Melt-Formed Inorganic Fibres

a technology of inorganic fibres and melt-formed fibres, which is applied in the field of aluminium-based inorganic fibres, can solve the problems of low biopersistence, significantly more complex, and high cost of the solubility of the gel process fibr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 3

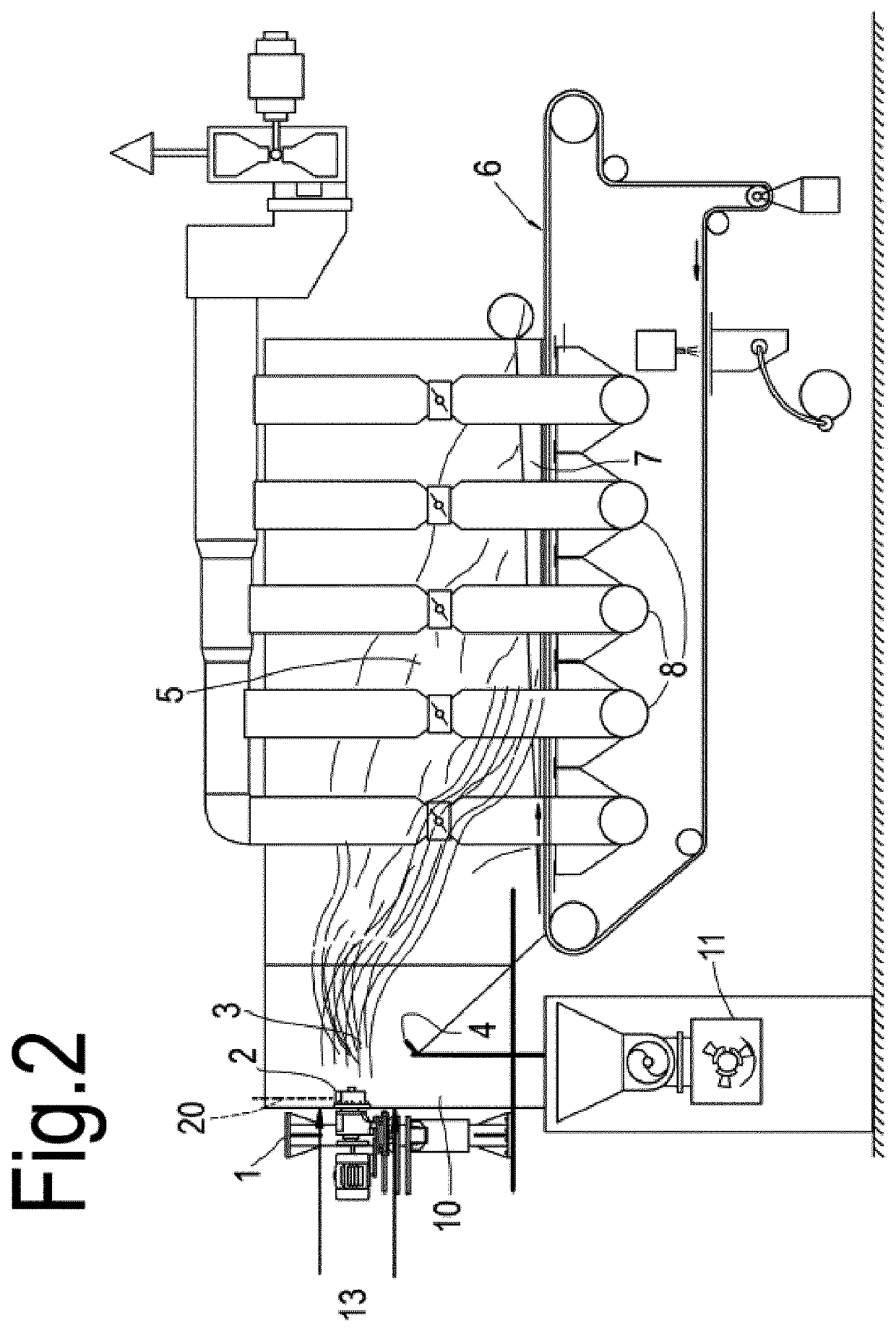

[0147]An aluminosilicate fibre was trialled on spinning apparatus as shown in FIG. 2 using pairs of 20 cm (8″) rotors, and the rotor speed increased stepwise from 9000 / 9500 rpm (one rotor at 9000, the other at 9500 rpm) through to both rotors running at 15,000 RPM. Fibre diameter and shot content were measured and the results and fibre composition are set out in FIG. 10.

[0148]With increasing rotor speed both fibre diameter and shot content decreased to provide, at higher speeds, fibres having fibre diameters similar to blown RCF, but shot content similar to or significantly less than spun RCF.

[0149]In light of the results of Example 3 the applicants have compared:[0150]aluminosilicate materials made with the presently claimed apparatus using the rotor configuration of Example 3 and high rotor speeds (both rotors at 14,500 rpm); with, materials made using the presently claimed apparatus using lower rotor speeds[0151]commercially available materials.

example 4

[0152]A “standard” spun refractory ceramic fibre has a typical composition in weight percent:[0153]Alumina 46-48%[0154]Silica 52-54%

and is exemplified by Cerablanket™ (a trademark of Morgan Advanced Materials plc). Such a material has a shot content >45 μm of about 50%.

[0155]A material of the same composition made using the high rotor speeds (both rotors at 14,500 rpm) has a shot content >45 μm of 43-46%.

[0156]Comparative results for thermal conductivity for a 128 kg / m3 blanket measured by ASTM-C201 expressed in W / mK are shown in Table 7.

TABLE 7Thermal Conductivity (W / m · K)TemperatureExampleMorgan Cerablanket ™%(° C.)4-14500 rpmRCF (data sheet)difference2000.060.06 0%4000.080.120%6000.120.1520%8000.170.215%10000.230.2715%

example 5

[0157]Blown fibres tend to be finer than spun fibres, and to hence provide lower thermal conductivity. However blown fibres tend to be shorter than spun fibres and blankets are difficult to make from blown fibres. Blown fibres also tend to have more shot than spun fibres. Typically blown RCF has a shot content >45 μm of above 50%, and above a spun fibre of like composition.

[0158]High alumina (HA) RCF fibre is known for meeting higher temperature applications than standard RCF fibre and is normally blown, as it has proven difficult in the past to spin or make into blanket.

[0159]HA fibres have typical compositions in weight percent:

Alumina50-53%Silica47-50%

[0160]Comparative results for thermal conductivity for a 128 kg / m3 blanket measured by ASTM-C201 expressed in W / mK are shown in Table 8, which compares:[0161]A. a spun HA fibre with composition based on

Alumina50-52%Silica48-50%[0162]made using the high rotor speeds (both rotors at 14,500 rpm) having a shot content >45 μm of 43-46%.[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| arithmetic mean diameter | aaaaa | aaaaa |

| arithmetic mean diameter | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com