Carrier channel with element concentration gradient distribution and fabrication method thereof

a carrier channel and gradient technology, applied in the field of carrier channels, can solve the problems of only applying thermal diffusion process, increasing device thermal budget and production cost, and consuming time and energy in the diffusion process, so as to reduce thermal budget and production cost, and accelerate the melting growth process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

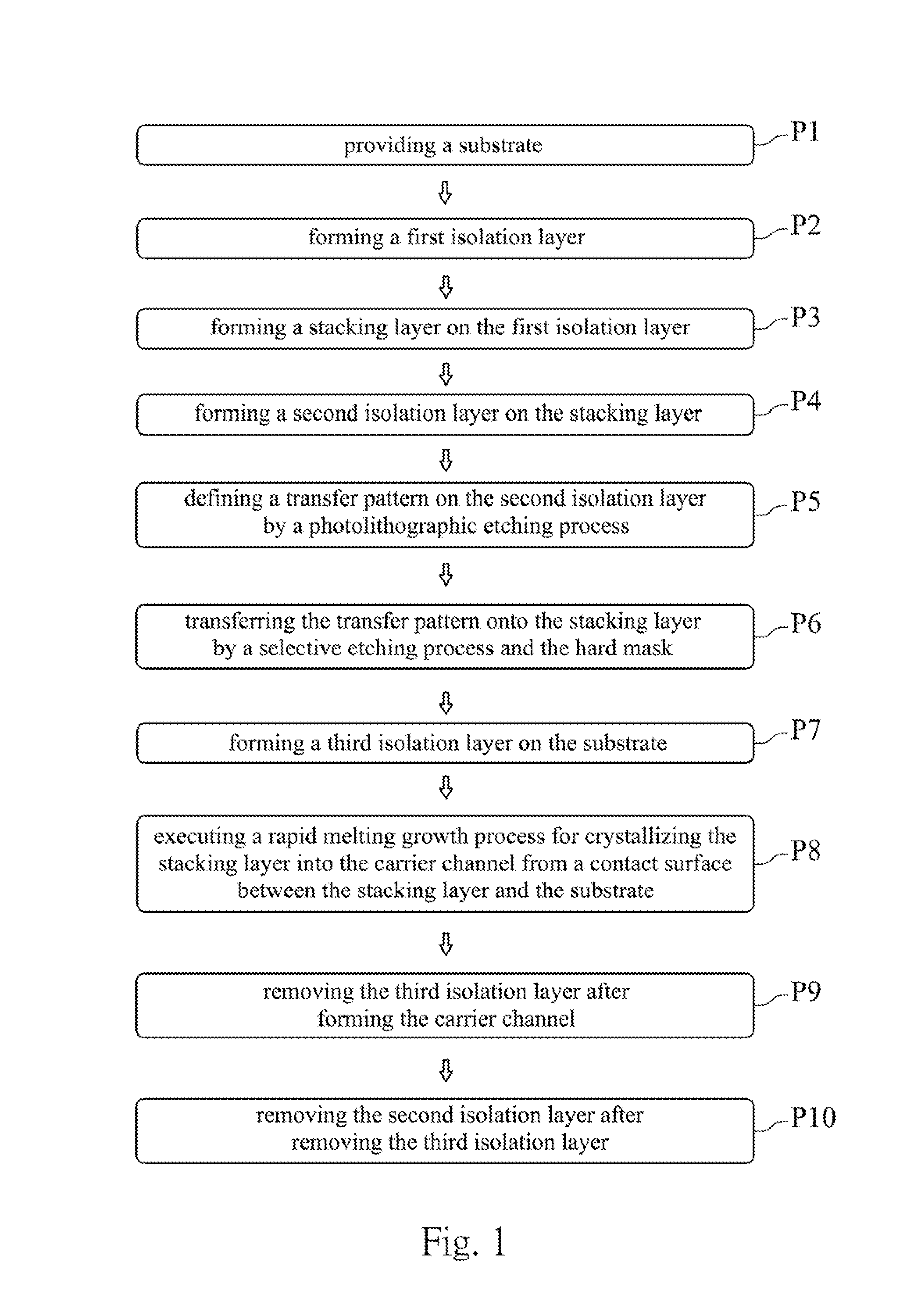

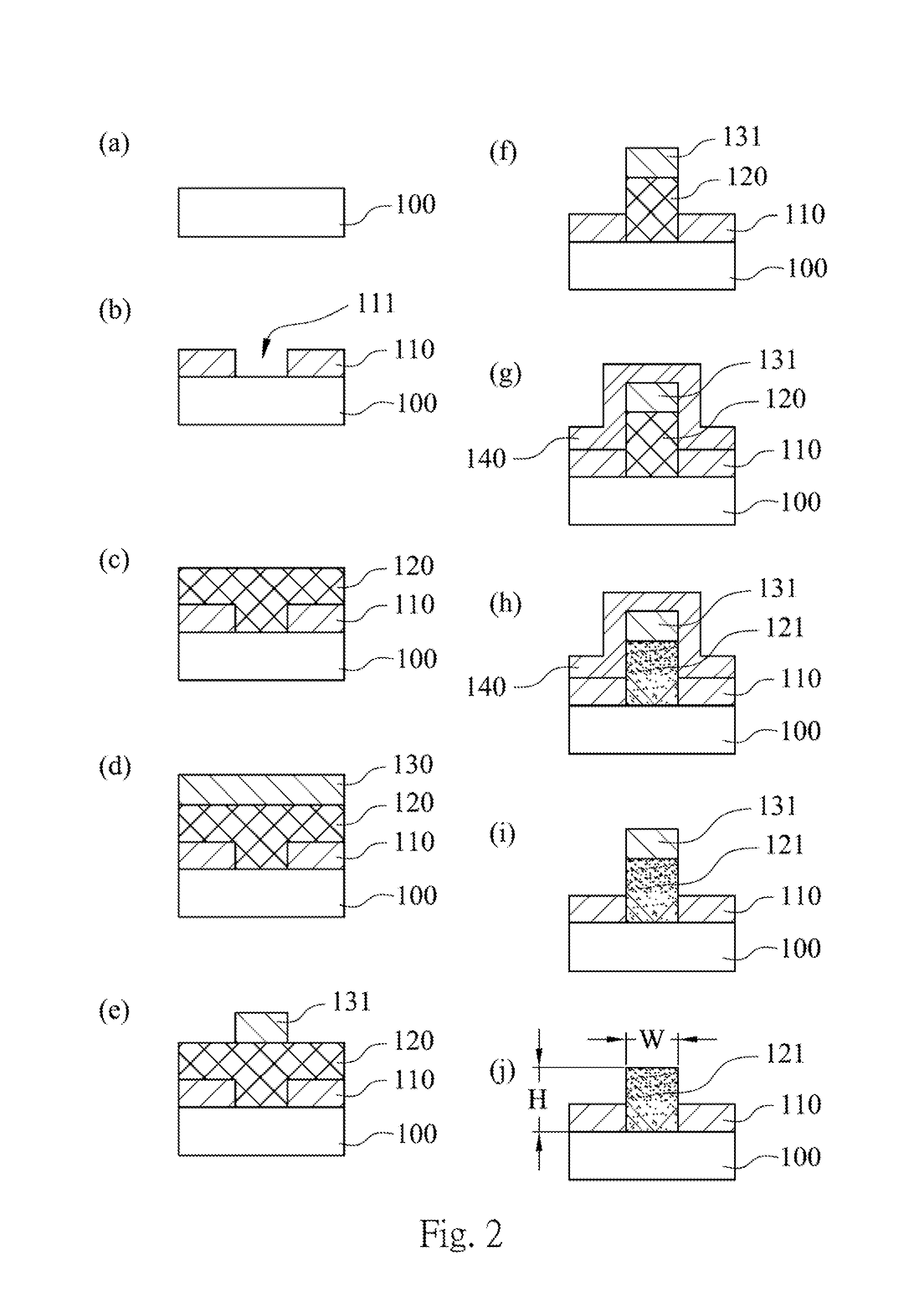

[0016]FIG. 1 is a flowchart of a fabricating method of a carrier channel with an element concentration gradient distribution according to one embodiment of the present disclosure and the fabricating method includes the following steps.

[0017]Step P1, a substrate is provided and the substrate can be made of a single-layer material or a multilayer material which are compatible with a semiconductor process. Therefore, the carrier channel fabricated by the fabricating method can be integrated with the other semiconductor element on a chip. The substrate can be a monocrystalline silicon substrate, a polycrystalline silicon substrate or an amorphous silicon substrate.

[0018]Step P2, a first isolation layer is formed on the substrate and the first isolation layer has a first through hole. The first through hole is formed through the first isolation layer. The shape of the first through hole can be varied on demand. Furthermore, the first isolation layer can be an oxide layer or a nitride lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com