Temperature control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

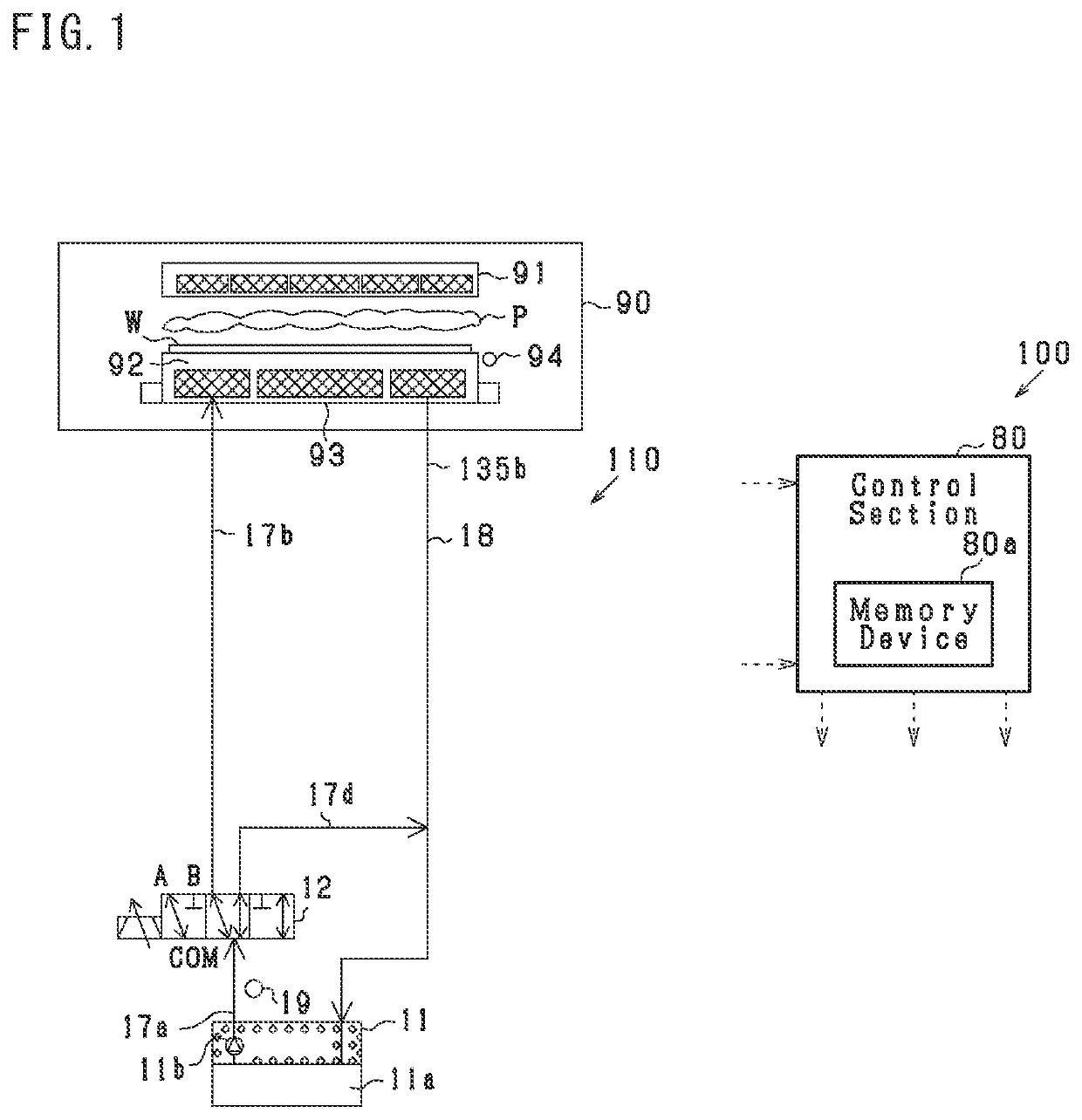

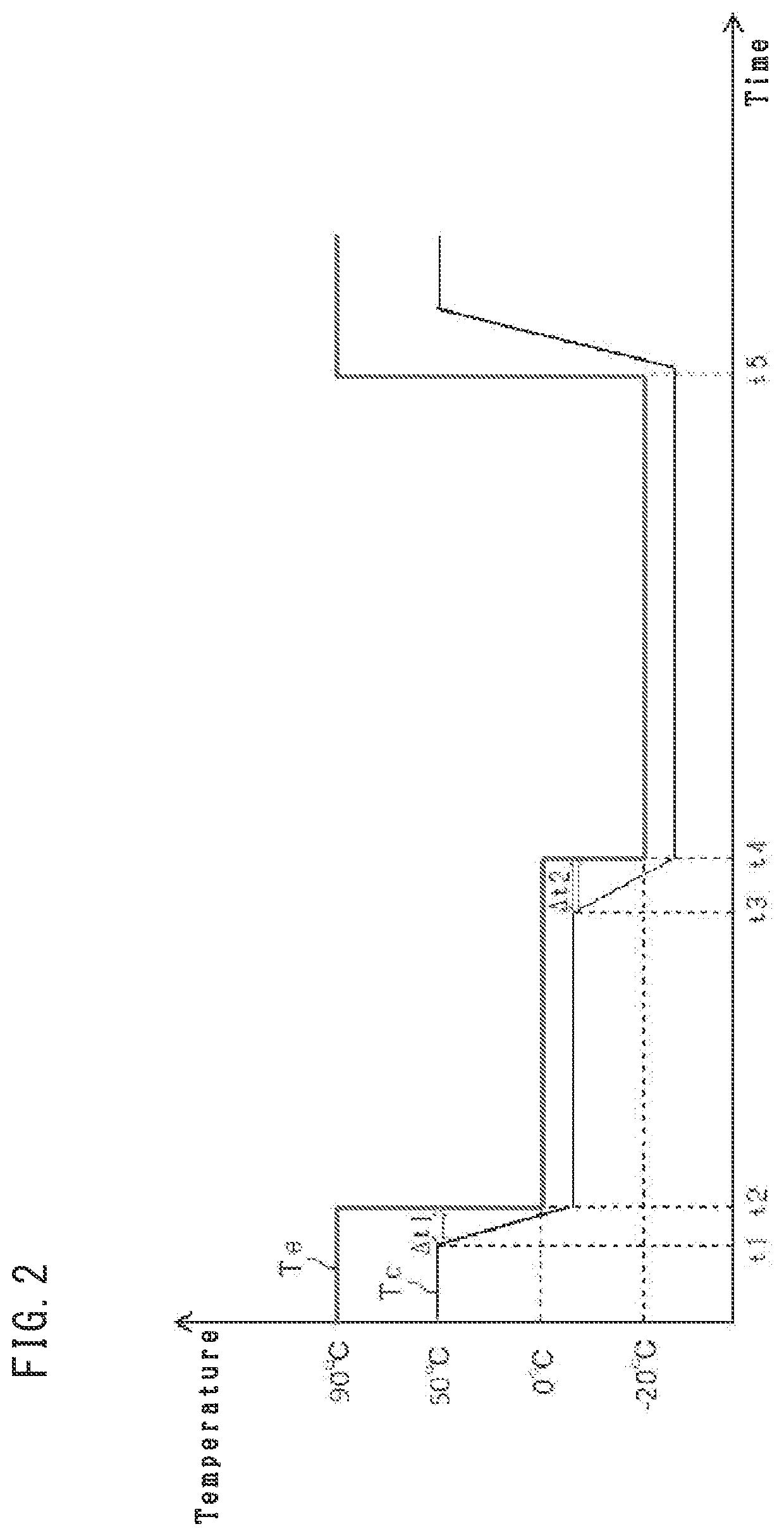

[0058]A first embodiment will now be described with reference to the drawings. The first embodiment is embodied as a temperature control system for controlling the temperature of a lower electrode (control target) of a semiconductor manufacturing apparatus.

[0059]As shown in FIG. 1, a temperature control system 100 includes a first circulation circuit 110, a control section 80, etc.

[0060]The first circulation circuit 110 is a circuit through which a first heat transfer medium circulates. The first heat transfer medium (heat transfer medium) is, for example, a liquid composed of ethylene glycol (60%) and water (40%). The first heat transfer medium is relatively inexpensive. The first circulation circuit 110 includes a first chiller 11, a temperature sensor 19, a first distribution valve 12, etc.

[0061]The first chiller 11 (adjustment apparatus) includes a tank 11a, a pump 11b, etc. The first chiller 11 can adjust the temperature of the first heat transfer medium to −25° C. to 95° C. Th...

second embodiment

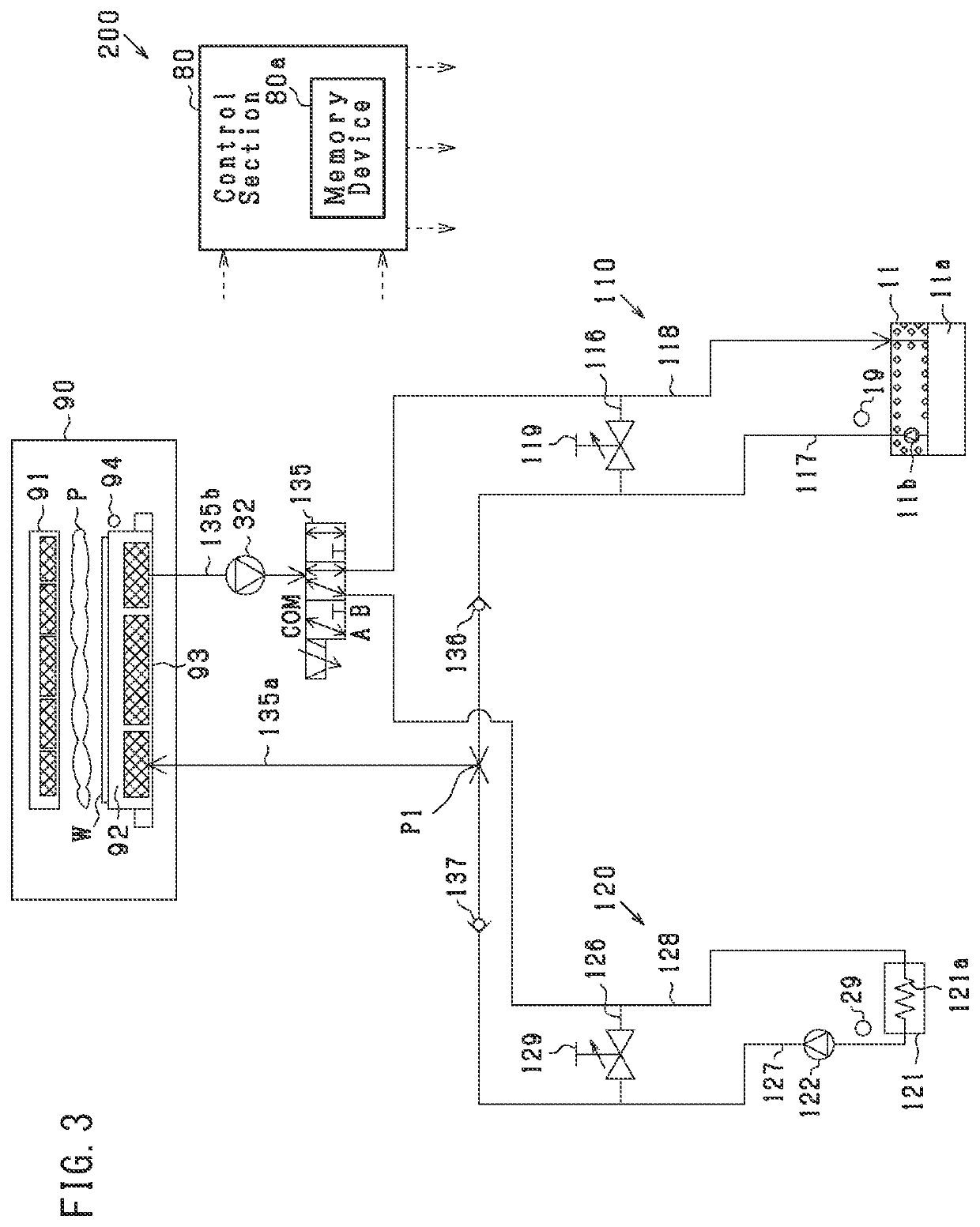

[0081]A second embodiment will now be described. In the following description, the difference between the second embodiment and the first embodiment will be mainly described. Notably, portions identical with those of the first embodiment are denoted by the same reference numerals, and their description will not be repeated.

[0082]As shown in FIG. 3, a temperature control system 200 includes a first circulation circuit 110, a second circulation circuit 120, the control section 80, etc. The first circulation circuit 110 is a circuit through which the above-described first heat transfer medium circulates. The second circulation circuit 120 is a circuit through which a second heat transfer medium circulates. The second heat transfer medium is the same liquid as the first heat transfer medium. Namely, the first circulation circuit 110 and the second circulation circuit 120 are circuits through which the above-described first heat transfer medium (common heat transfer medium) used in commo...

third embodiment

[0103]A third embodiment will now be described. In the following description, the difference between the third embodiment and the second embodiment will be mainly described. Notably, portions identical with those of the first and second embodiments are denoted by the same reference numerals, and their description will not be repeated.

[0104]As shown in FIG. 4, a temperature control system 300 of the present embodiment is identical with the temperature control system 200 of the second embodiment except that the second distribution valve 135 is replaced with a third distribution valve 335.

[0105]The third distribution valve 335 (adjustment section) is a four-way valve having a common port, an H port, a B port, and a C port. The flow passage 118 is connected to the C port. The flow passage 118 is connected to the tank 11a of the first chiller 11. A flow passage 239 is connected to the B port. The flow passage 239 is connected to the flow passage 135a at the merging point P1. A third chec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com