Gas turbine fan fairing platform and method of fairing a root leading edge of a fan blade of a gas turbine engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

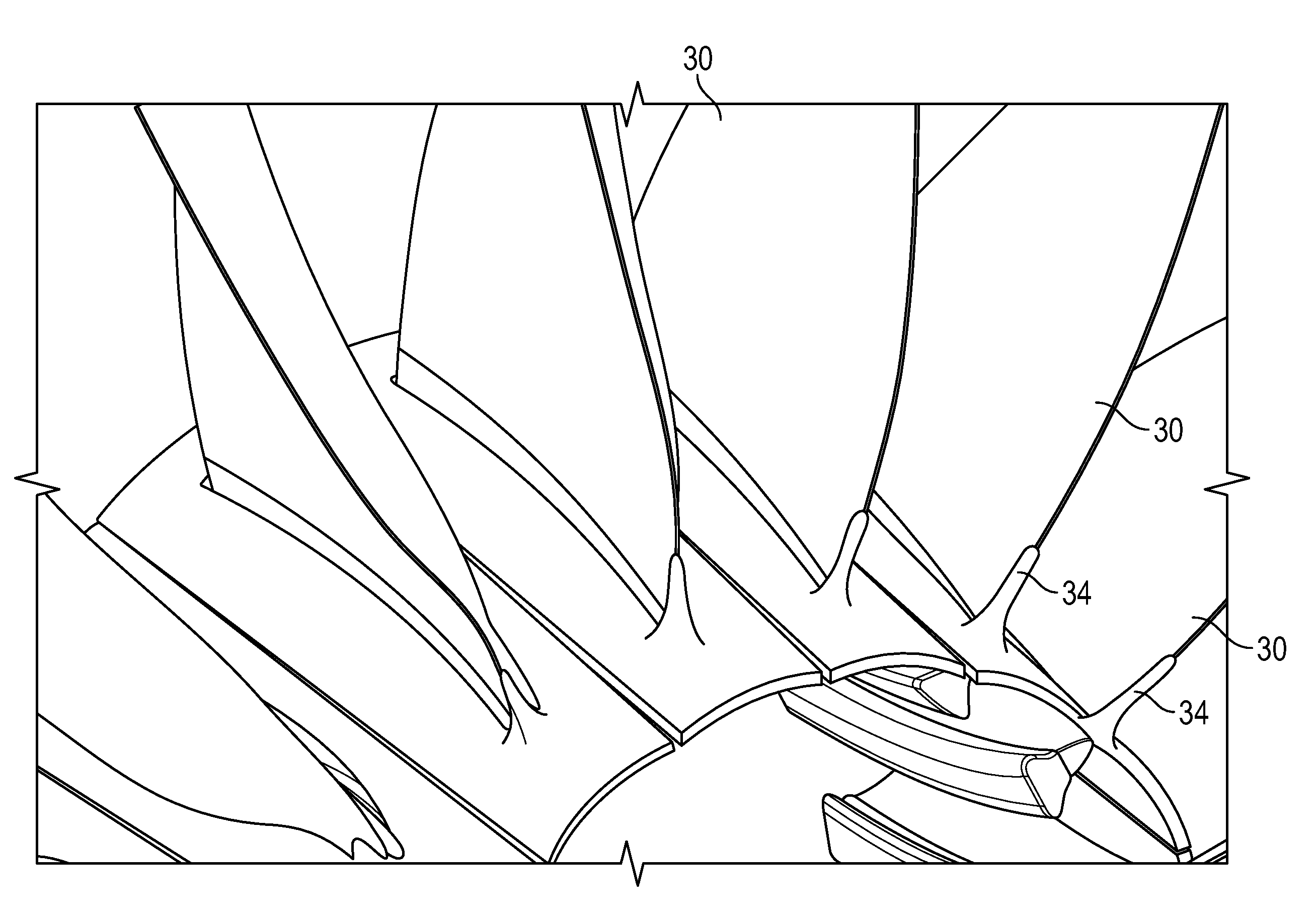

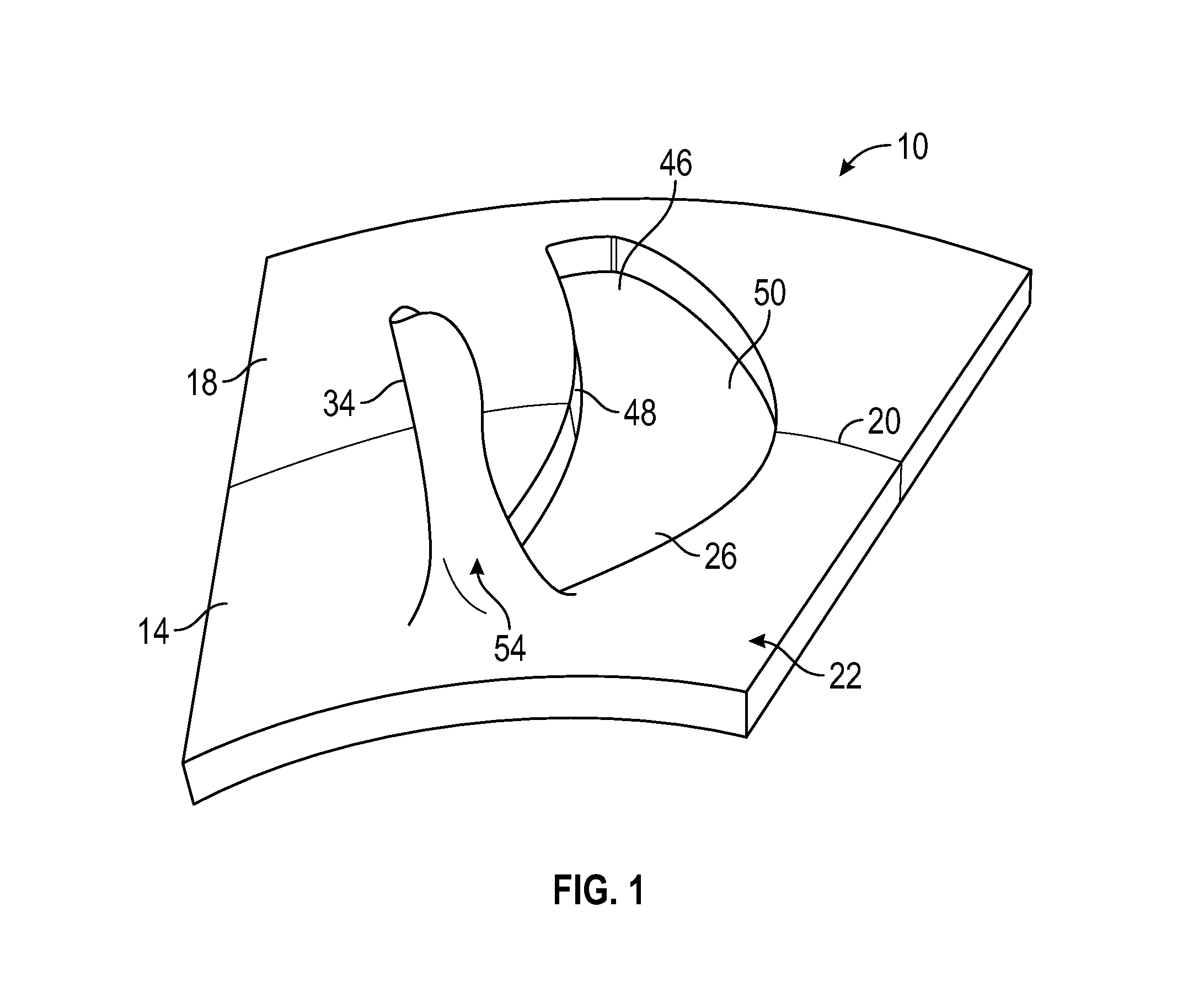

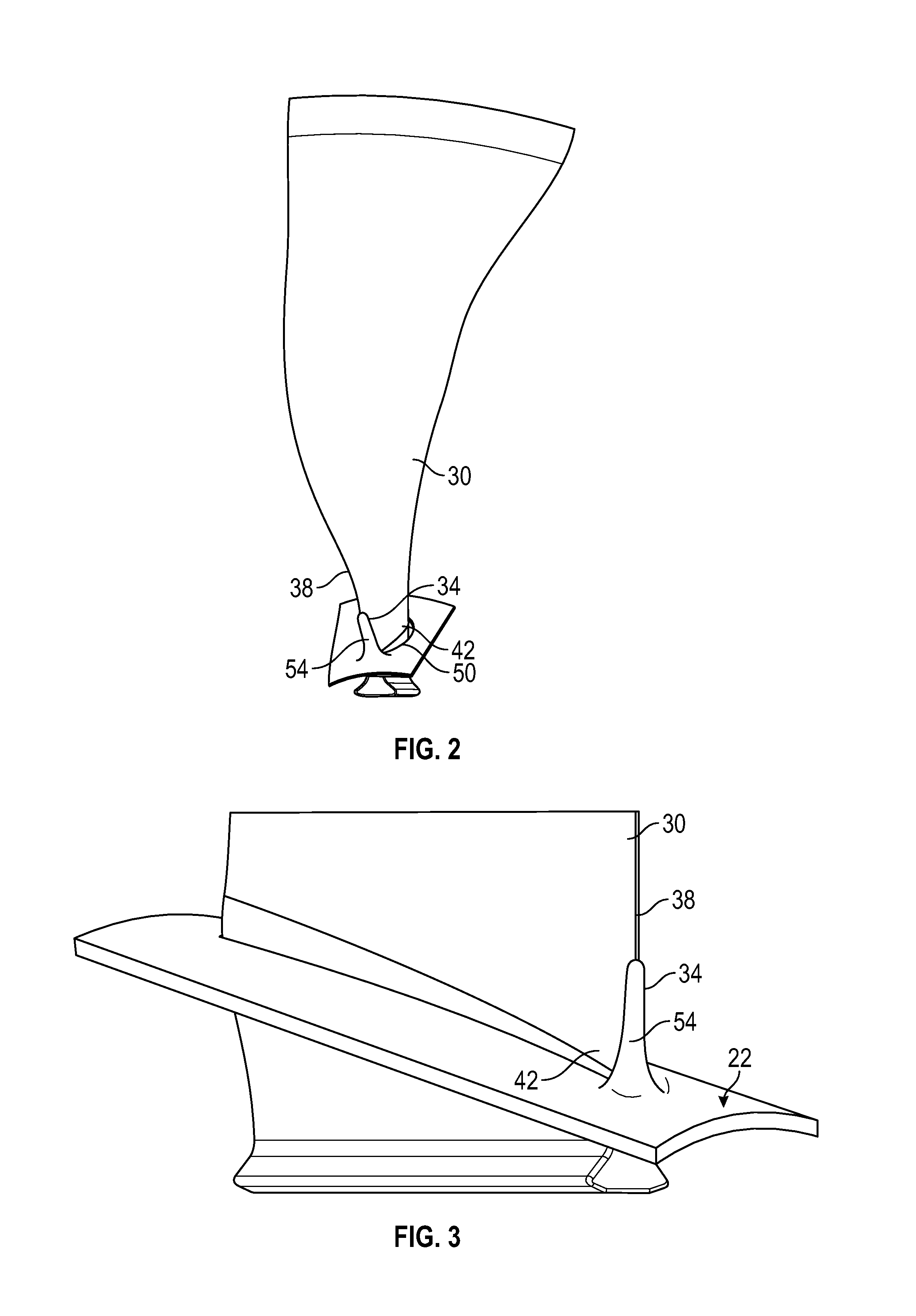

[0022]Referring to FIGS. 1-4, an embodiment of a gas turbine fan fairing platform disclosed herein is illustrated generally at 10. The platform 10 includes at least one body 14, 18, with two of the bodies being shown in the illustrated embodiment, although any practical number of the bodies could be employed. A seam 20 shows where the two bodies 14, 18 are come together. Other embodiments can have one or more seams oriented in other directions depending upon the number of bodies employed and the direction in which they come together. At least one of the bodies 14 has an opening 26 receptive to a blade 30 (not shown in FIG. 1) and defines a surface 22. A protrusion 34 extends outward from the surface 22 in a direction that positions the protrusion 34 proximate a leading edge 38 of the blade 30 near a root 42 of the blade 30.

[0023]The two bodies 14, 18 of the platform 10 are attachable such that the opening 26 in the body 14 and an opening 46 in the body 18 form a single larger openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com