Subsea Field Architecture

a technology of subsea field and submerged structure, which is applied in the direction of insulation, wellbore/well accessories, construction, etc., can solve the problems of reducing the flow of well fluid to the offsite production and/or processing facility. , to achieve the effect of preventing the formation of hydrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

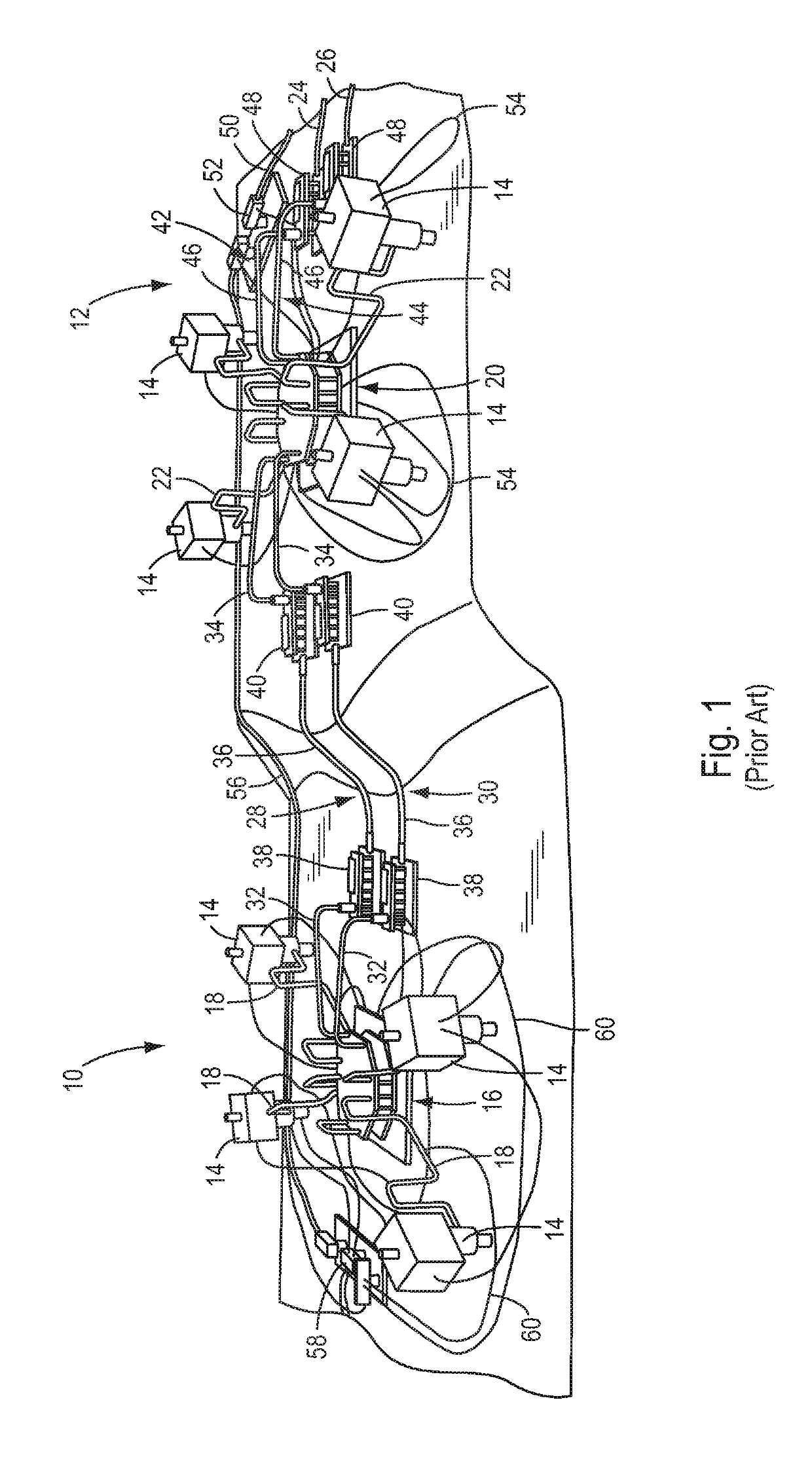

[0028]As background for the present disclosure, an example of a prior art subsea oil or gas field will be described with reference to FIG. 1. The prior art oil or gas field includes a plurality of subsea wells which are arranged into two sub-fields 10 and 12. As shown in FIG. 1, for example, each sub-field 10, 12 has four subsea wells. Each well comprises a wellhead on which is mounted a corresponding subsea christmas tree 14. Each tree 14 in the first sub-field 10 is connected to a first manifold 16 by a corresponding flowline jumper 18. Similarly, each tree 14 in the second sub-field 12 is connected to a second manifold 20 by a corresponding flowline jumper 22. The flowline jumpers 18, 22 are rigid pipes which must each be specifically designed to span the exact distance between a respective connection hub on the tree 14 and a corresponding connection hub on the manifold 16, 20.

[0029]The well fluids produced through the trees 14 are routed through the first and second manifolds 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com