Pump including a shield for protecting a pump wheel against a coolant leak along the hub of the wheel

a technology for pump wheels and shields, which is applied in the direction of liquid fuel engines, greenhouse gas reduction, nuclear elements, etc., can solve the problems of deterioration of shafts and pump wheels, still observed traces of contact wear on the shaft and the pump wheel, etc., and achieve the effect of reducing the maintenance cost of the primary pump and minimizing contact wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

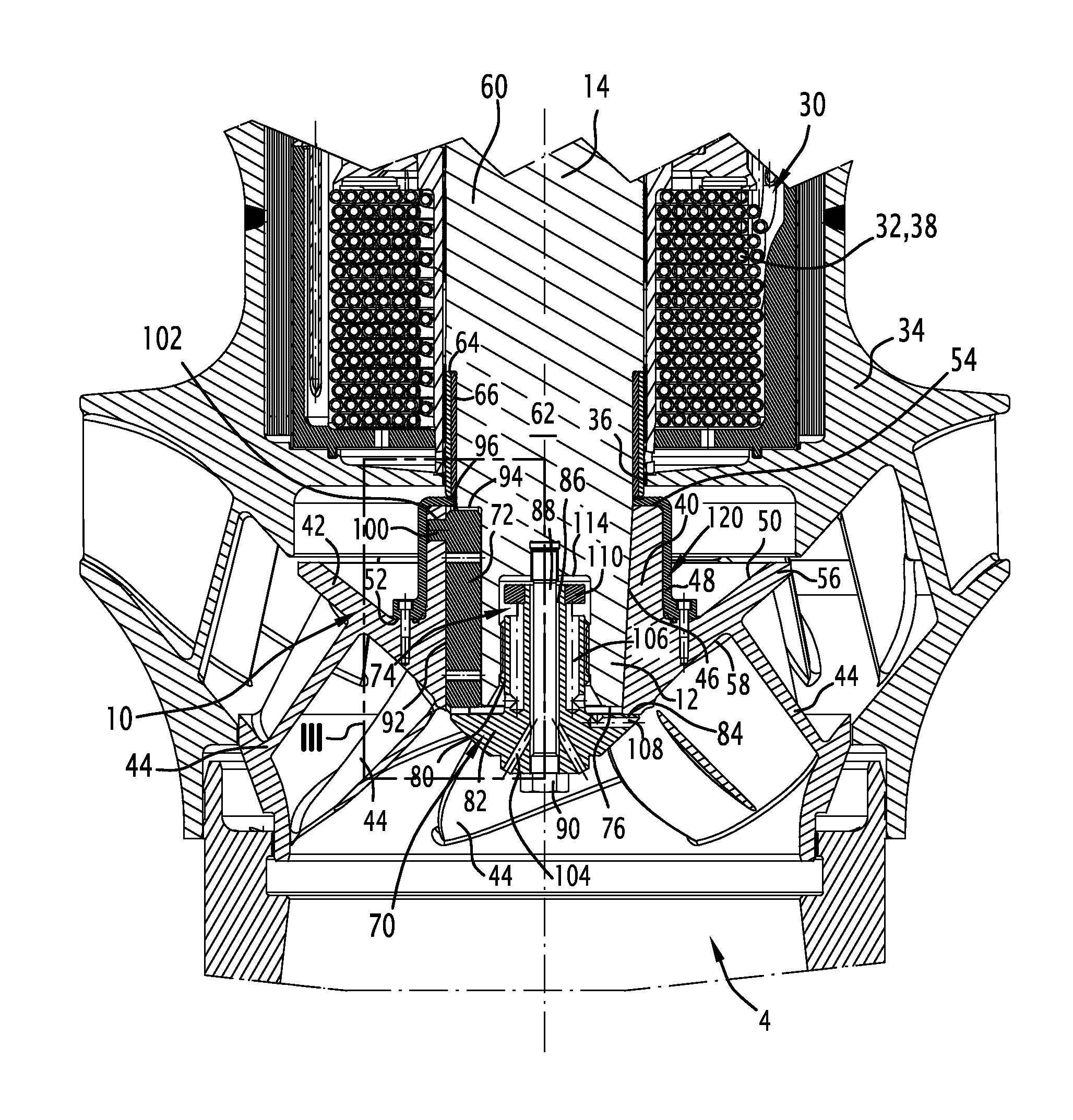

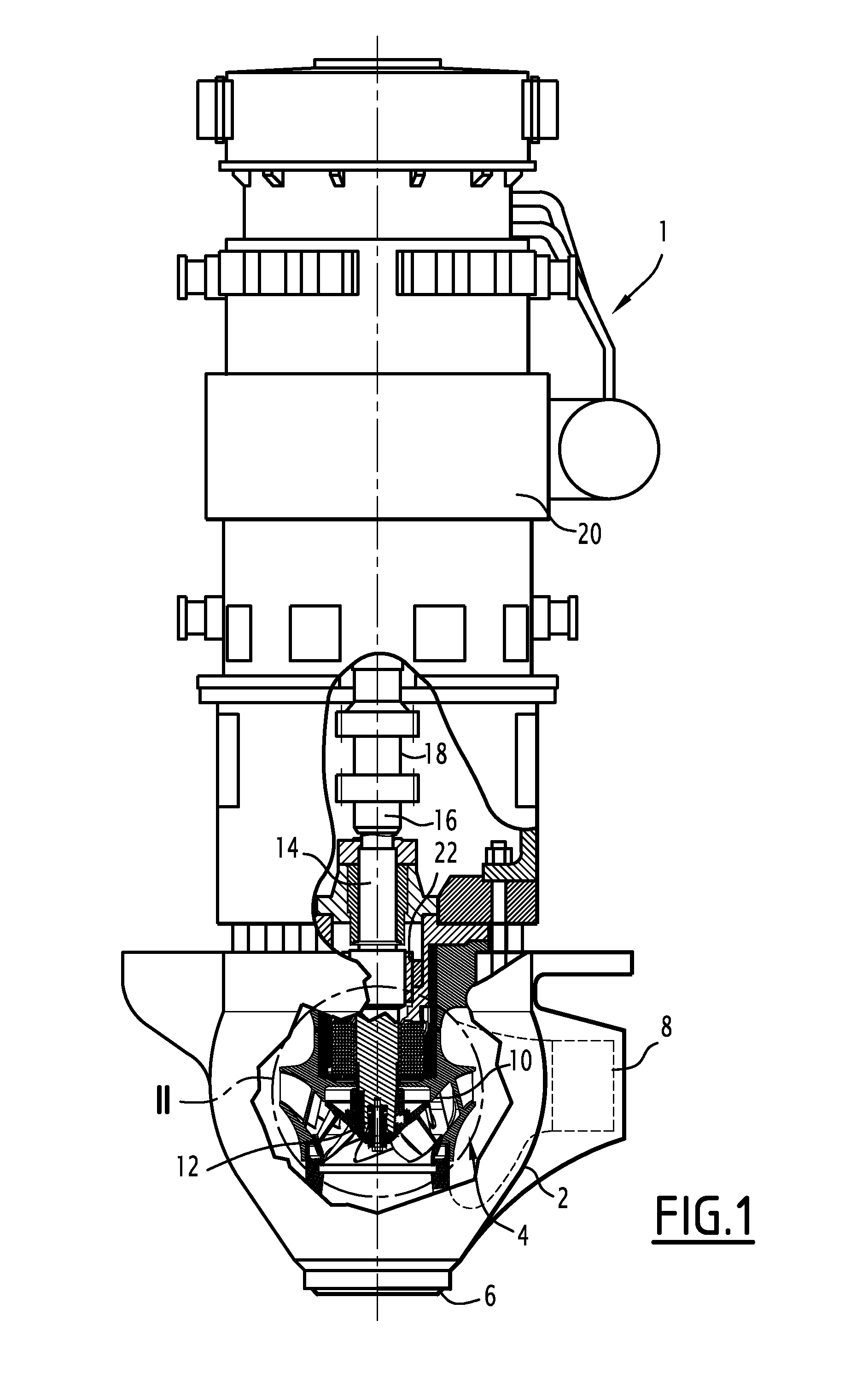

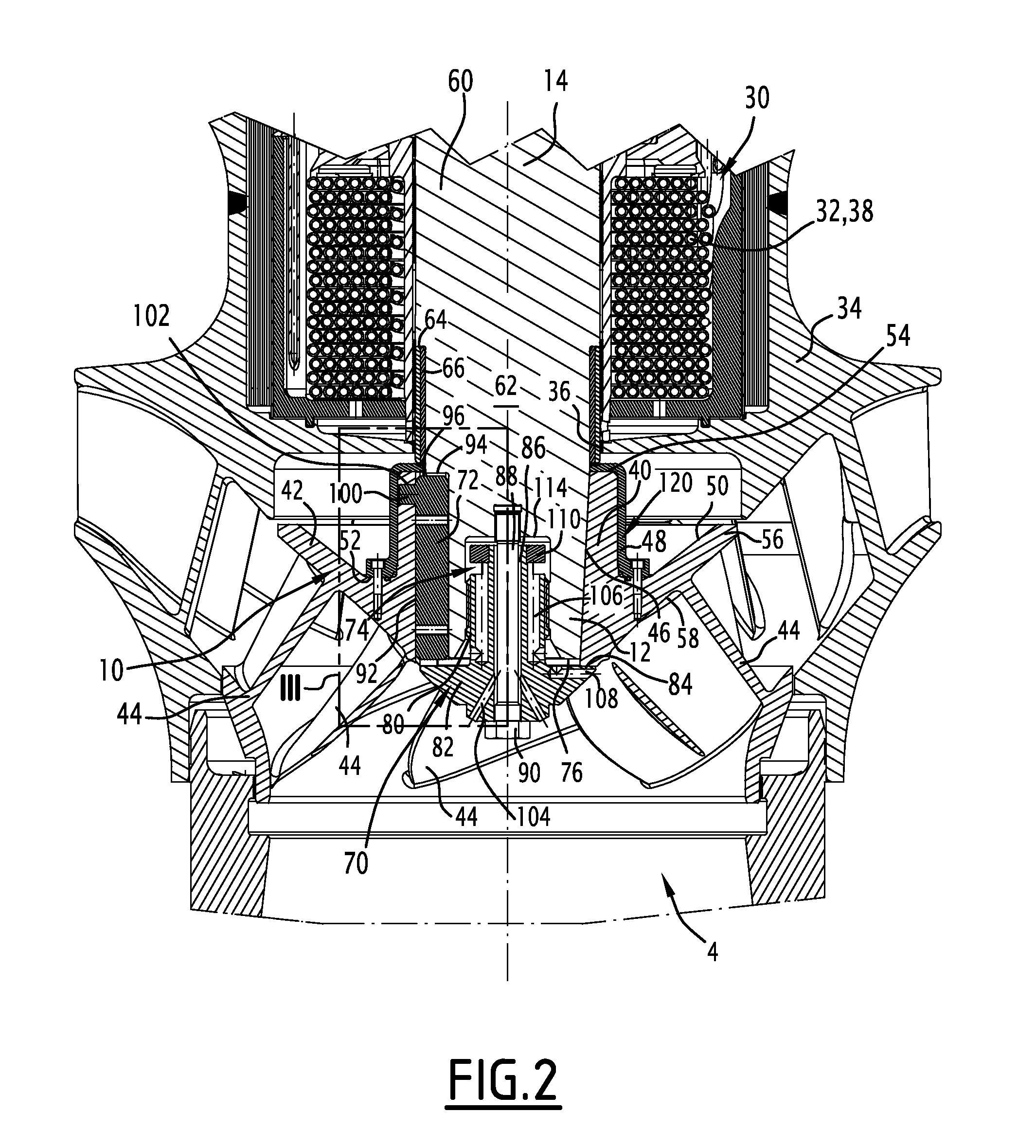

[0040]The pump 1, shown in FIG. 1, is a primary pump of a pressurized water nuclear reactor. This pump 1 is suitable for causing a heat-transport fluid to flow, in this case pressurized water at a temperature close to 300° C., in a fluid circuit, in the case at hand the primary circuit of the nuclear reactor.

[0041]To that end, the primary pump 1 includes a pump body 2 delimiting a chamber 4, or volute, for causing a heat-transport fluid to flow, fluidly connected by means of a first tubing 6 to a first line of the primary circuit and by a second tubing 8 to a second line of the primary circuit, between which the pump 1 establishes a certain pumping pressure to cause the heat-transport fluid to flow.

[0042]The pump 1 further includes a pump wheel 10 for establishing the pumping pressure between the first and second tubings 6, 8. This pump wheel 10 is bound on a lower axial end segment 12 of a driveshaft 14 oriented substantially vertically and the upper axial end segment 16 of which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com