Suction rod assembly for well fluid extraction and related methods

a well fluid extraction and sucker rod technology, applied in the direction of positive displacement liquid engines, well accessories, liquid fuel engines, etc., can solve the problems of inability to recover linear scoring of barrels or plungers, requires replacement, and non-linear abrasions on the plunger surface. , to achieve the effect of reducing the number of plungers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Reference will now be made in detail to certain embodiments of the invention, examples of which are illustrated in the accompanying drawings. While the invention will be described in reference to these embodiments, it will be understood that they are not intended to limit the invention. To the contrary, the invention is intended to cover alternatives, modifications, and equivalents that are included within the spirit and scope of the invention. In the following disclosure, specific details are given to provide a thorough understanding of the invention. However, it will be apparent to one skilled in the art that the present invention may be practiced without all of the specific details provided.

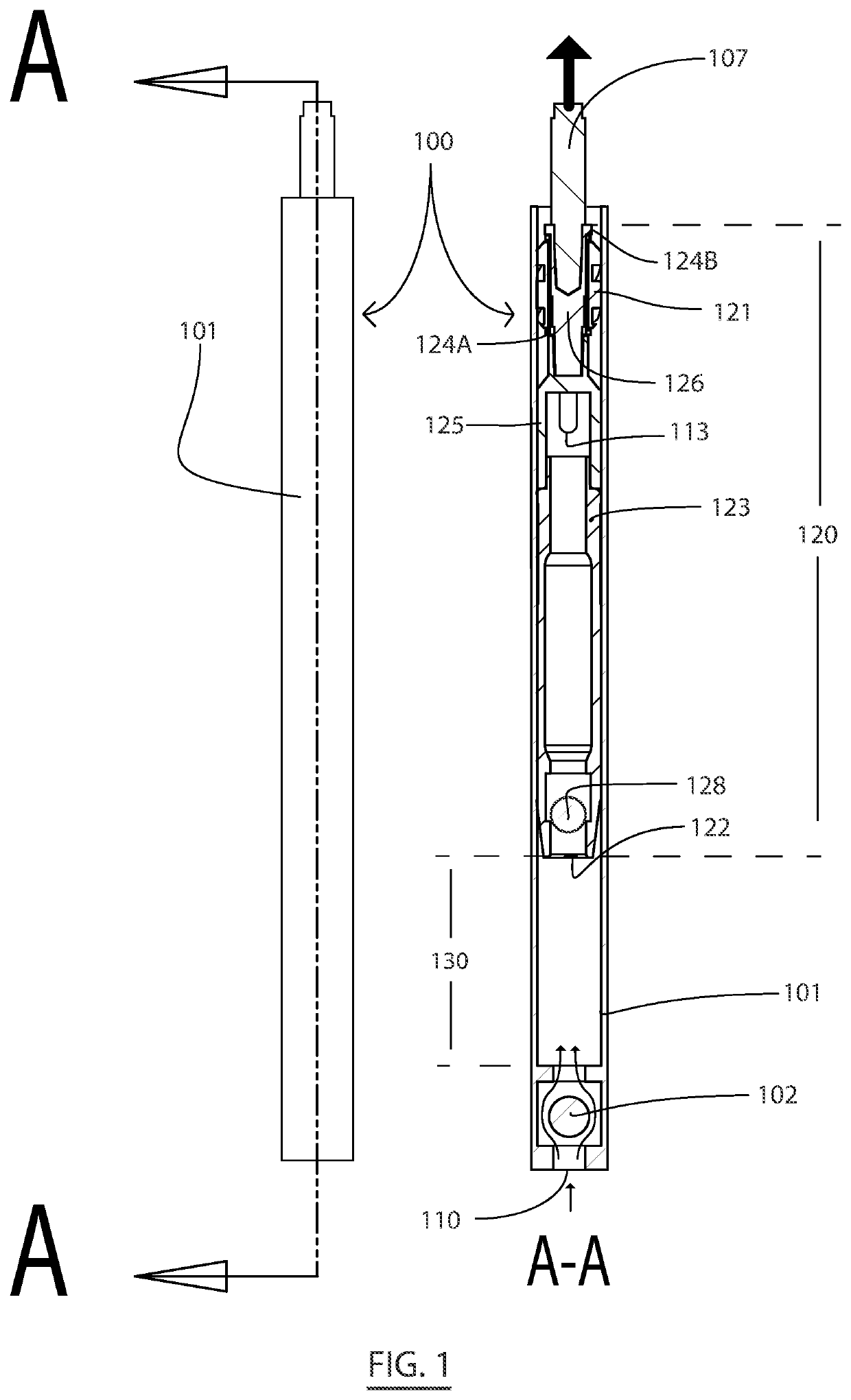

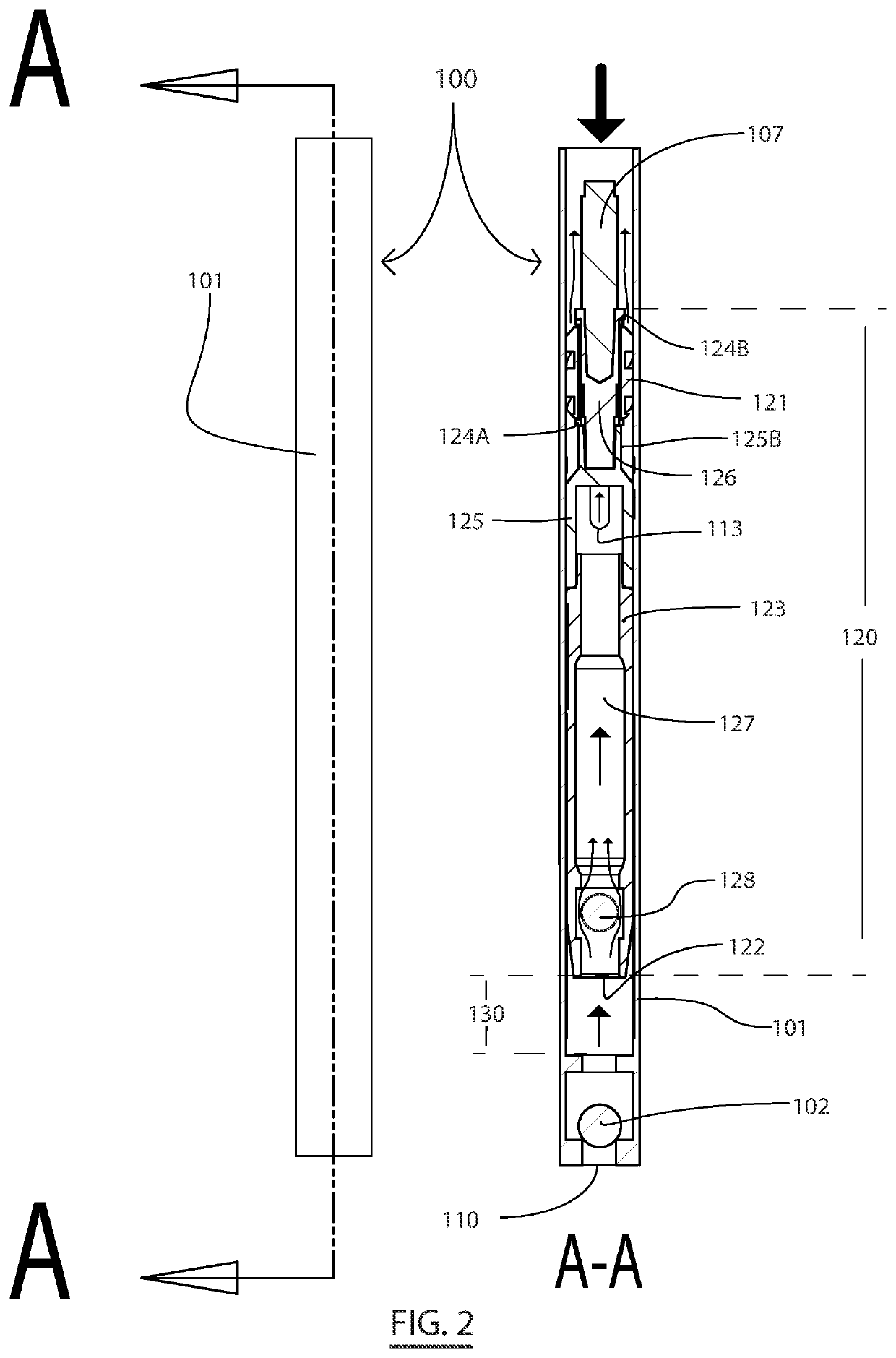

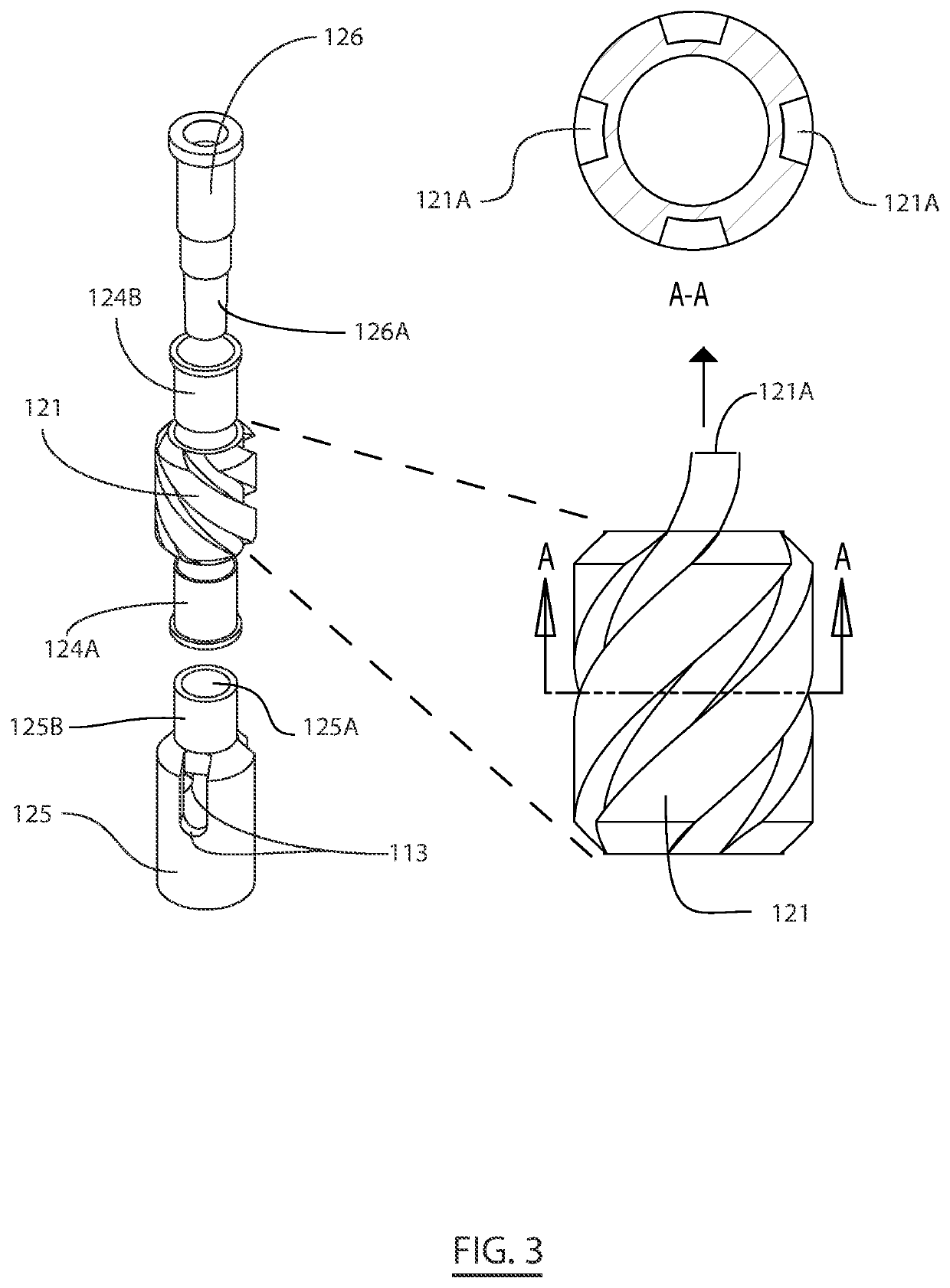

[0038]The present invention concerns a Suction Pump Rod (SPR) system that may be incorporated into a downhole pumping system or other pumping equipment. FIGS. 1-7 provide views of an exemplary SPR assembly 100. FIGS. 1-4 provide views of the SPR assembly 100 incorporating a plunger assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com