Plunger pump power control device and control method thereof

a power control device and power control technology, applied in the direction of pump control, pump control, positive displacement liquid engine, etc., can solve the problems of high mass production cost, large manufacturing difficulty, sticking, etc., and achieve the effect of simple structure, less errors, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

A Plunger Pump Power Control Device

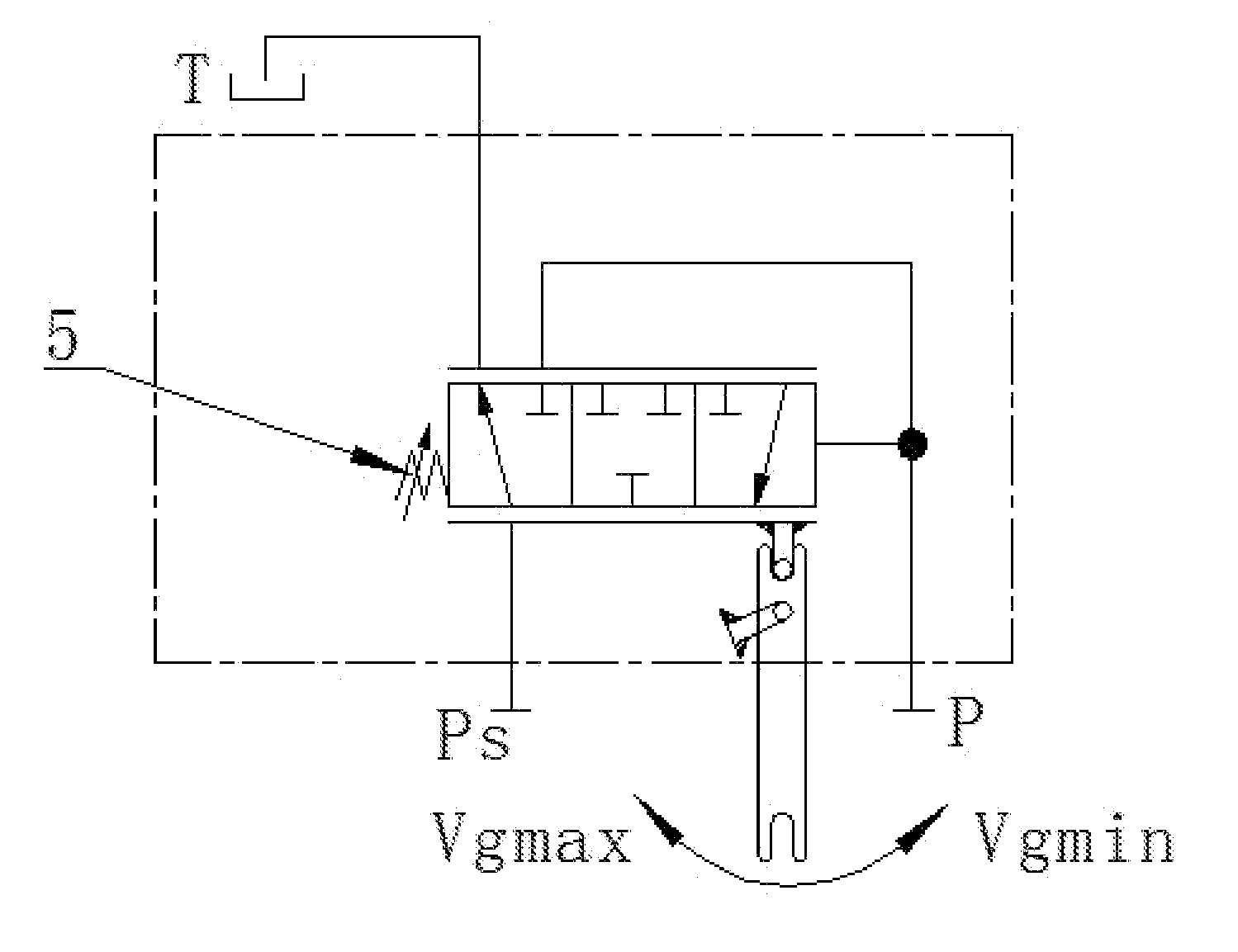

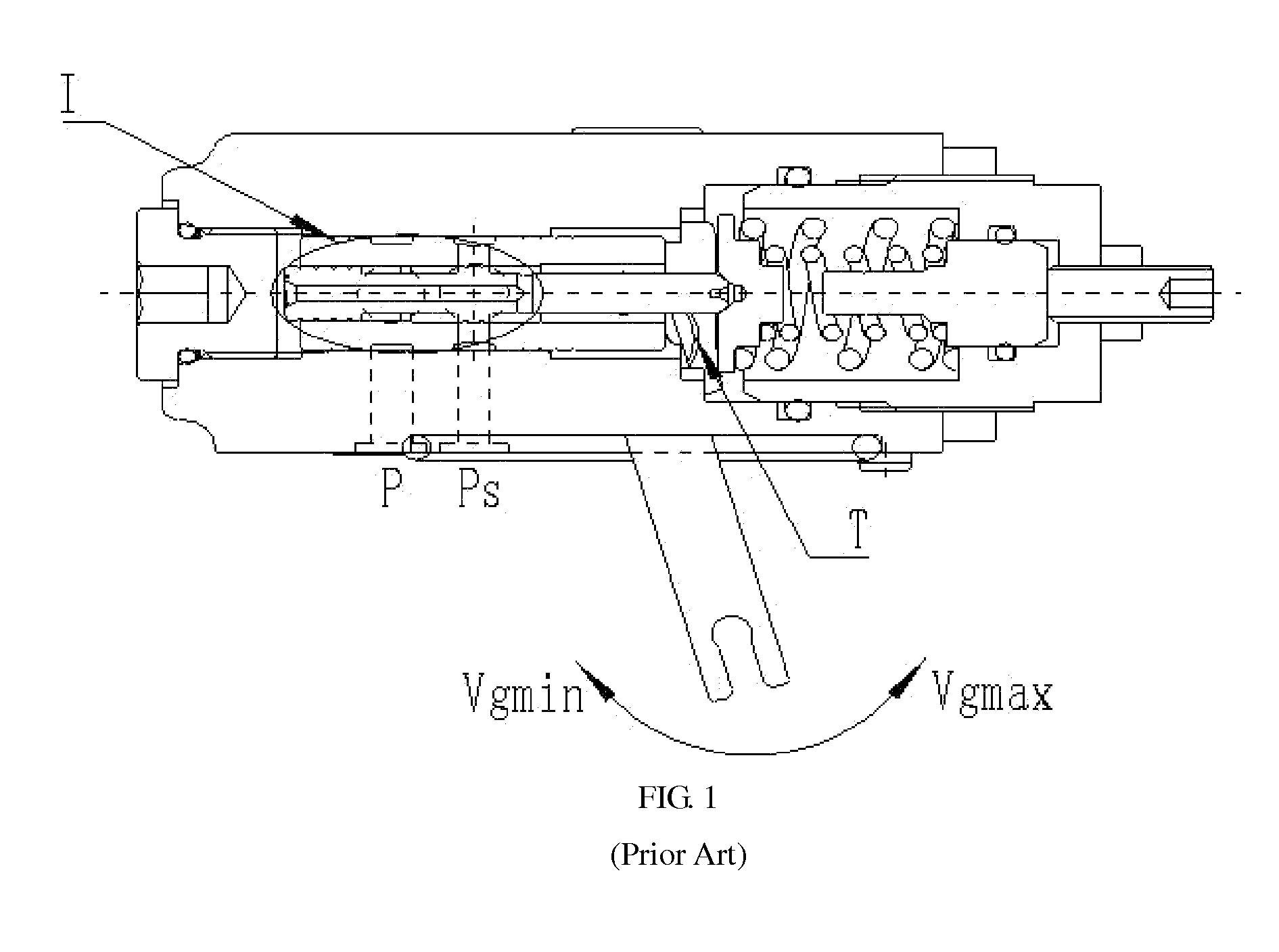

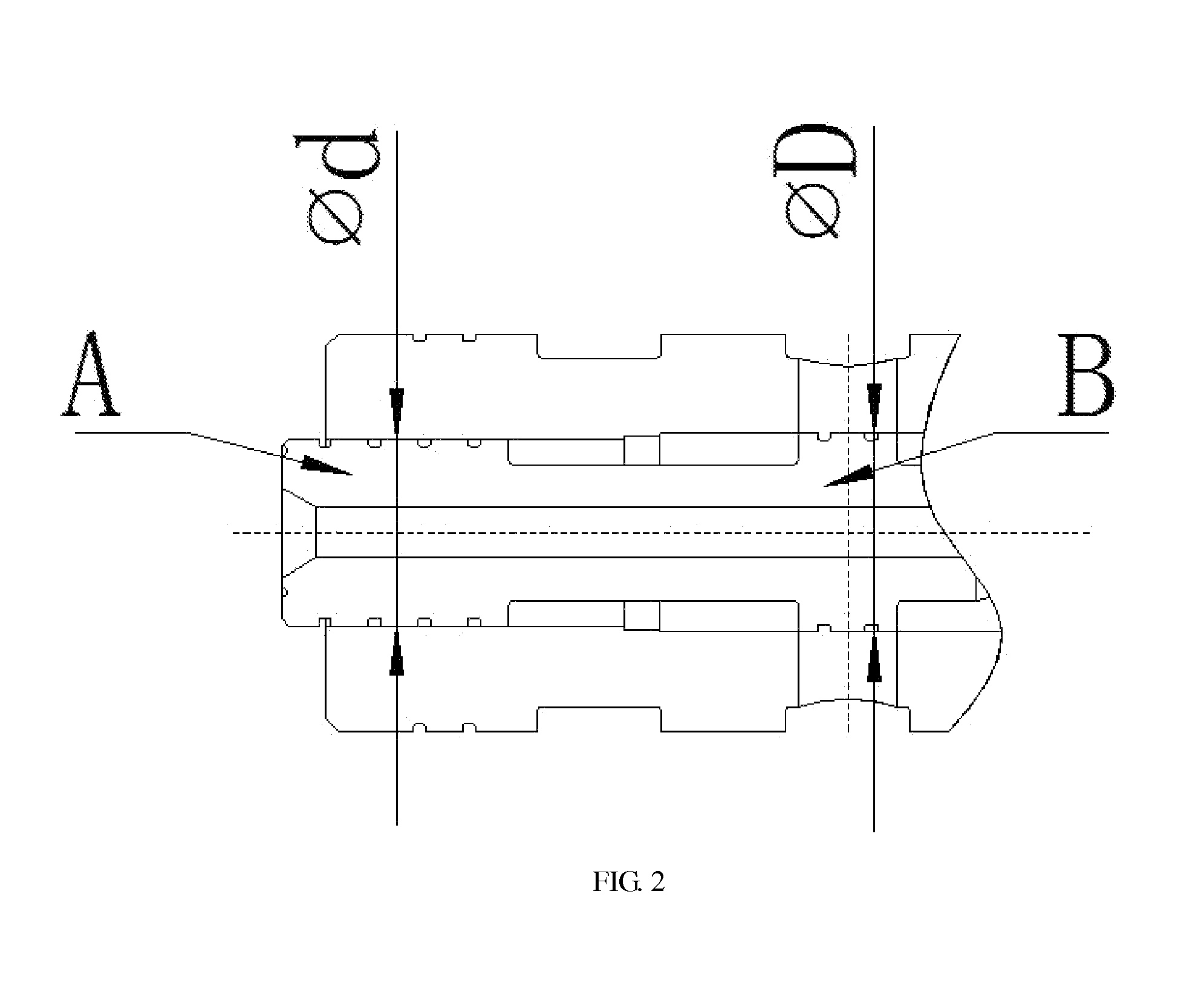

[0030]Referring to FIG. 2 to FIG. 5, a plunger pump power control device comprises a control valve body 1, a valve core 2, a valve sleeve 3, a stop screwed plug 4, a spring pre-loaded mechanism 5, a feedback mechanism 6, and a slide valve 7; an oil inlet P, an oil outlet Ps and two oil drain ports T are provided on the control valve body 1; the oil outlet Ps is externally connected to a variable piston chamber of a pump body; the valve core 2 is provided within the valve sleeve 3, the valve sleeve 3 and the valve core 2 form a 3-position two-way structure valve and an E-cavity is formed between the valve sleeve 3 and the valve core 2; the slide valve 7 is provided at the central part of one end of the valve core 2, a C-cavity is formed along a radial direction of the valve core 2 between the slide valve 7 and the valve core 2, and a ball end of the slide valve 7 contacts with the stop screwed plug 4; the stop screwed plug 4 is provided at one end o...

embodiment 2

A Control Method for a Plunger Pump Power Control Device

[0035]A control method for a plunger pump power control device specifically comprises the following steps of:

[0036](1) presetting the value of a spring pre-loaded mechanism 5;

[0037](2) introducing oil at a pump outlet pressure from an oil inlet P into a C-cavity of a valve core 2 through a valve sleeve 3, wherein the oil at the pump outlet pressure drives the slide valve 7 and the valve core 2 to move in opposite directions, the slide valve stops at a stop screwed plug, and the valve core moves towards and compresses the spring pre-loaded mechanism; or the pressure at the oil inlet P is decreased so that the spring pre-loaded mechanism drives the valve core to overcome the pressure of the C-cavity to move in a reverse direction; and

[0038](3) performing binarization processing, when the pump outlet pressure introduced into the C-cavity increases to exceed the preset value of the spring pre-loaded mechanism 5, the valve core 2 mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com