Flow Diversion Valve for Downhole Tool Assembly

a technology of flow diversion valve and tool assembly, which is applied in the direction of tubing catchers, earth-moving drilling, and accessories in the wellbore/well. it can solve the problem of reducing the total strength of the connection holding the casing in the wellbor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

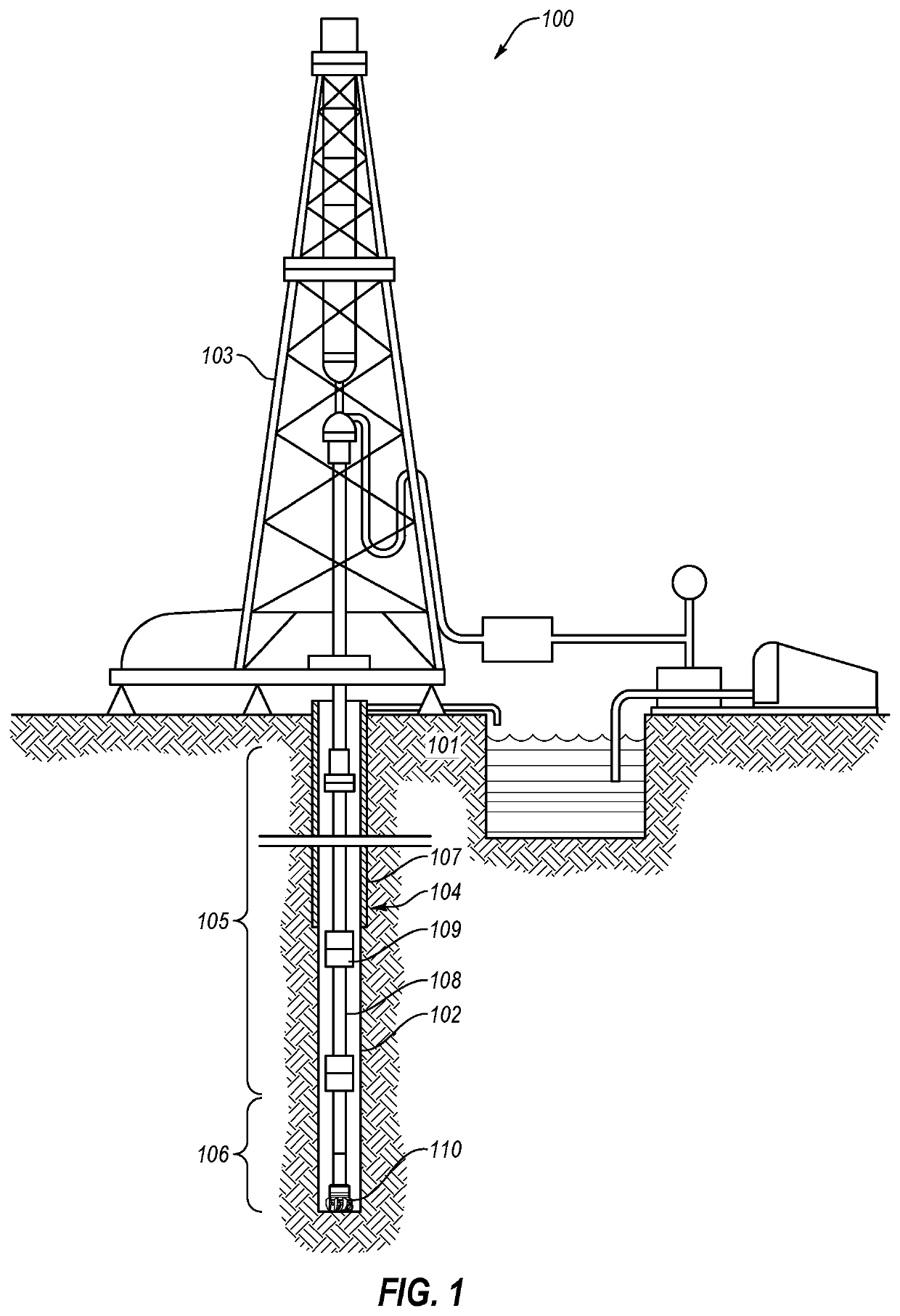

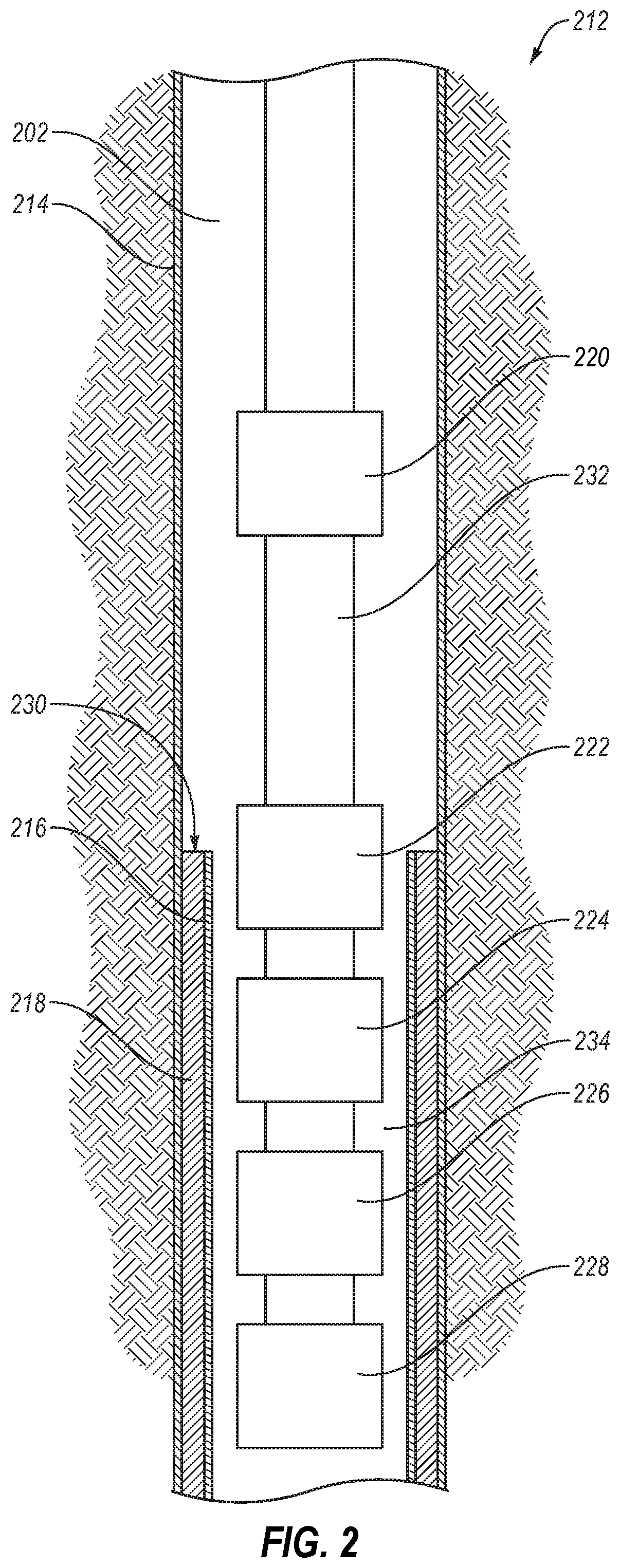

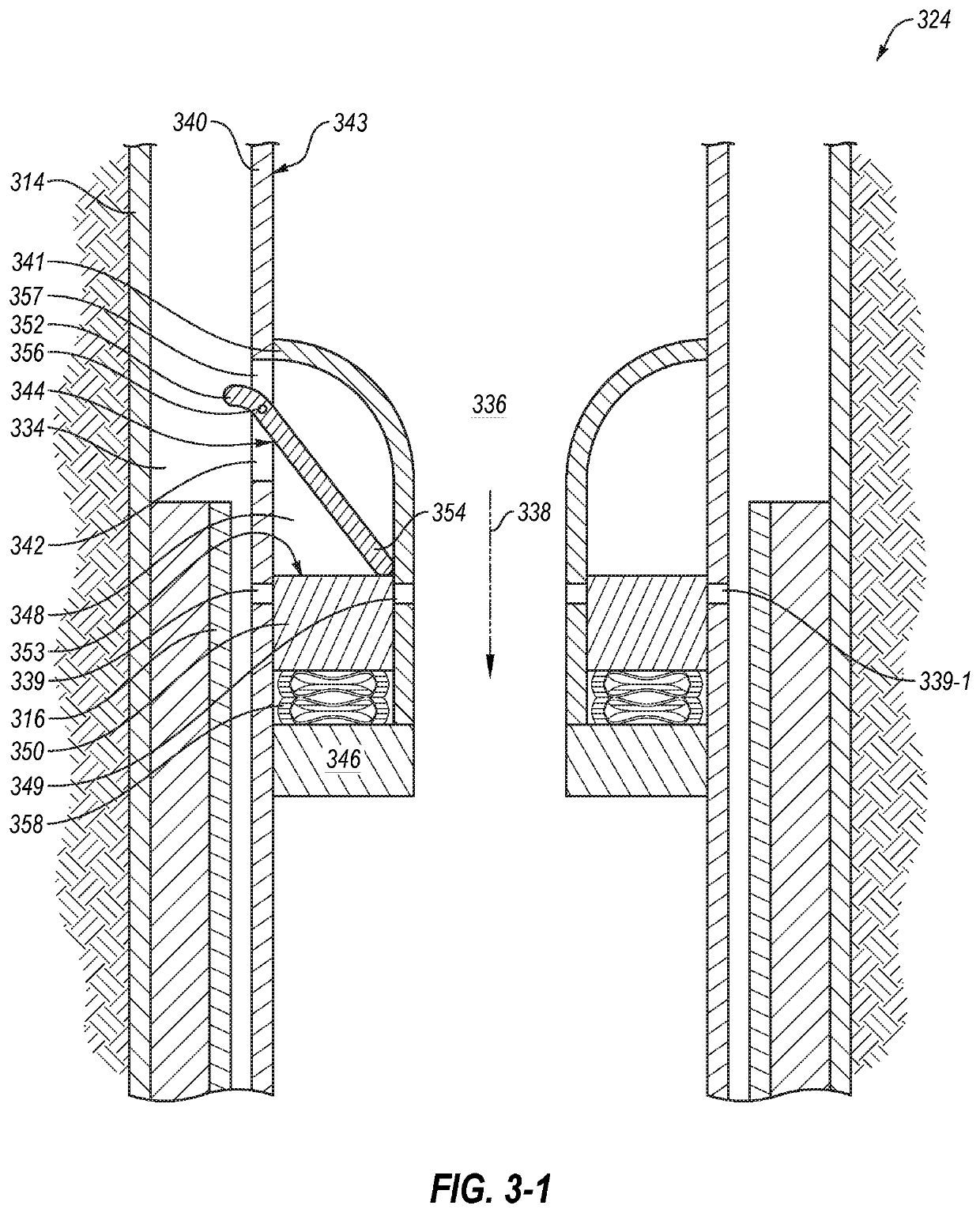

[0029]This disclosure generally relates to devices, systems, and methods for removing a casing from a wellbore. The system includes a flow diversion valve. When the flow diversion valve is closed, a fluid flow may drive a mud motor, which powers a casing cutter. To open the flow diversion valve, the flow diversion valve is lowered below a stump of an inner casing. When the flow diversion valve is open, at least a portion of the fluid flow may be diverted to the annulus between the flow diversion valve and the casing. The portion of the fluid flow diverted to the annulus is such that, downhole of the flow diversion valve, the fluid flow is insufficient to drive the mud motor. Thus, when the flow diversion valve is open, a hydraulically powered jack may pull on a spear connected to the casing without driving the mud motor. Therefore, by raising and lowering the flow diversion valve above and below the stump of the inner casing, the casing removal system may cycle between pulling on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com