Press machine and pressing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

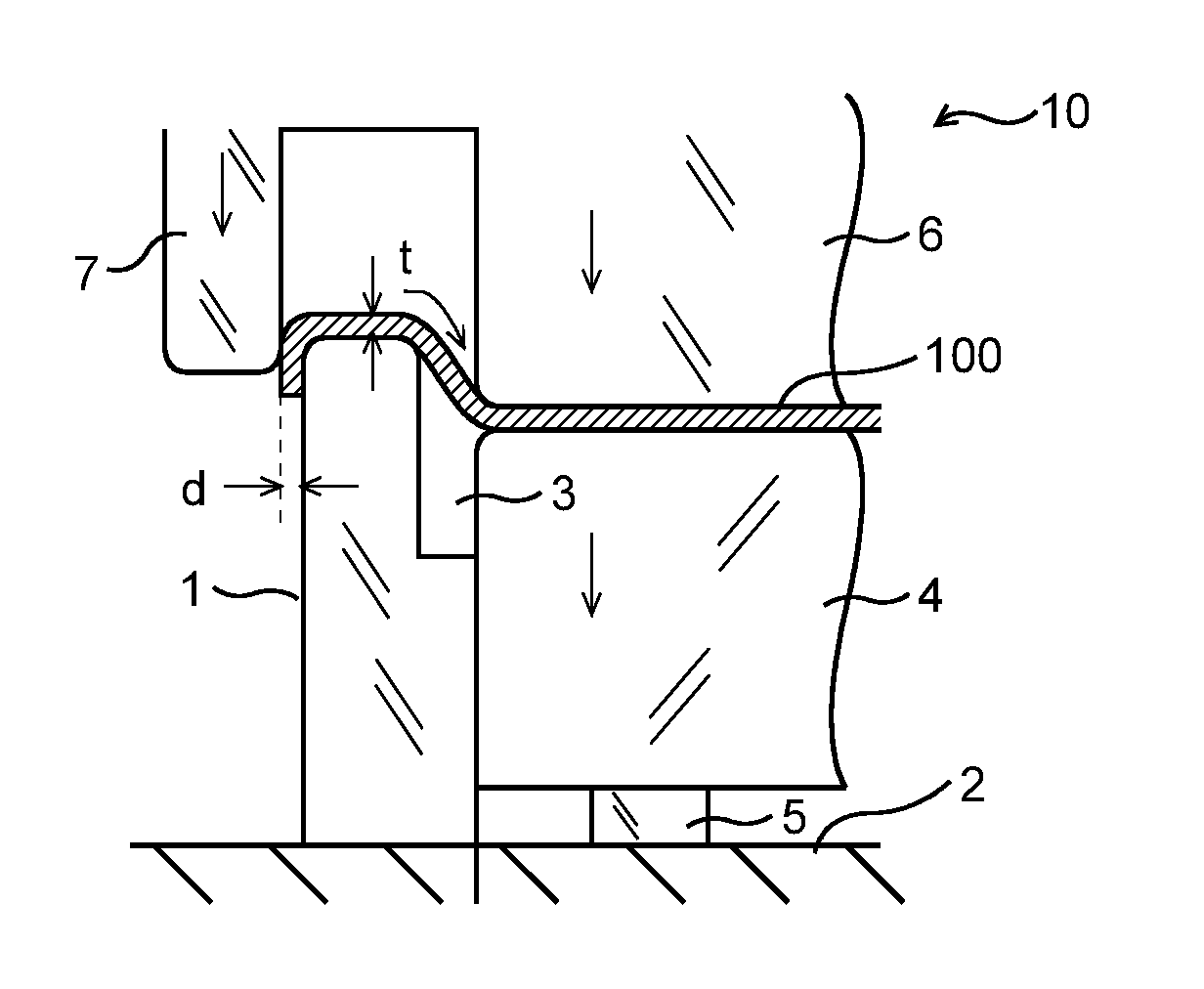

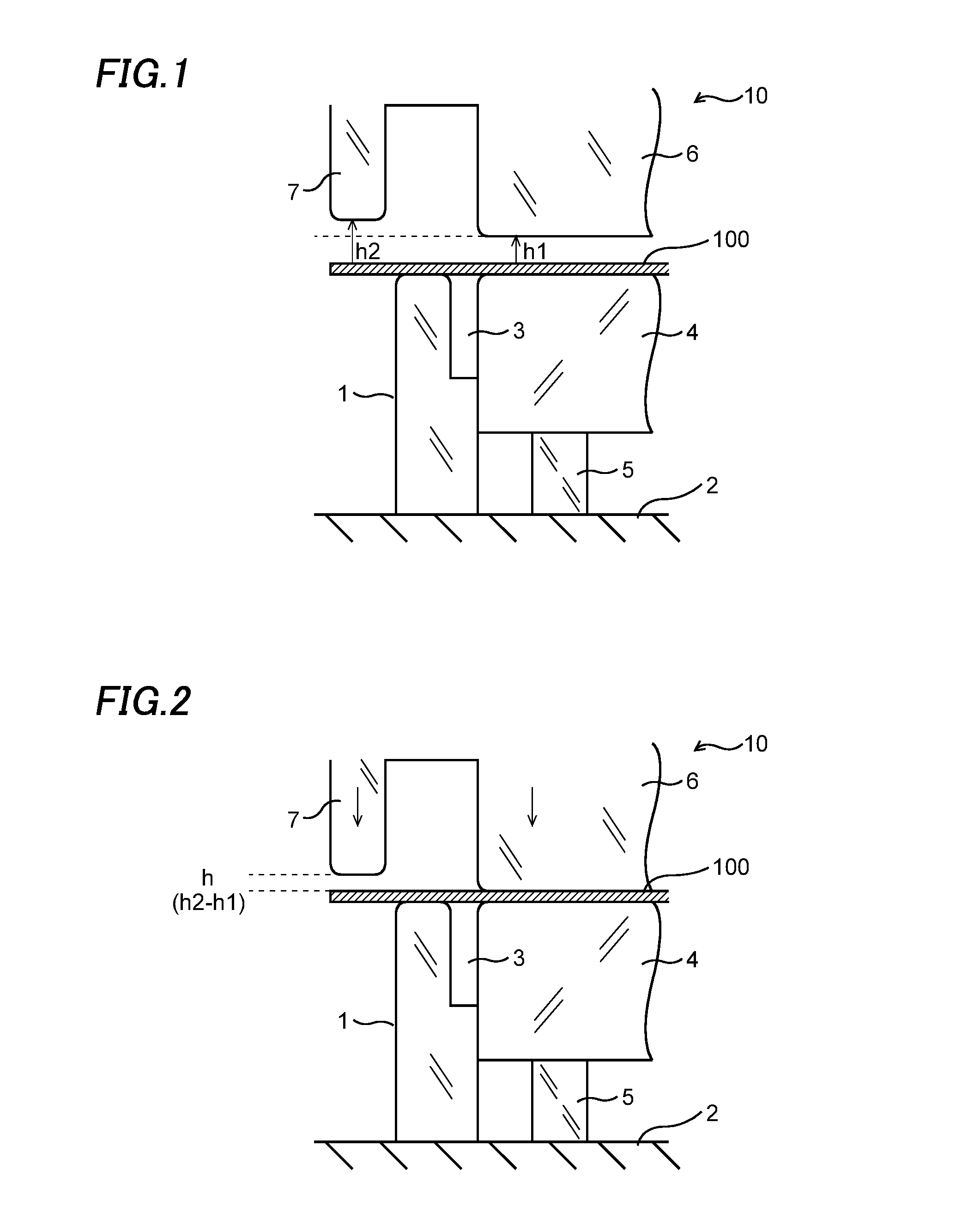

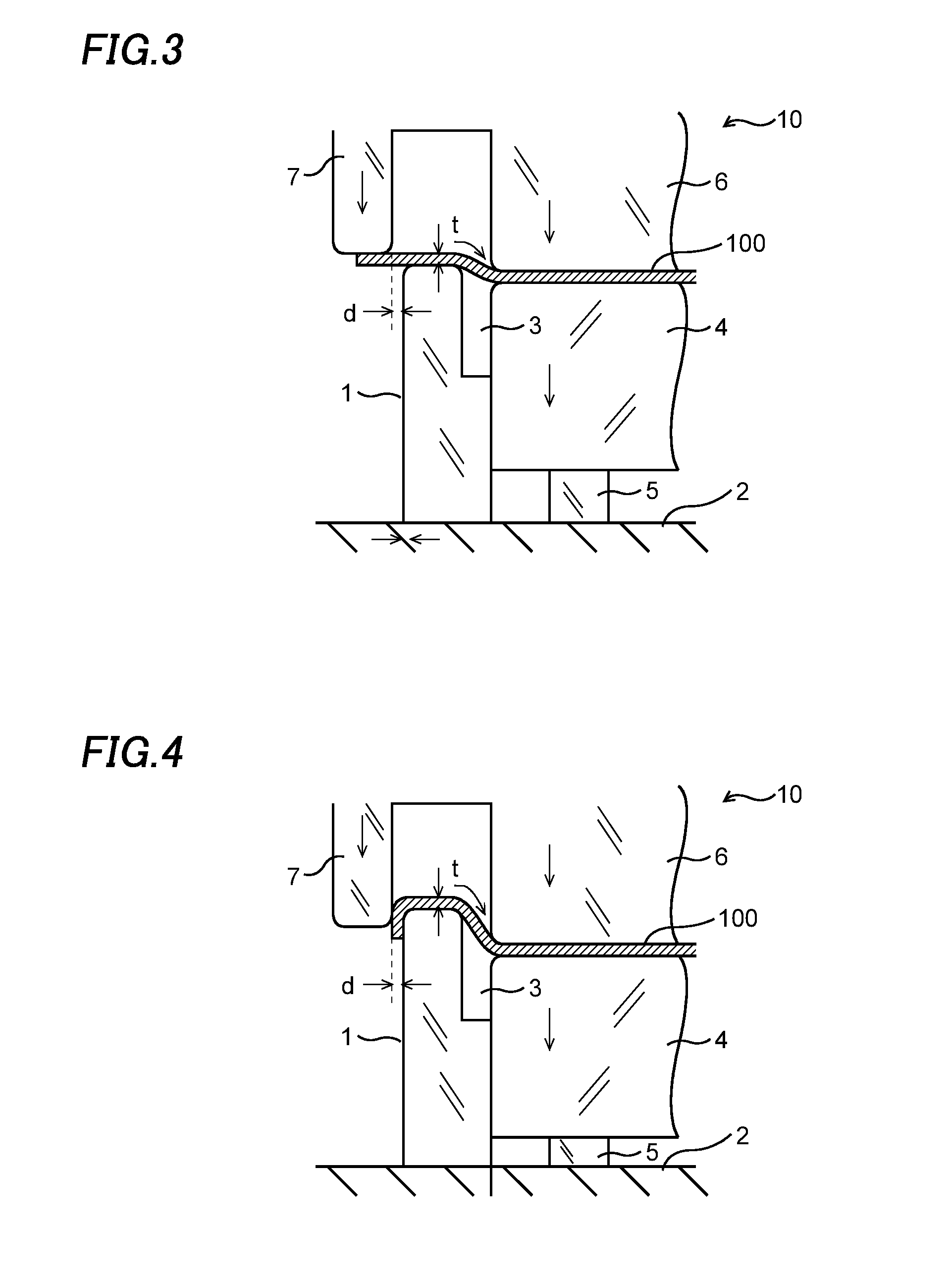

[0018]An embodiment of the invention will be described referring to the figures. FIG. 5 is a partial plan view of a press machine 10, and FIGS. 1 to 4 are cross-sectional views of FIG. 5 along line X-X.

[0019]As shown in the figures, a lower die 1 is fixed on a base 2 and has a step portion 3 for forming a bent portion on a side surface. A pad portion 4 is disposed adjacent to the lower die 1 on the step portion 3 side in the horizontal direction. A portion of one side surface of the pad portion 4 is in contact with the lower side surface of the lower die 1 below the step portion 3.

[0020]The pad portion 4 is supported by a spring 5 (e.g. a gas spring) disposed on the base 2, being movable upward and downward.

[0021]An upper die 6 is disposed opposing the pad portion 4 in the vertical direction. A regulation portion 7 is disposed adjacent to the upper die 6 in the horizontal direction on the outside of the end of the lower die 1 in the horizontal direction. As shown in the cross-sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com