Control device and control method for internal combustion engine

a control device and control method technology, applied in the direction of electric control, ignition automatic control, machines/engines, etc., can solve the problems of reducing the combustion performance of the main combustion chamber, reducing the combustion performance of the pre-combustion chamber, and limiting the use of only hardware measures, so as to suppress the reduction of combustion performance and efficiently exhausted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0019]Hereinafter, an internal combustion engine (engine) according to the first embodiment of the present disclosure will be described with reference to the drawings.

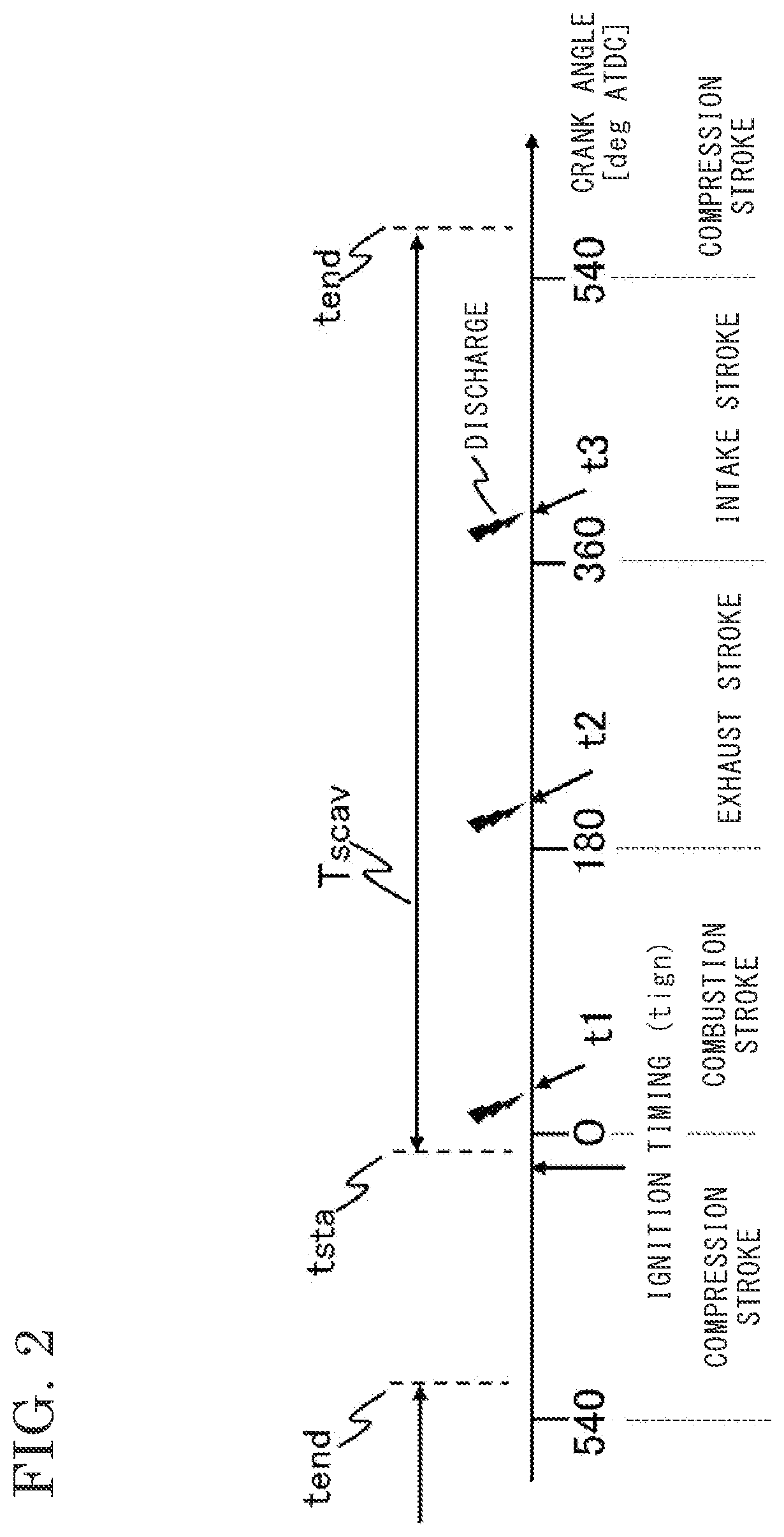

[0020]FIG. 1 is a schematic configuration diagram of the internal combustion engine according to the first embodiment. In FIG. 1, an internal combustion engine 100 includes: a main combustion chamber 105; a pre-combustion chamber 102 having, between the pre-combustion chamber 102 and the main combustion chamber 105, at least one orifice 101 communicating with the main combustion chamber 105; a spark plug 103 which is located in the pre-combustion chamber 102 and has an electrode (not shown), and which generates spark discharge between the electrode and a ground electrode by high voltage applied; an ignition coil 104 for providing high voltage to the spark plug 103; a first control device 106 which controls operation of the ignition coil 104 to generate spark discharge at the spark plug 103; and a second control device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com