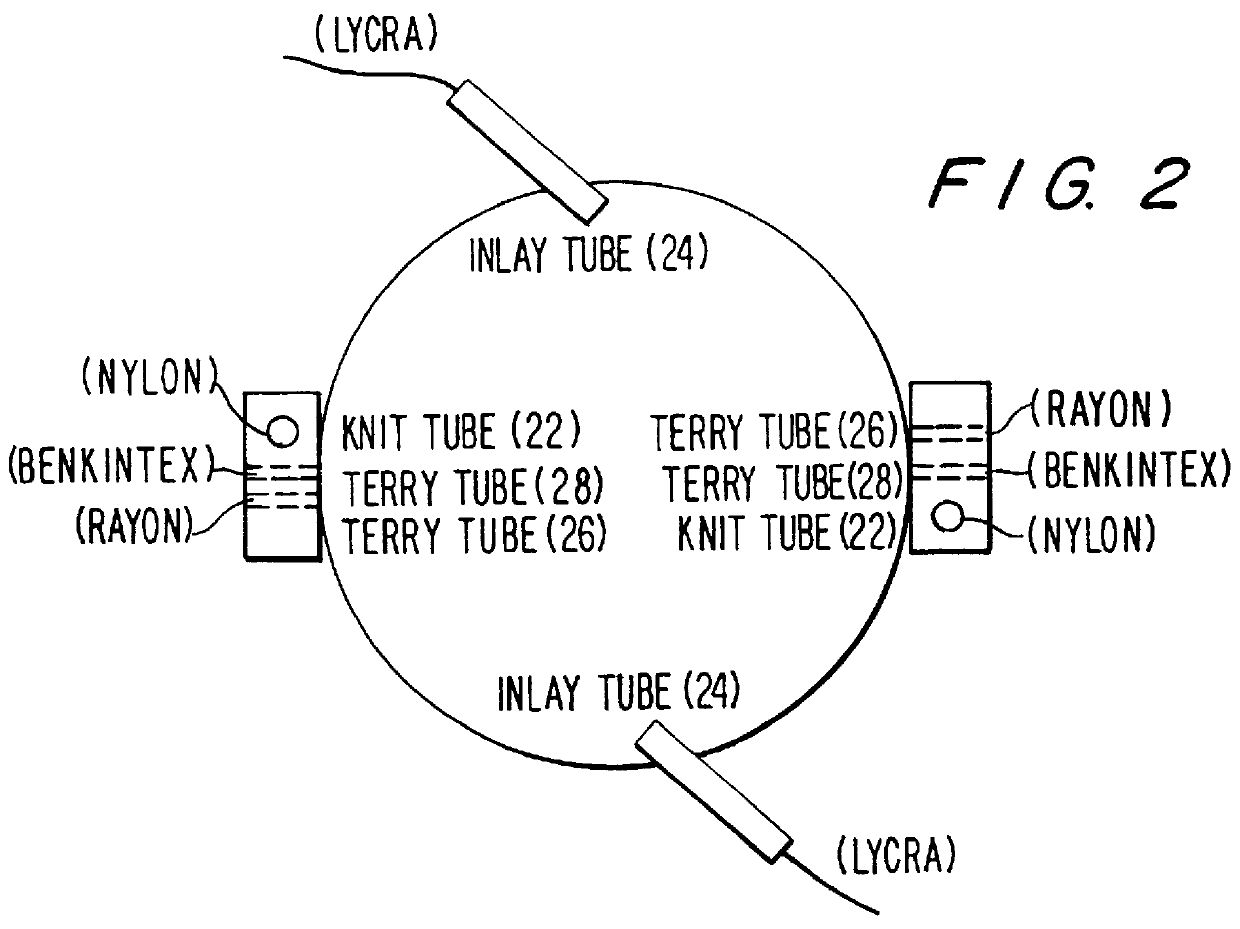

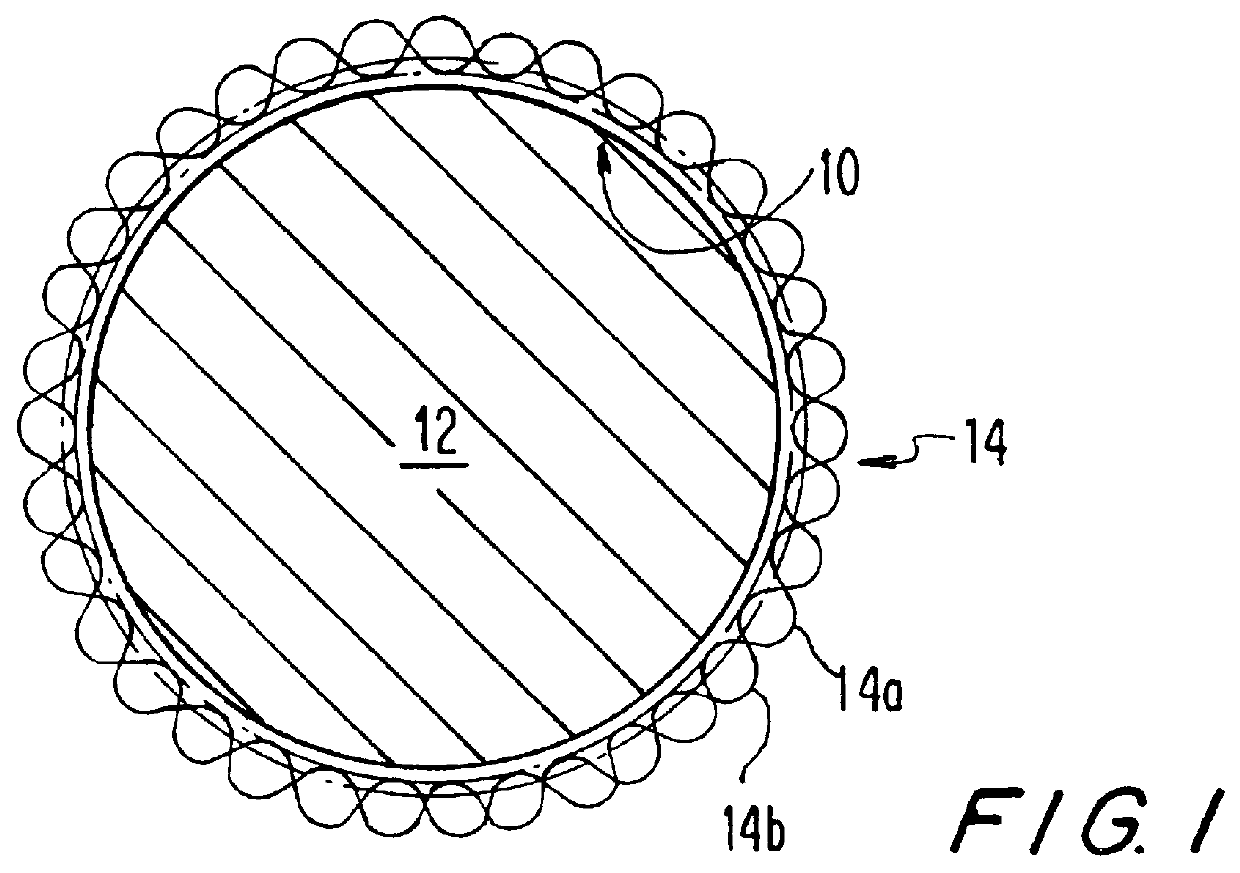

Referring to FIG. 1, a transfer roll cover in accordance with the present invention has an inner surface 10 made of conductive and elastic material that fits onto and makes conductive contact with a transfer roll 12 which is made of metal or other conductive material. Preferably, the inner surface 10 includes a combination of elastic yarns to provide elasticity and nylon yarns to provide strength. The elastic yarns ensure that the sleeve fits snugly around the transfer roll 12. A suitable elastic yarn is sold under the tradename 420 Denier LYCRA.TM. by Dupont Company in the U.S. A suitable nylon yarn is sold under the tradename 70 Denier Two-Ply Nylon by Jefferson Mills, Inc., in the U.S. An alternate inner surface construction can utilize heat-shrinkable yarn or other material (in place of the elastic yarn) which is activated by applying heat to the cover after the cover is installed on the roll.

The outer surface 14 of the roll cover is made of a composite of looped yarns which are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com