Reflective mask cleaning apparatus and reflective mask cleaning method

a technology of reflective masks and cleaning methods, which is applied in the direction of cleaning processes and apparatus, photomechanical treatment, instruments, etc., can solve the problems of ruthenium oxide formation in the exposed portion, decrease in reflectance, and inability to clean the exposed portion, etc., to achieve the effect of suppressing the degradation of optical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

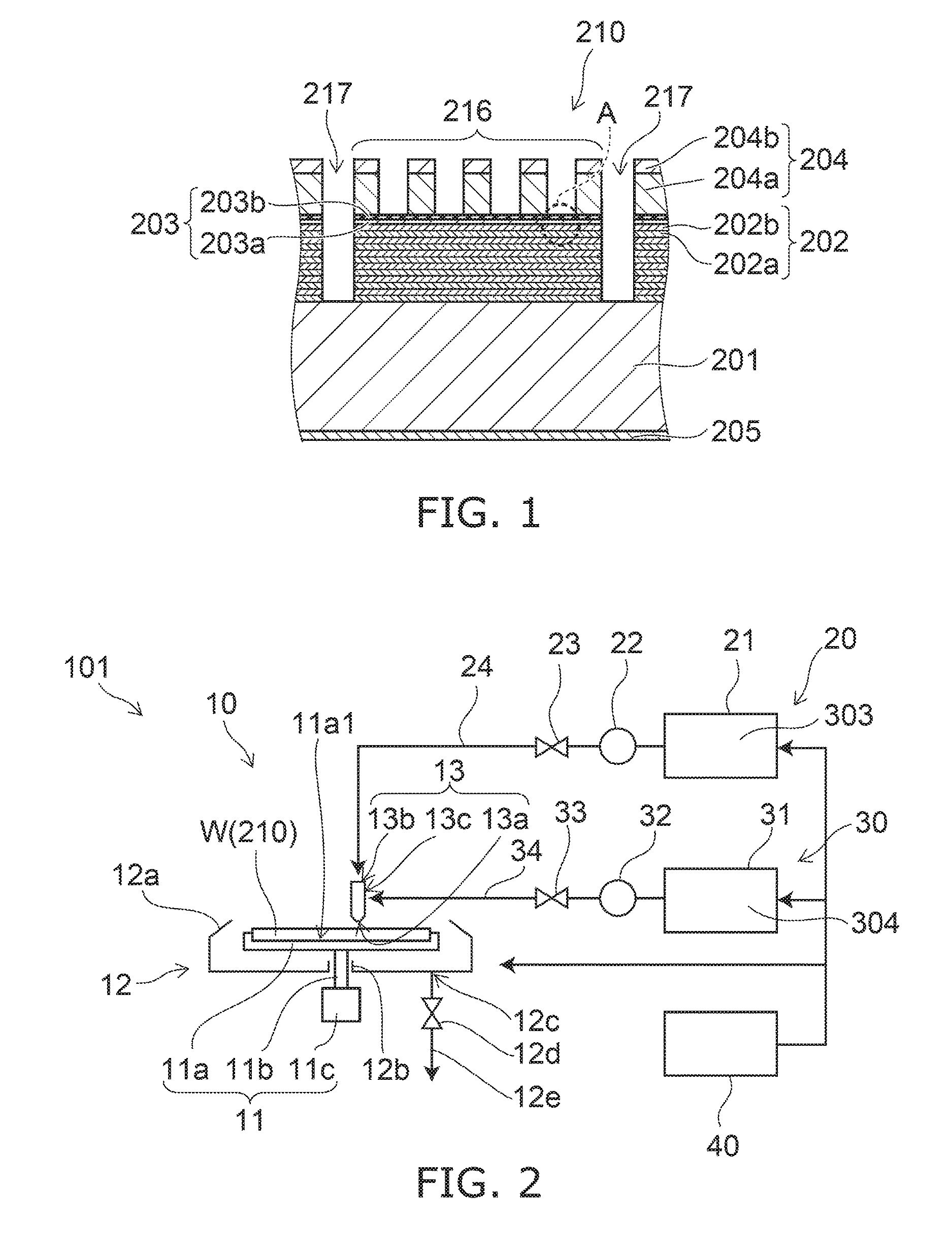

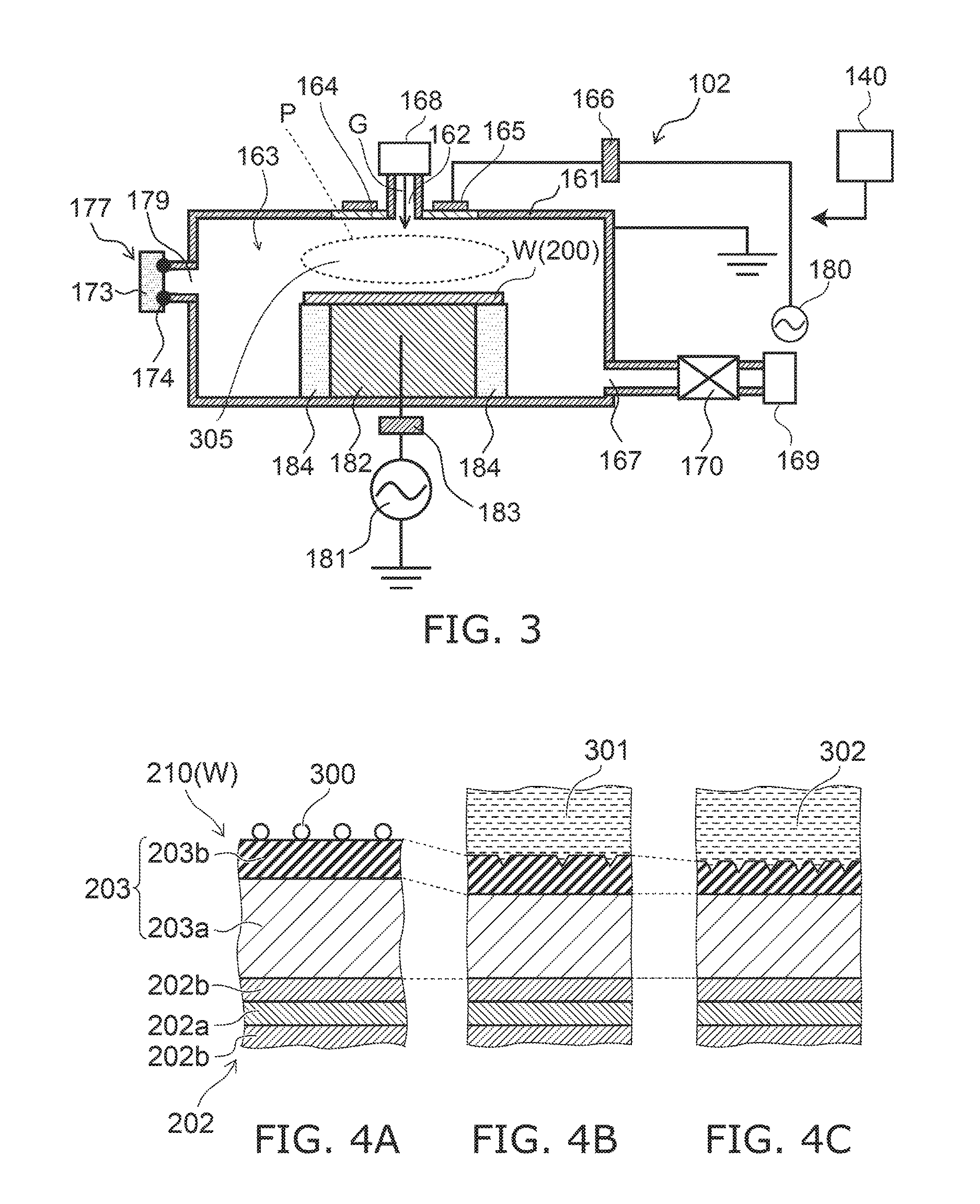

[0025]Embodiments will now be illustrated with reference to the drawings. In the drawings, similar components are labeled with like reference numerals, and the detailed description thereof is omitted appropriately.

[0026]The to-be-cleaned object W can be configured so that a layer containing an oxidizable material is exposed.

[0027]The to-be-cleaned object W can be e.g. a reflective mask including a ruthenium-containing capping layer or a substrate including a ruthenium-containing capping layer (a substrate under the process for manufacturing a reflective mask).

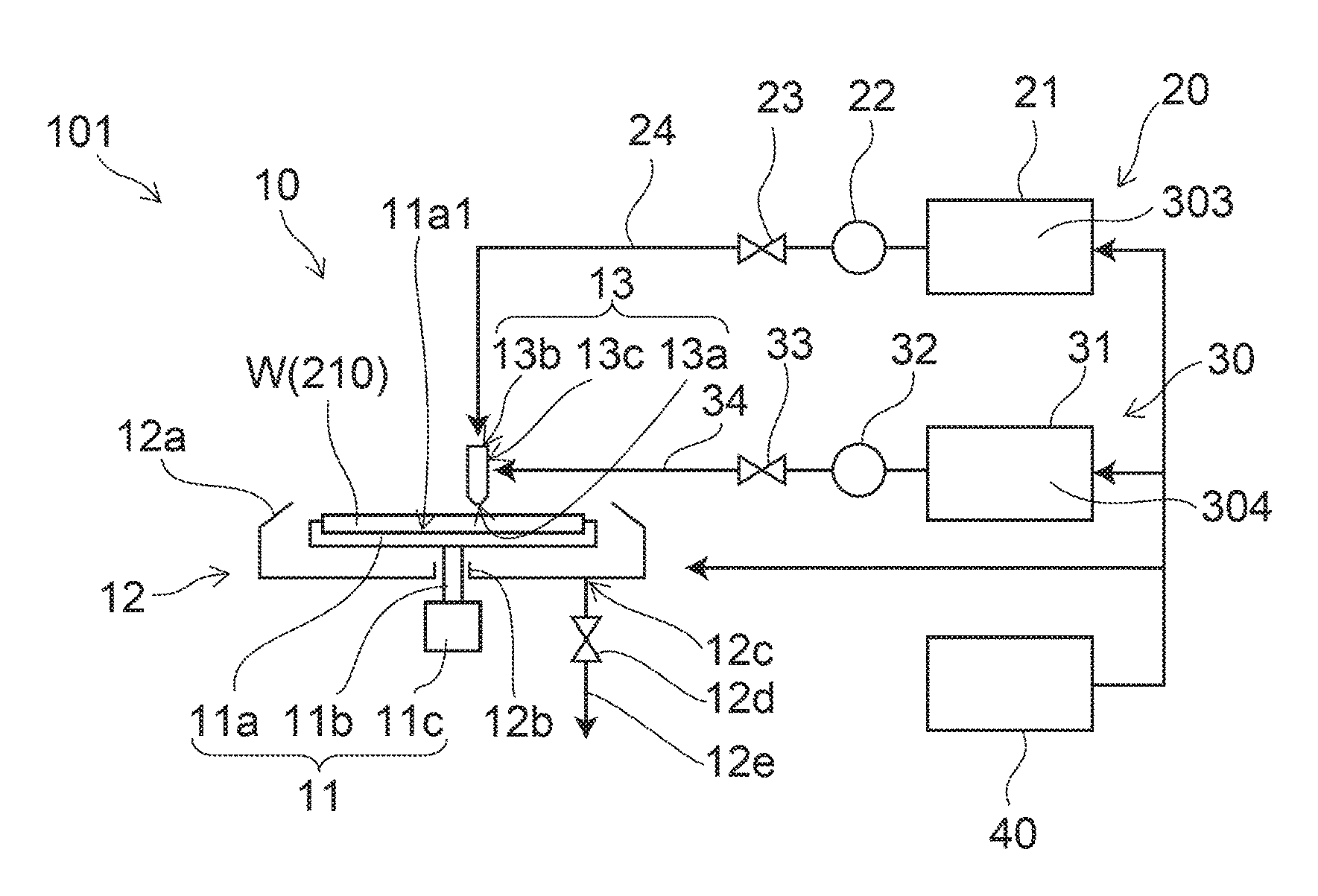

[0028]FIG. 1 is a schematic sectional view for illustrating a reflective mask 210 serving as a to-be-cleaned object W.

[0029]As shown in FIG. 1, on one major surface of a substrate 201, a reflection layer 202, a capping layer 203, and an absorption layer 204 are stacked in this order.

[0030]A conductive layer 205 is formed on the other major surface of the substrate 201.

[0031]The substrate 201 is formed from e.g. a low thermal ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com