Ophthalmic solution container

a container and solution technology, applied in the field of self-standing containers, can solve the problems of low fluidity poor loading efficiency of containers filled with contents, and difficulty in use, and achieve the effect of strength and disposability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will be described below with reference to the drawings on the basis of preferred embodiments.

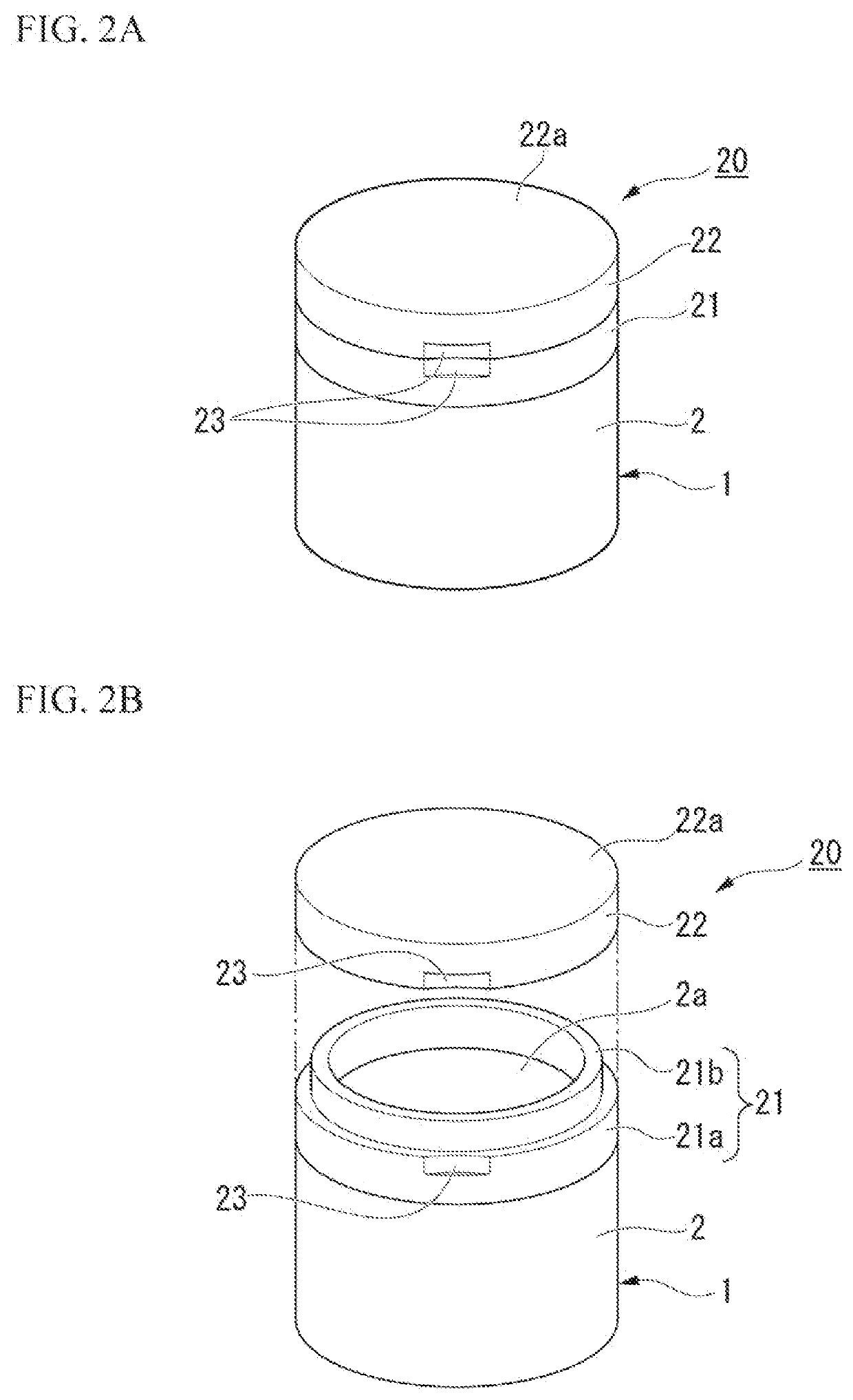

[0031]FIGS. 1A and 1B show a container 10 according to a first embodiment. The container 10 includes a container body 1 having an opening part 2a at an upper end of a tubular member 2, an annular member 11 that is bonded to the upper end of the tubular member 2, and a lid member 12 that seals the opening part 2a to be openable and closable. The lid member 12 has a base part 14 that can be bonded to the annular member 11 and a top part 15 that is coupled to the base part 14 via a hinge 13 to be openable and closable. The base part 14 has a ring shape and the top part 15 has a closed top surface part 15a. When sealing the contents is not required, a hole may be provided in the top surface part 15a or a mesh, a grid, or the like may be provided thereon.

[0032]In the first embodiment, the top part 15 may be constituted to be coupled to the annular member 11 via the hin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| outer diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com