Method for operating a filter press and a filter press

a filter press and filter technology, applied in the direction of filtration separation, separation process, chemistry apparatus and process, etc., can solve the problem of additional maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

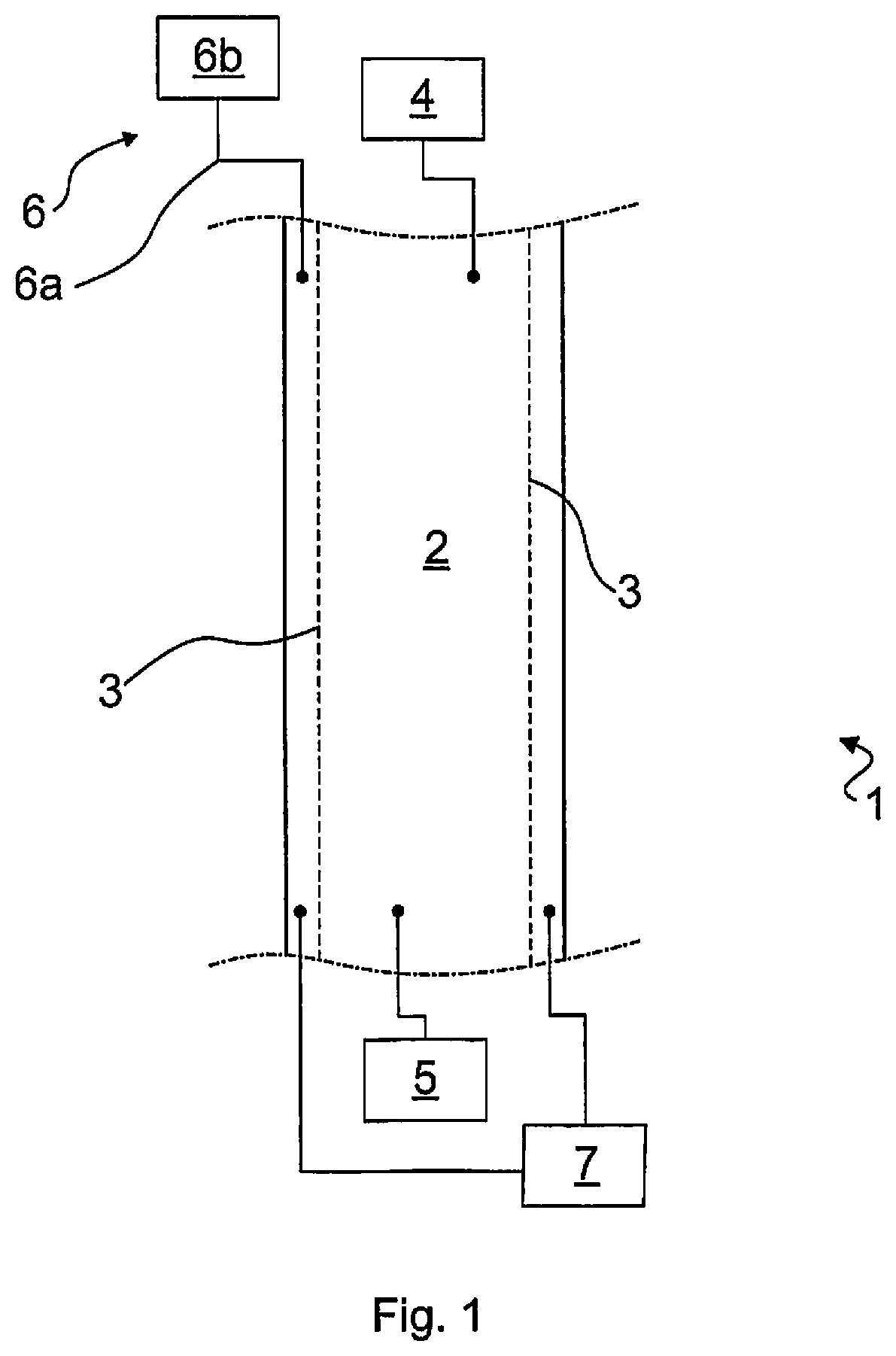

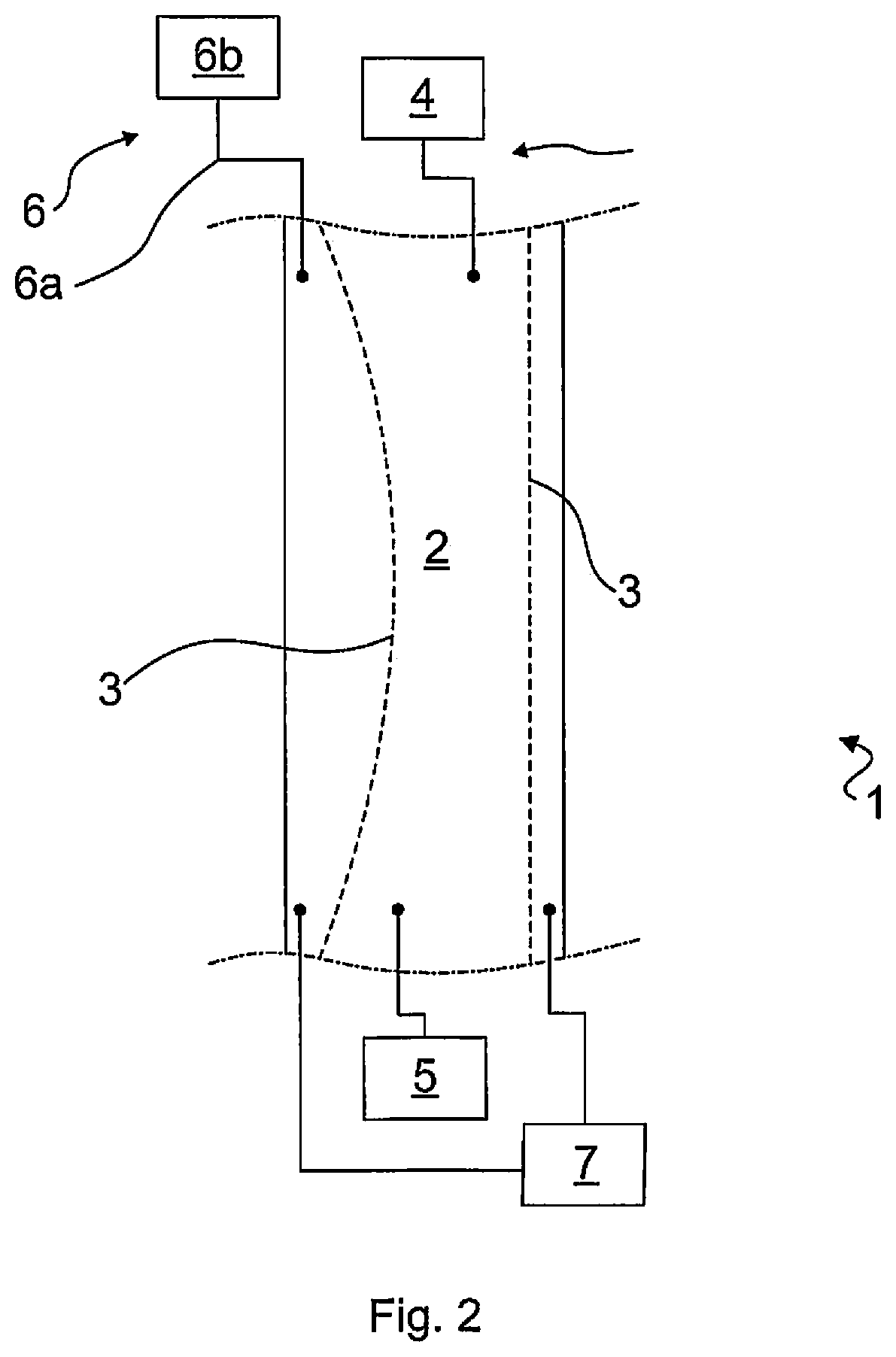

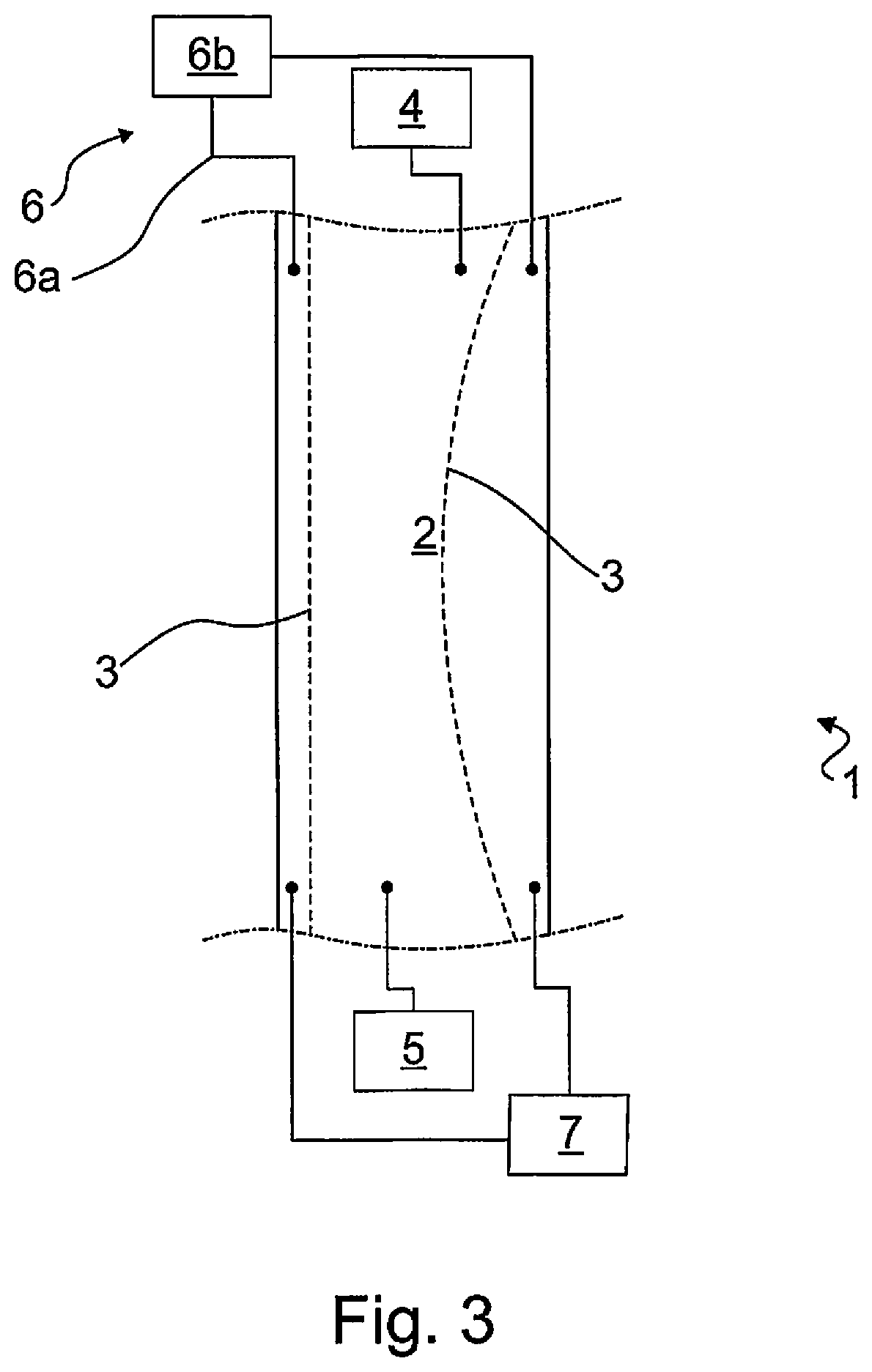

[0015]According to a first aspect of the present disclosure, a method of operating a filter press 1 is provided. In the method, filter material is fed into a filter chamber 2 so as to separate filtrate from solids with a flexible filter medium 3, and to form a filter cake within the filter chamber 2 between at least two sides of said filter medium. As the filter medium 3 has at least two sides, filtrate may suitably be received through said at least sides during feeding of filter material Filtrate is received from the filter chamber 2 through the filter medium 3. That is, filtrate is collected, drained and passed further on. Thereafter, the filter cake formed within the filter chamber 2 is discharge therefrom.

[0016]The method further comprises, prior to discharging the filter cake, applying compression on the filter cake formed within the filter chamber 2. This is done by providing compression gas directly on a side of the filter medium 3 exterior to the filter chamber 2, so as to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| feed pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com