Mitigating hydrate formation during a shutdown of a deep water fpso

a technology of deep water and hydrate formation, which is applied in the direction of fluid removal, earthwork drilling and mining, borehole/well accessories, etc., can solve the problems of affecting the flow of production, and hydrate formation may tend to form, so as to prevent freezing, reduce complexity, and prevent the effect of hydrate formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

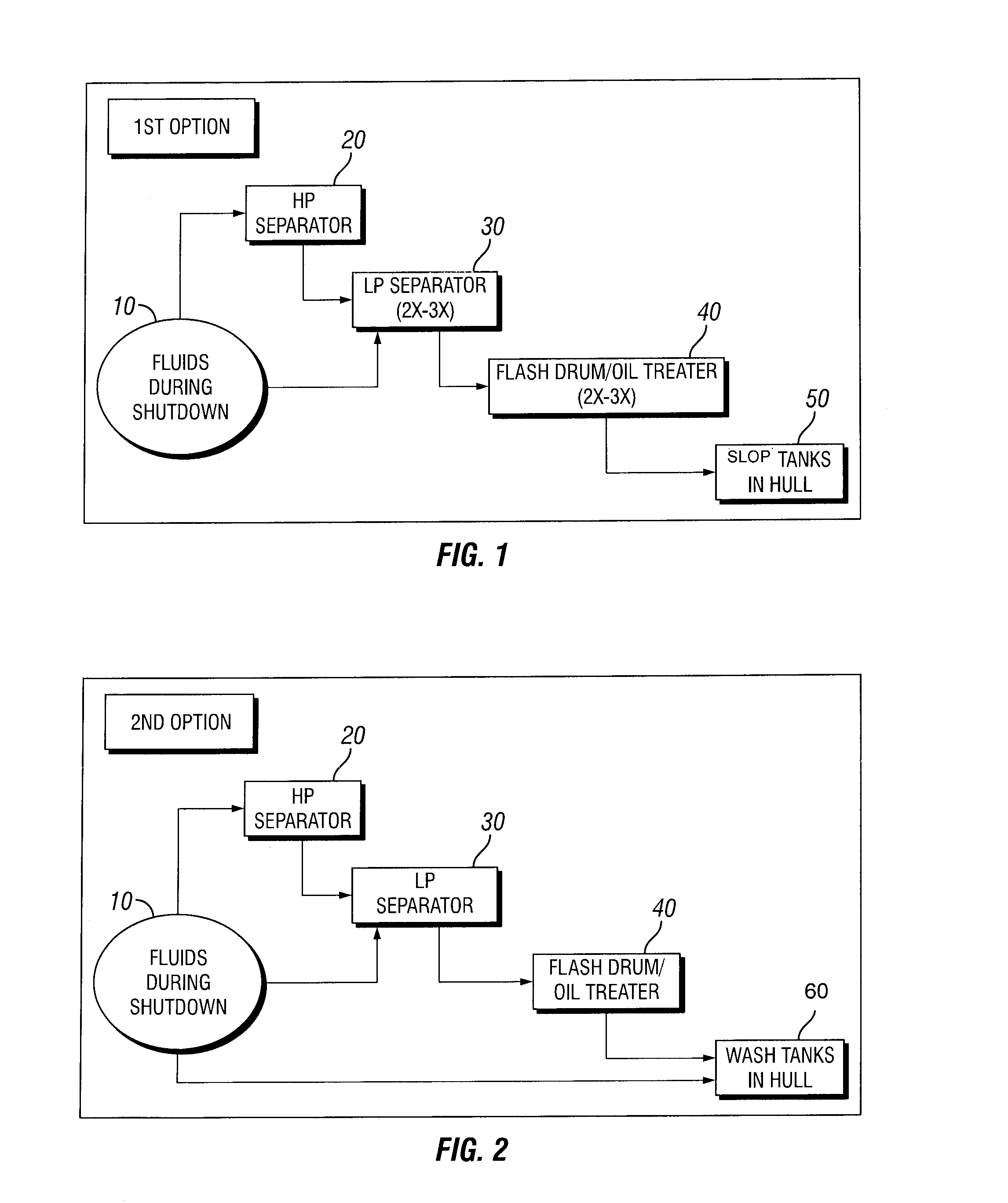

[0009]The present invention pertains in one embodiment to a method for managing hydrates in a subsea production system during a shutdown. The method comprises first producing hydrocarbon fluids from one or more remote subsea production wells through a production flow loop. By remote subsea production well is meant a subsea well that has a long distance tie-back (LDTB) to the offshore production facility. Such remote wells may often be more than 5000 feet deep and / or more than 20 miles from an offshore production facility, e.g., one comprising one or more FPSO units, and thus the configuration may be referred to as a long distance tie-back. In some example embodiments, the remote wells may be more than 40 miles from an offshore production facility.

[0010]The initial production of hydrocarbon fluids may be typical to what is ordinarily done in that hydrocarbon fluids from one, two, three, four, or even more remote wells flow through a production flow loop to, for example, an FPSO unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com