Motor with heat dissipation structure

a heat dissipation structure and motor technology, applied in the field of motors, can solve the problems of difficult accumulation of heat in the housing, and achieve the effect of increasing the service life and performance of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

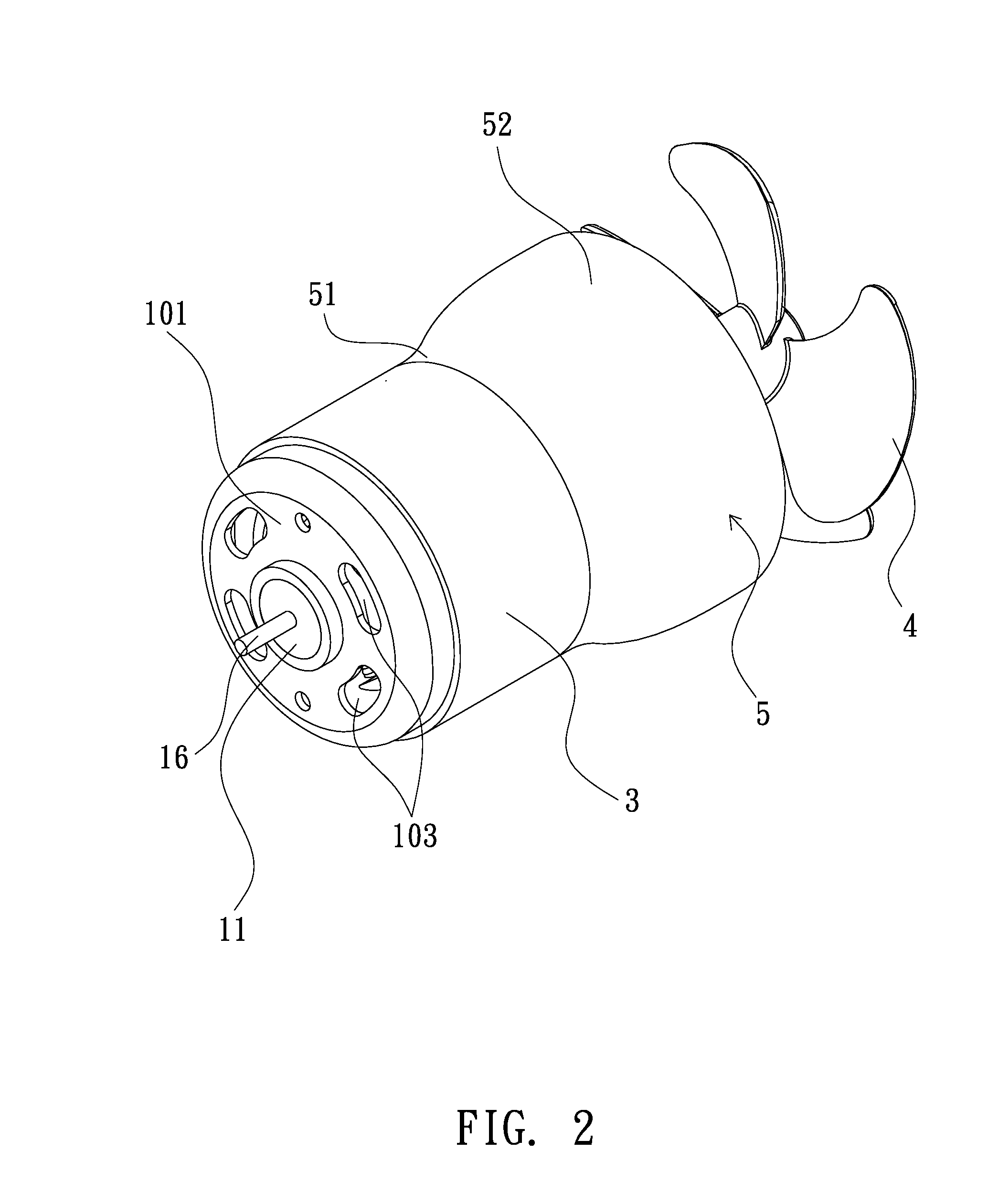

[0014]Since motors are commonly used devices, the principles of a motor's operation are not illustrated in the following paragraphs. However, basic elements of a motor will be described in this specification. Referring to FIGS. 1 through 7, a motor according to one embodiment of the present invention is shown, which includes a cylindrical housing 1, in which a rotor assembly and two opposite magnets 12 are provided. The rotor assembly includes a rotating shaft 16, an armature core formed by an iron core 171 wound with enameled wire 172, and a commutator 173. The two opposite magnets 12 are provided at an inner surface of the cylindrical housing 1. The housing 1 has a circumferential wall which terminates at a flat closure wall 101 (a front end of the motor). The flat closure wall 101 is provided with a first bearing 11 at its center and defines a plurality of downstream through holes 103 around the first bearing 11. A first end of the rotating shaft 16 is mounted to the first bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com