Vacuum heat insulating body, and heat insulating container and heat insulating wall employing same

a vacuum heat insulating and body technology, applied in the field of vacuum heat insulating body, and a heat insulating container and a heat insulating wall employing the same, can solve the problems of inability to apply heat insulating material, limitation of improving the ratio of the area which can be covered with vacuum heat insulating material, and general complicated shape of the heat insulating space of the heat insulating case body. achieve small ventilation resistance, reduce the thickness, and significant ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first exemplary embodiment

[0066]First, a first exemplary embodiment of the present invention will be described. In the present exemplary embodiment, description will be given with reference to an example of a case where a heat insulating case body itself in refrigerator 1 is configured with a vacuum heat insulating body. However, the exemplary embodiment is merely an example, and the configuration of the vacuum heat insulating body of the present exemplary embodiment can also be used in a part of a door.

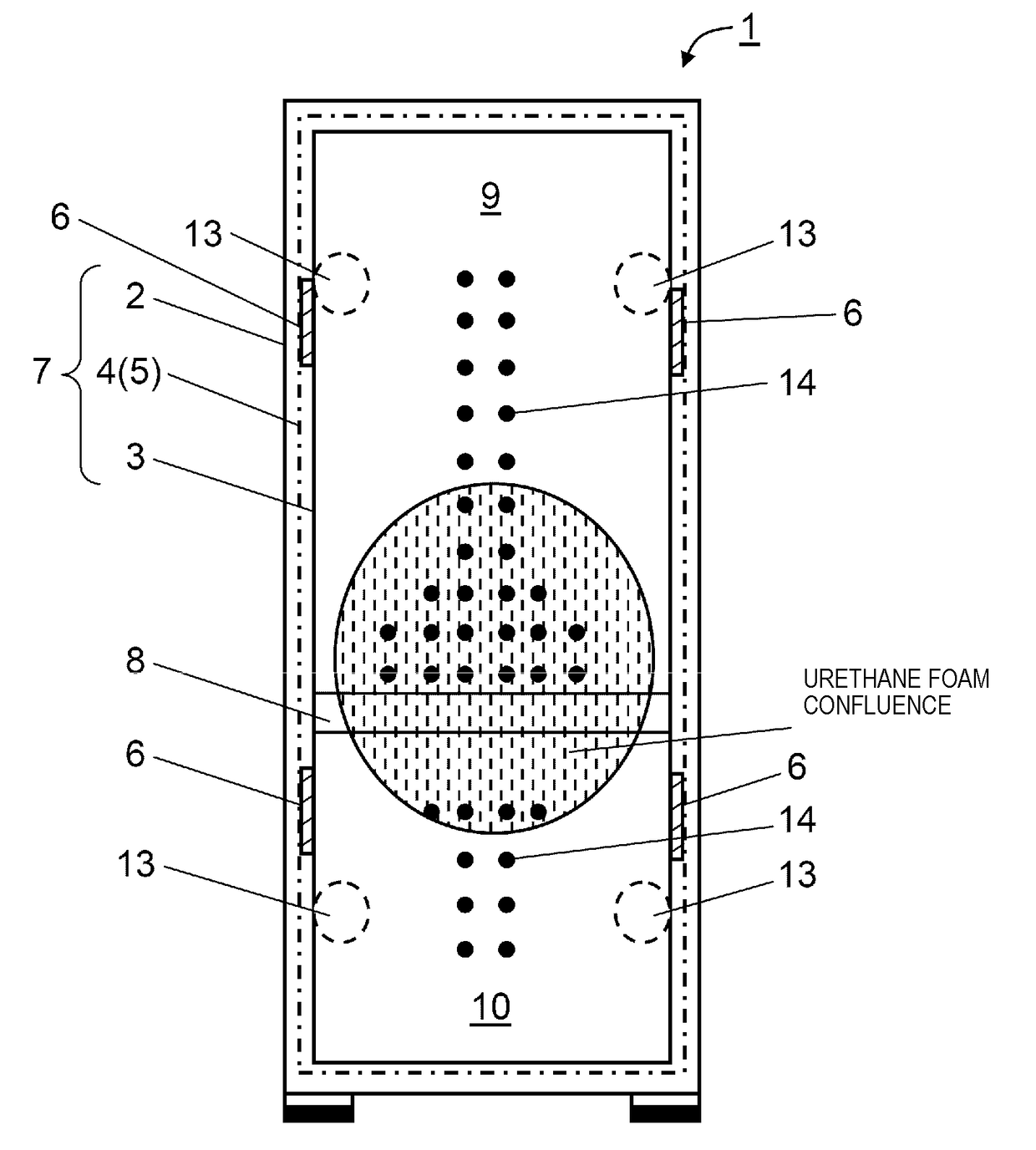

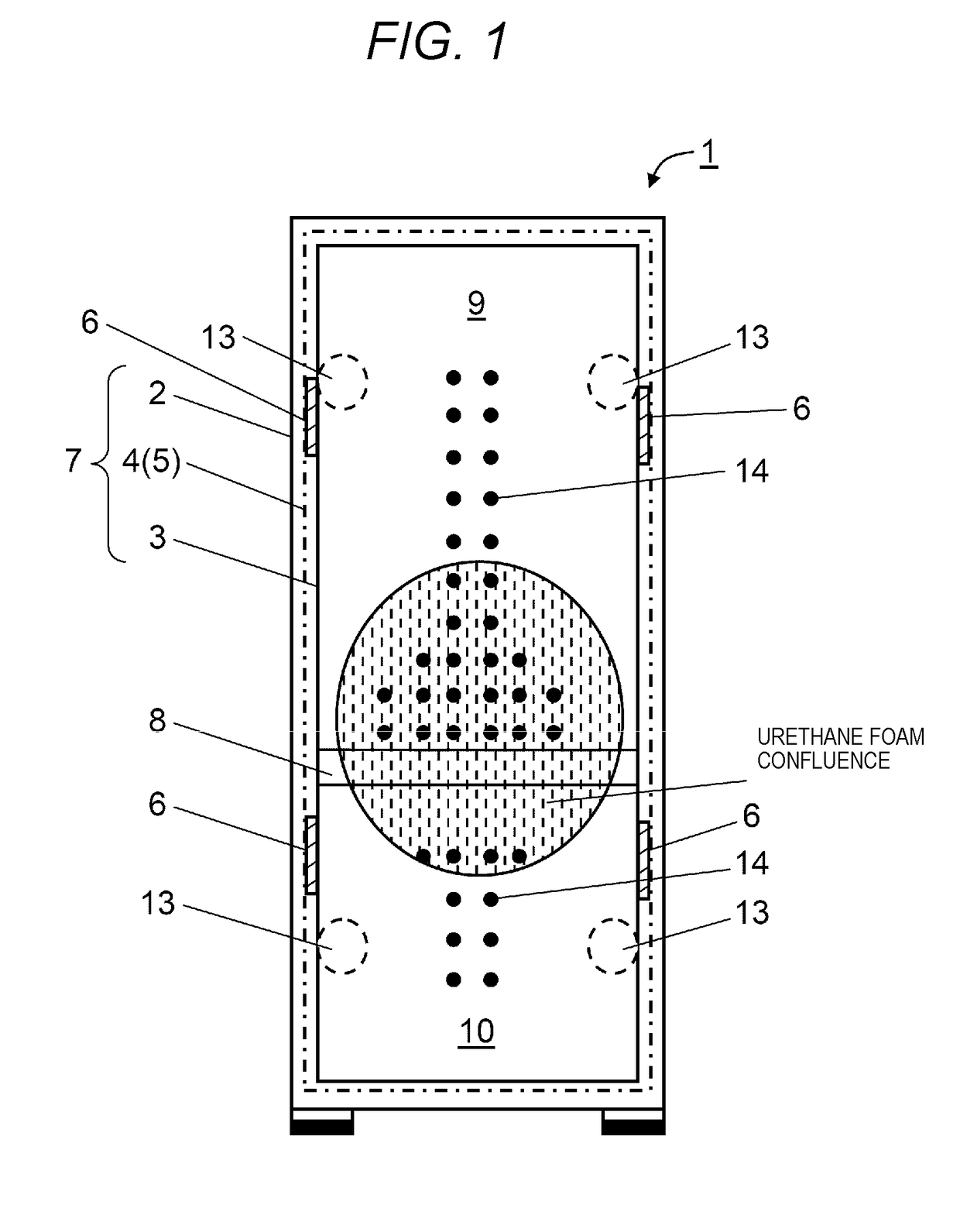

[0067]FIG. 1 is a front view of vacuum heat insulating case body 7 of refrigerator 1 employing the vacuum heat insulating body in the first exemplary embodiment of the present invention, and FIG. 2 is a cross-sectional view illustrating a configuration of a portion of a wall surface of vacuum heat insulating case body 7 thereof.

[0068][Configuration of Refrigerator]

[0069]First, the configuration of refrigerator 1 of the present exemplary embodiment will be described.

[0070]As illustrated in FIG. 1, refrigerator...

second exemplary embodiment

[0119]Subsequently, a second exemplary embodiment of the present invention will be described.

[0120]In the present exemplary embodiment, description will be given regarding an example of employing the vacuum heat insulating body in the heat insulating structure body of an LNG inboard tank in an LNG transport tanker.

[0121]FIG. 7 is a view illustrating a schematic cross-sectional configuration of a membrane-type LNG transport tanker including an inboard tank employing the vacuum heat insulating body, in the second exemplary embodiment of the present invention. FIG. 8 is a view describing the two-layer structure of the inner surface of the inboard tank of the same LNG transport tanker, and FIG. 8 illustrates a schematic prospective view and a partially enlarged cross-sectional view thereof. FIG. 9 is an enlarged cross-sectional view of the vacuum heat insulating body employed in the heat insulating structure body of the same inboard tank.

[0122]FIG. 7 illustrates heat insulating containe...

modification examples

Other Modification Examples

[0132]As described above, the forms illustrated in the first exemplary embodiment and the second exemplary embodiment provide a high-quality vacuum heat insulating body having high heat insulating performance at a low price. However, the present invention is not limited to these examples, and various changes can be made within the range in which the object of the present invention is achieved.

[0133]For example, in each of the exemplary embodiments described above, vacuum heat insulating case body 7 of refrigerator 1 and vacuum heat insulating body 29 of heat insulating container 21 for an LNG hull tank are described as examples. However, the vacuum heat insulating body, and the configuration and the shape of the heat insulating structure body in which the vacuum heat insulating body is applied are not limited thereto. In other words, instead of the shape of a container, the heat insulating structure body may be employed as a heat insulating wall or the lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com