Vacuum Air Pump and Glass-Wiping Apparatus

a vacuum air pump and glass-wiping technology, which is applied in the direction of piston pumps, positive displacement liquid engines, machines/engines, etc., can solve the problems of loss of vacuum degree, machine body falling off the glass surface, and larger shaft length, so as to increase the number of piston air pump members, increase the air flow rate of the air pump, and keep the structure simple and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

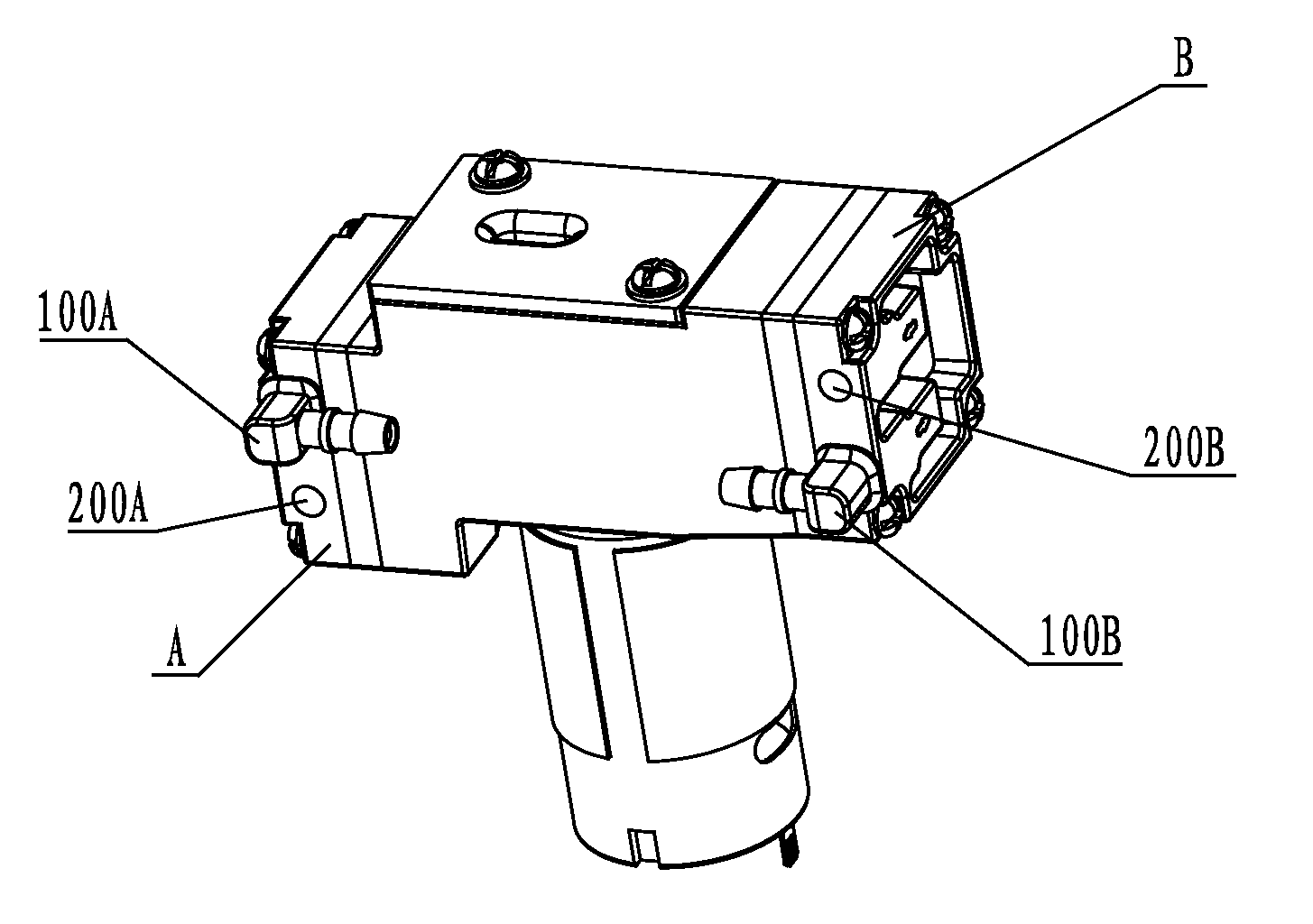

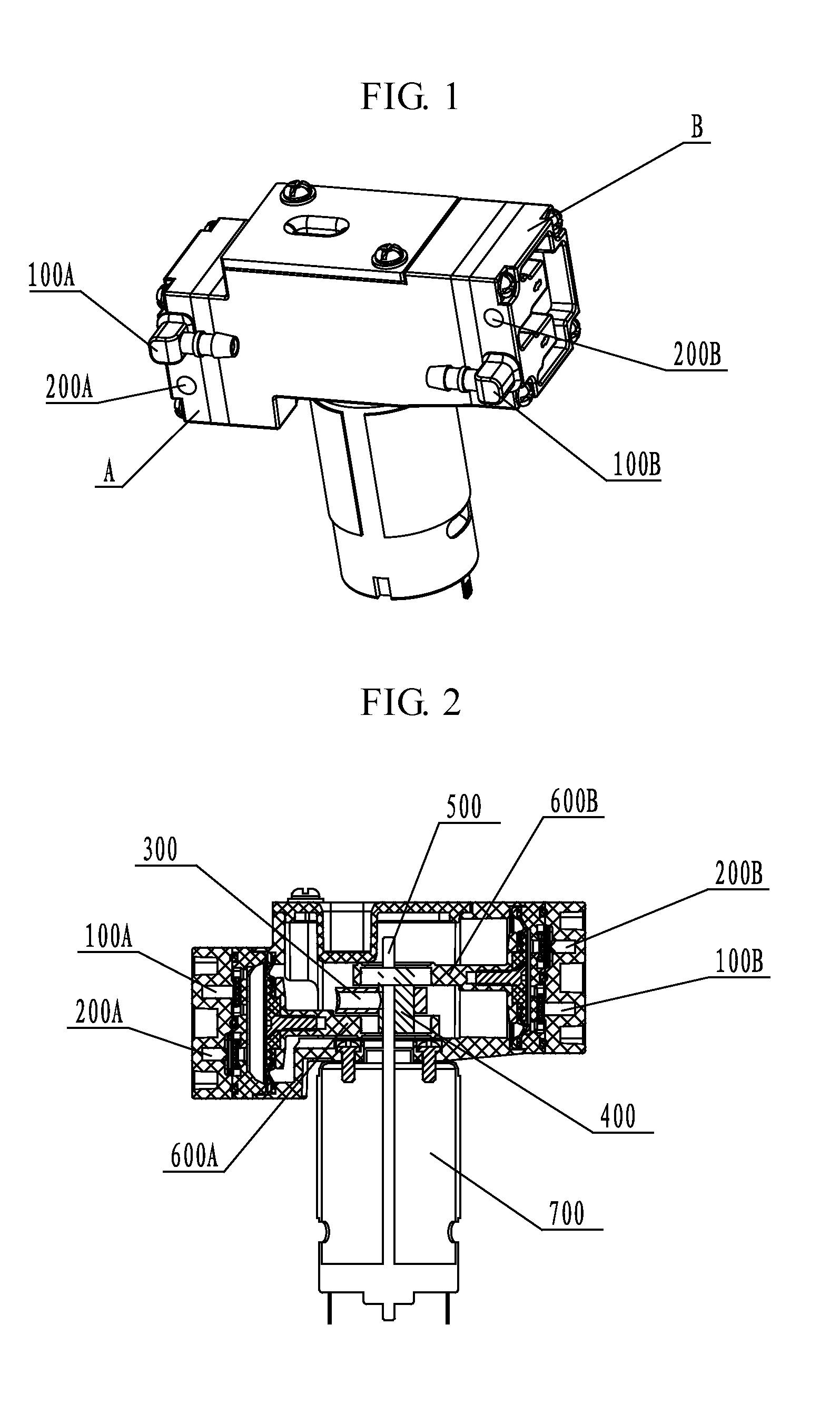

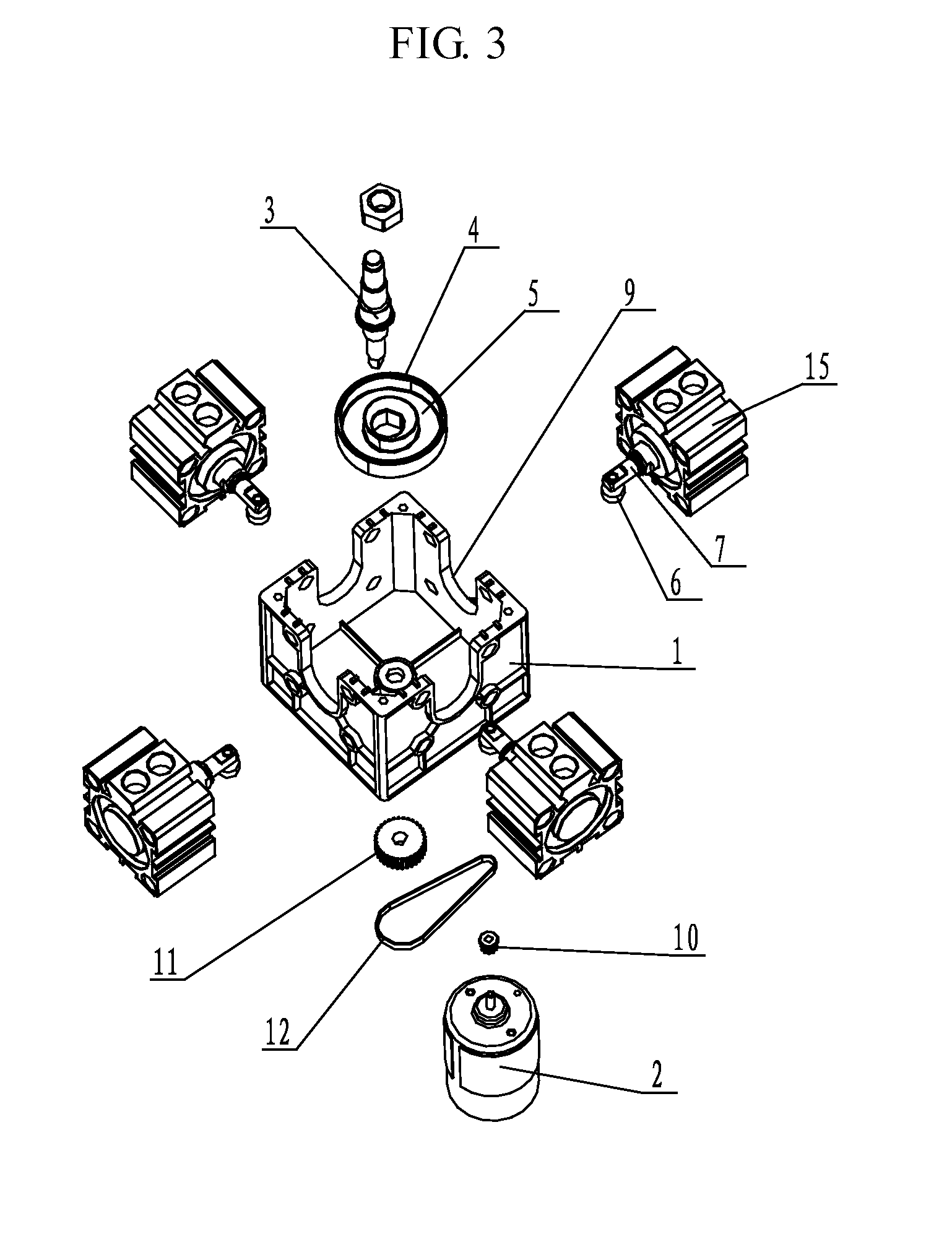

first embodiment

[0025]FIG. 3 is an exploded structural view of the first embodiment of the present invention; FIG. 4 is a sectional view of the first embodiment of the present invention; and FIG. 5 is a structural view of an assembly of the first embodiment of the present invention. As shown in FIGS. 3 to 5, the present invention provides a vacuum air pump comprising a driving motor 2, an air pump body 1 and a piston air pump member 15 provided on the air pump body 1, wherein a rotating shaft 3 is provided in the air pump body 1, the driving motor 2 transmits power to the rotating shaft 3 through a transmission mechanism, and a rotating wheel is fixed on the rotating shaft 3. A diameter-variable annular limitation groove 5 is formed on one side surface of the rotating wheel and may use various shapes, and in the present embodiment, the rotating wheel is an eccentric wheel 4 and thus the diameter-variable annular limitation groove 5 formed on one side surface of the eccentric wheel 4 is round. Four ...

second embodiment

[0029]FIG. 6 is a structural view of the assembly of the second embodiment of the present invention. As shown in FIG. 6, the difference of the present embodiment from the first embodiment is: in the present embodiment, the piston air pump members 15 are provided in three pairs, i.e., six piston air pump members 15 indicated by the numbers 1 to 6 are provided uniformly around the air pump body 1. For the reason that the number of the piston air pump members 15 becomes greater, the outer shape of the air pump body 1 is a cylinder, for ease of arrangement.

[0030]In addition, the transmission mechanism in the present embodiment has a different structure from that of the first embodiment, and comprises a driving gear provided on the shaft of the driving motor 2 and a driven gear provided on the rotating shaft 3, wherein the driving gear and the driven gear are engaged with each other.

[0031]Other technical features of the present embodiment are substantially the same as those of the first ...

third embodiment

[0032]FIG. 7 is a structural view of a diameter-variable annular limitation groove of the third embodiment of the present invention. As shown in FIG. 7, the diameter-variable annular limitation groove in the present embodiment is an irregularly-shaped groove 1000. The piston air pump members 15 are provided around the air pump body in plural pairs, the piston rod 7 of each of the piston air pump members 15 is provided with a rolling element at the end, the rolling element is embedded in the irregularly-shaped groove 1000, the rotating shaft drives the rotating wheel to rotate, and the rolling element rolls within the irregularly-shaped groove 1000 in the circumferential direction of the rotating shaft to thereby drive the piston rod 7 to make a reciprocating movement depending on the size change in radius of the irregularly-shaped groove 1000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com