Fan filter unit with integrated heater

a filter unit and heater technology, applied in lighting and heating apparatus, heating types, ventilation systems, etc., to achieve the effect of reducing the space required for the fan filter unit and the heater, reducing the overheating and/or tripping of the blower motor, and more spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

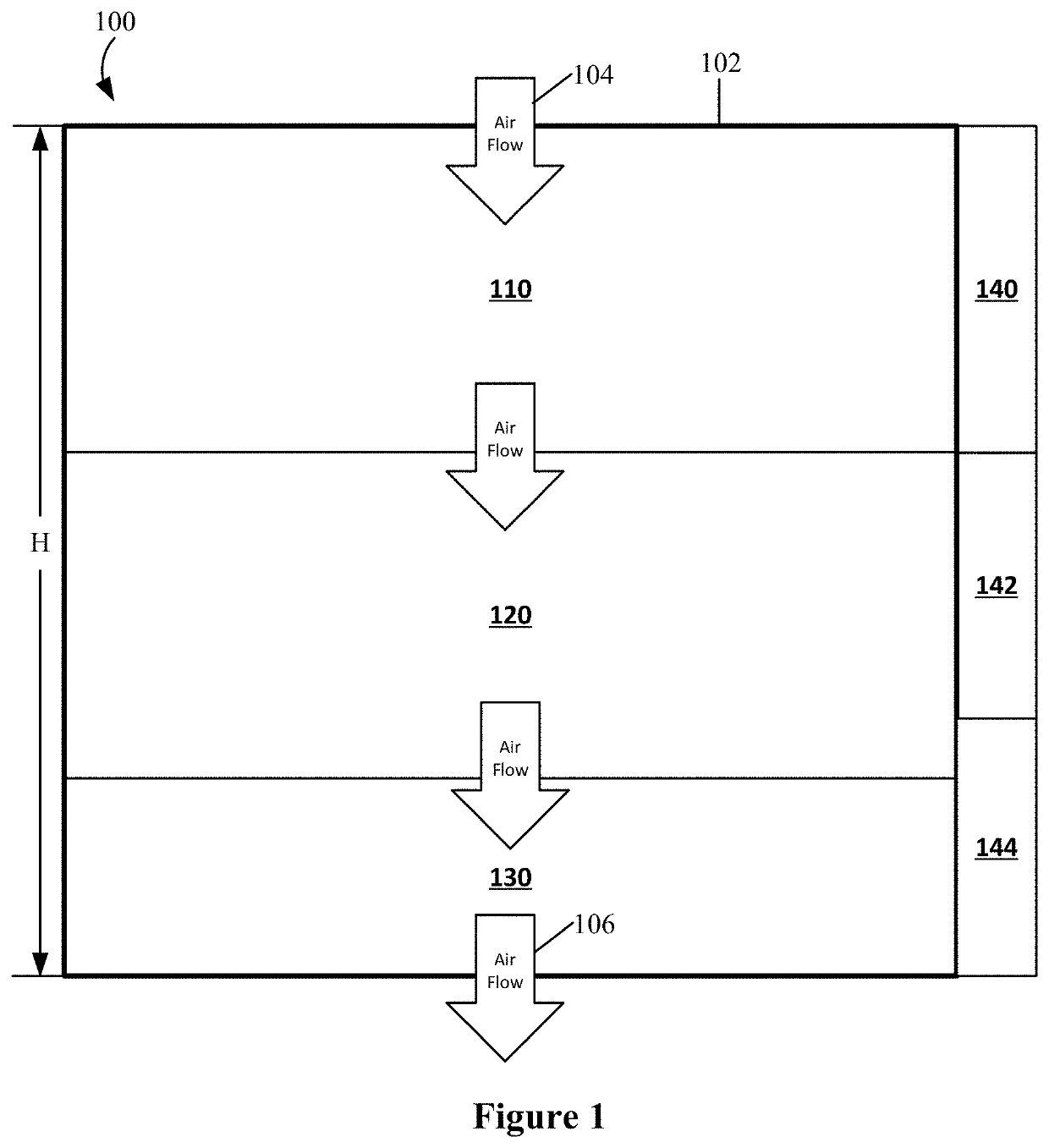

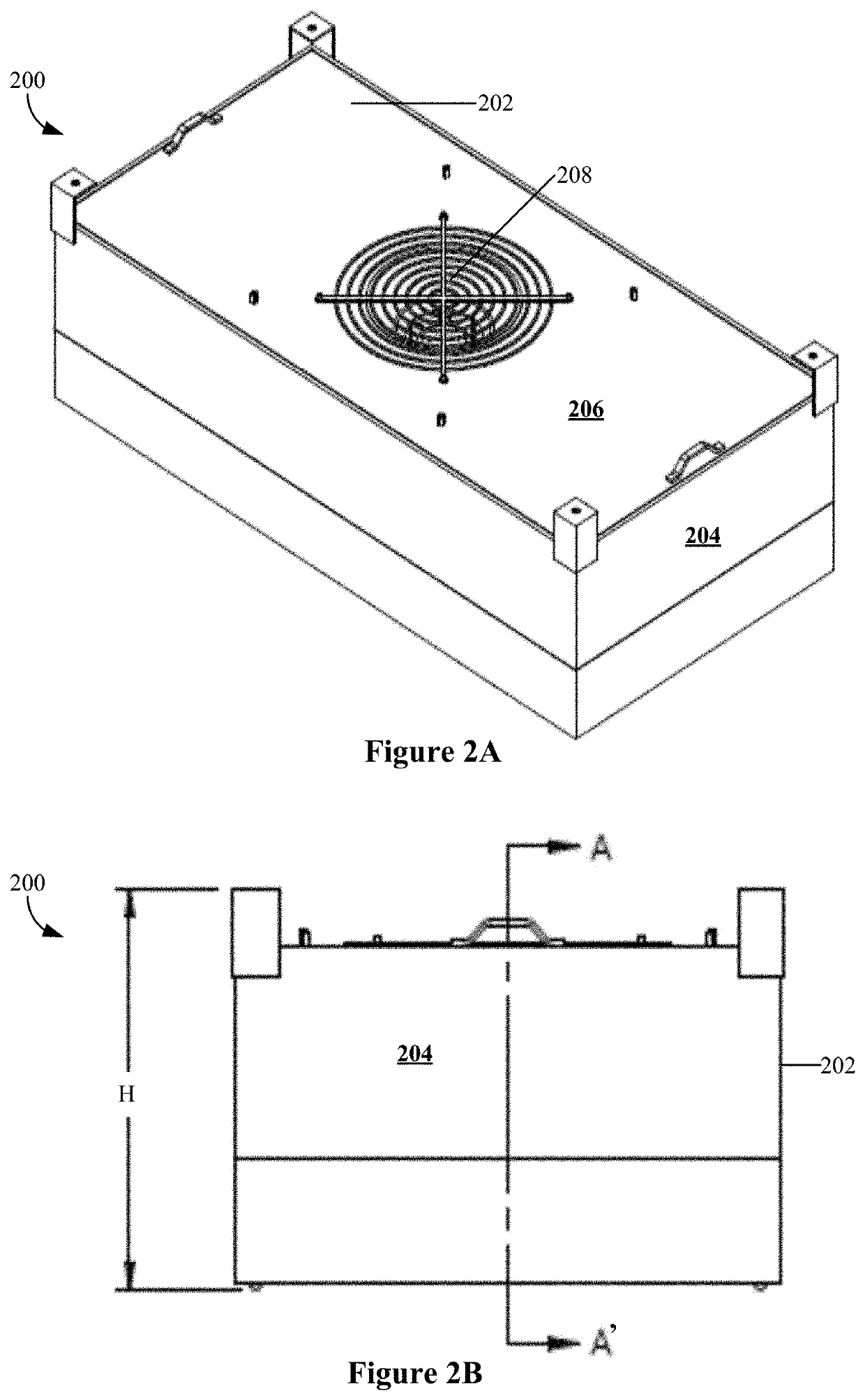

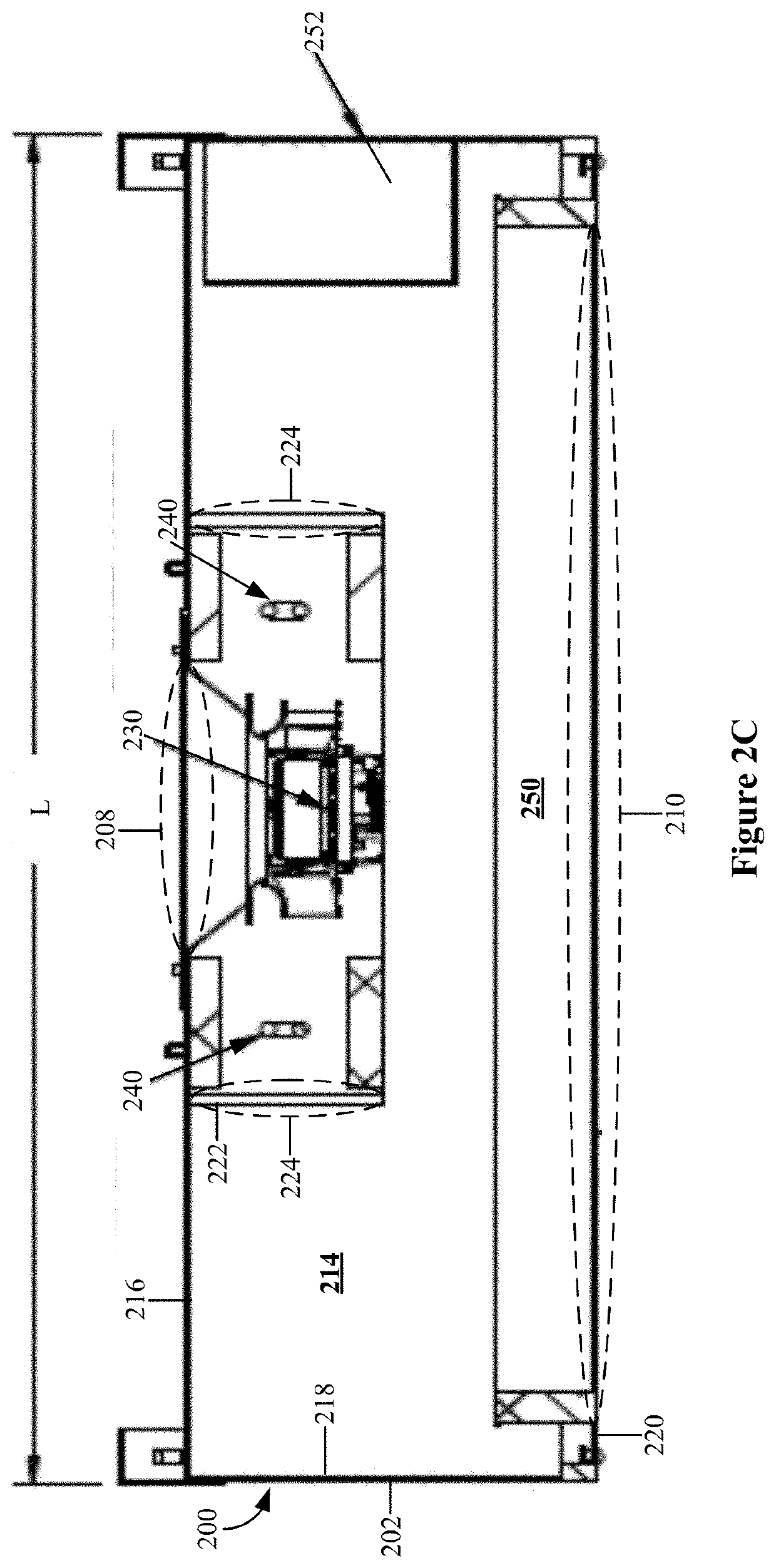

[0015]Fan filter units with an integrated heater are provided. By integrating a heater into a traditional fan filter unit used in mobile and / or modular cleanrooms and / or laboratories, the overall amount of space required for the fan filter unit and the heater is reduced. Indeed, fan filter units with an integrated heater provided herein are designed to be placed within the ceiling, or even a wall, allowing for more space that can be utilized for other functions that would normally be occupied by the fan filter unit and / or the heater unit, which is even more critical in cleanrooms and / or laboratories that have limited space such as mobile and / or modular cleanrooms and / or laboratories. The placement of the heater (e.g., downstream of the blower motor) reduces overheating and / or tripping of the blower motor. The placement of the air filter (e.g., proximal / flush with the ceiling) allows for ceiling-side access to the components within the fan filter unit with the integrated heater, incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com