Compressor

a compressor and impeller technology, applied in the field of compressors, can solve the problems of unstable flow of compressed air out of the compressor impeller into the fixed diffuser, and decrease in supercharging efficiency,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

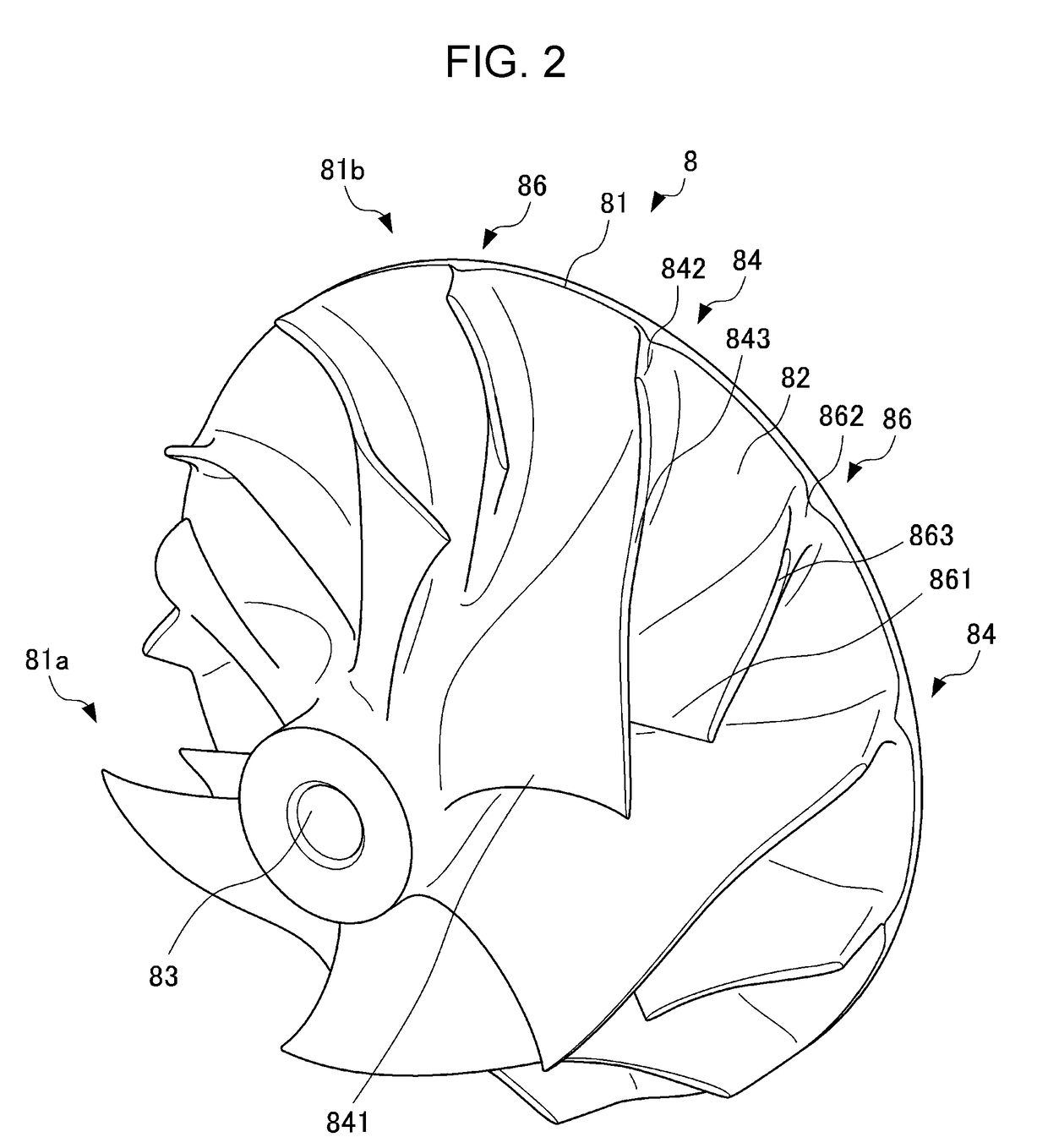

[0020]The embodiment(s) will now be described with reference to the accompanying drawings, wherein like reference numerals designate corresponding or identical elements throughout the various drawings.

[0021]Hereinafter, an exemplary embodiment of the present disclosure will be described with reference to the drawings.

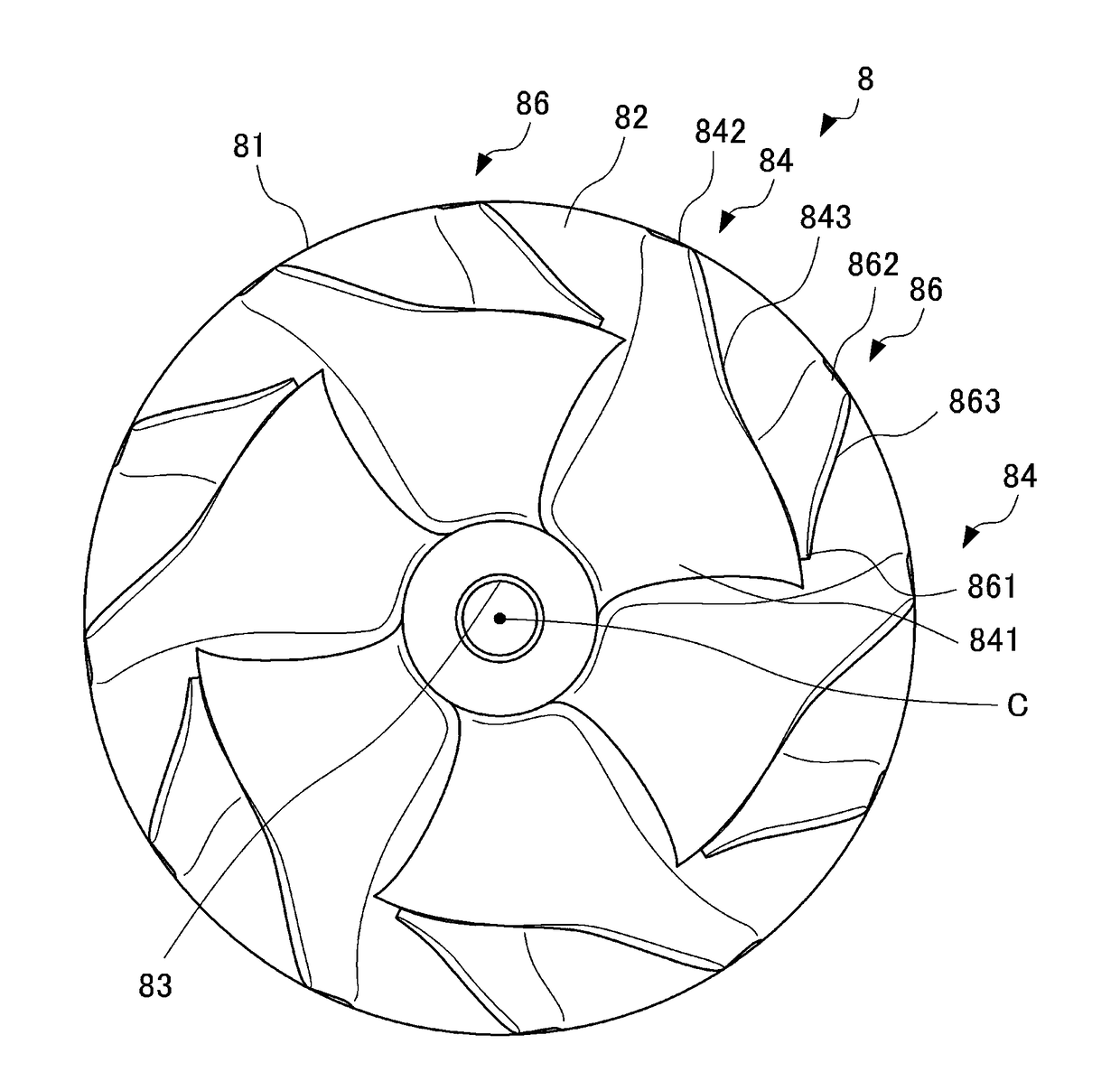

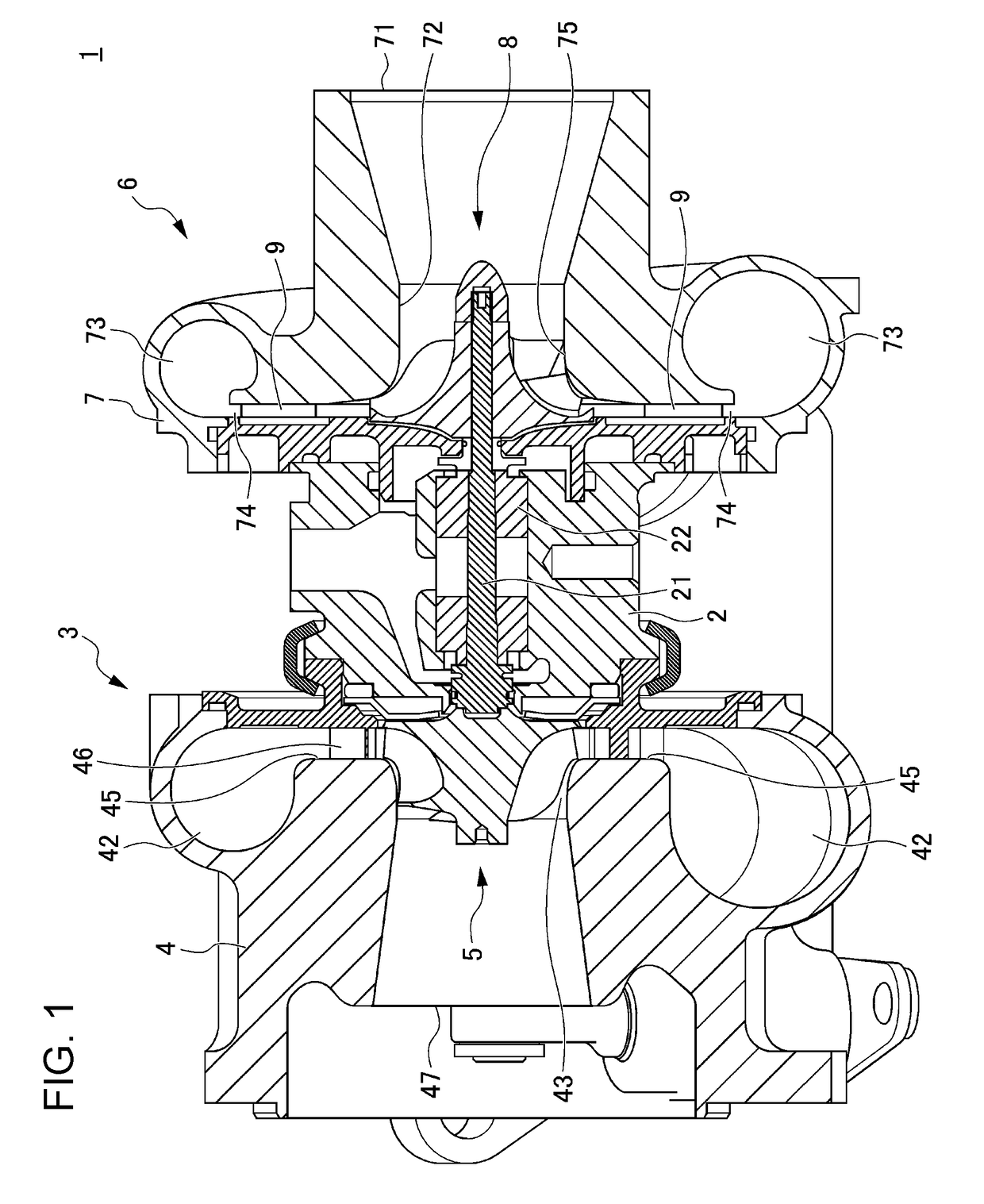

[0022]FIG. 1 is a cross-sectional view illustrating a configuration of a supercharger 1 using a compressor according to the present exemplary embodiment.

[0023]The supercharger 1 includes a turbine 3 mounted on one end of the bearing housing 2, and a compressor 6 mounted on the other end of the bearing housing 2. The bearing housing 2 includes a rod-shaped rotating shaft 21 extending between the turbine 3 and compressor 6, and a bearing 22 that rotatably supports the rotating shaft 21.

[0024]The turbine 3 includes a turbine housing 4 constituting a portion of an exhaust passage of an internal-combustion engine (not shown), and a turbine impeller 5 provided inside the turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com