Modular docking system for electrosurgical equipment

a technology of electrosurgical equipment and module, applied in the field of surgical systems, can solve the problems of affecting the introduction of new technology, affecting the operation room, and occupying valuable space by new modules or devices, and achieve the effect of reducing footprint and less cabling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]Referring to the figures, wherein like numeral refer to like parts throughout, there is seen in FIG. 1 an electrosurgical system 10 having two or more interconnected modules, shown as an electrosurgical unit 12 and a smoke evacuator 14. Electrosurgical unit 12 and smoke evacuator 14 are interconnected using an upwardly facing docking interface 16 of smoke evacuator 14 that mates with a corresponding downwardly docking interface 20 of electrosurgical unit 12.

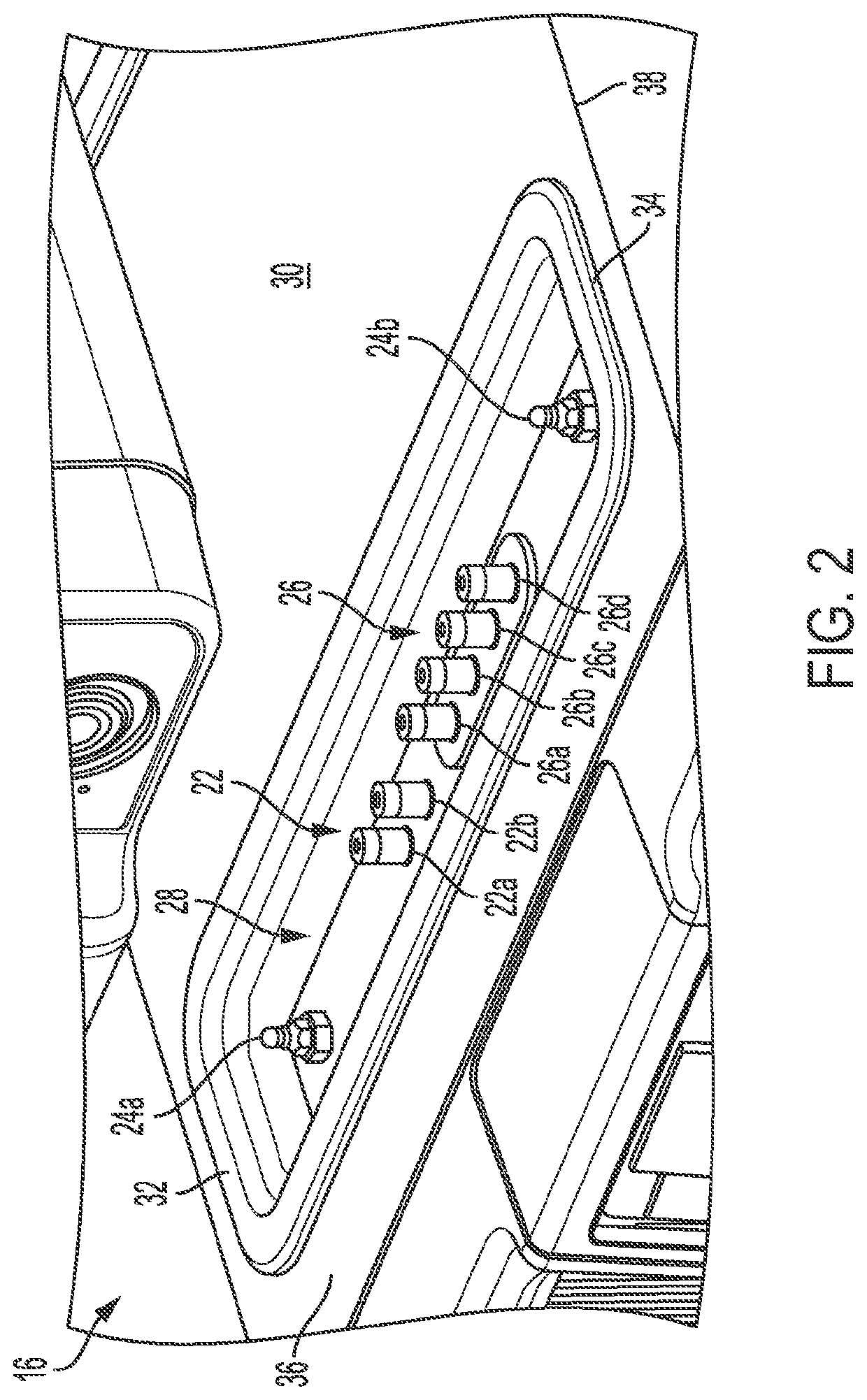

[0013]Referring to FIG. 2, docking interface 16 includes a series of power connectors 22, ground studs 24, and communication ports 26, shown as male style connectors positioned within a recessed portion 28 of the housing 30 of smoke evacuator 14. More specifically, docking interface 16 comprises a pair of ground studs 24a and 24b positioned at opposing ends 32 and 34 of recessed portion 28. Recessed portion 28 extends transversely across a forward portion 36 of the upper surface 38 of housing 30. Ground studs 24a and 24b ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com