Component reachable expandable heat plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

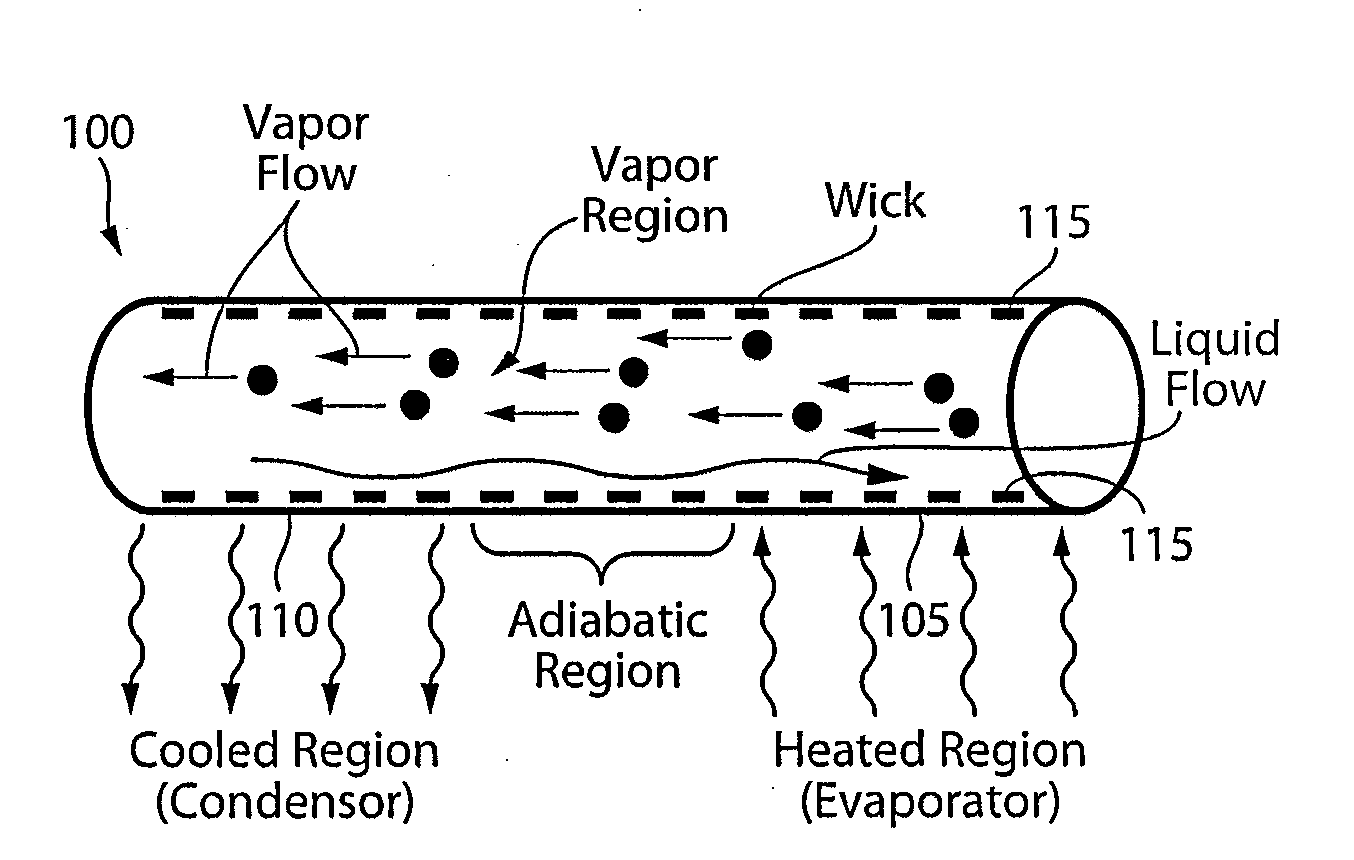

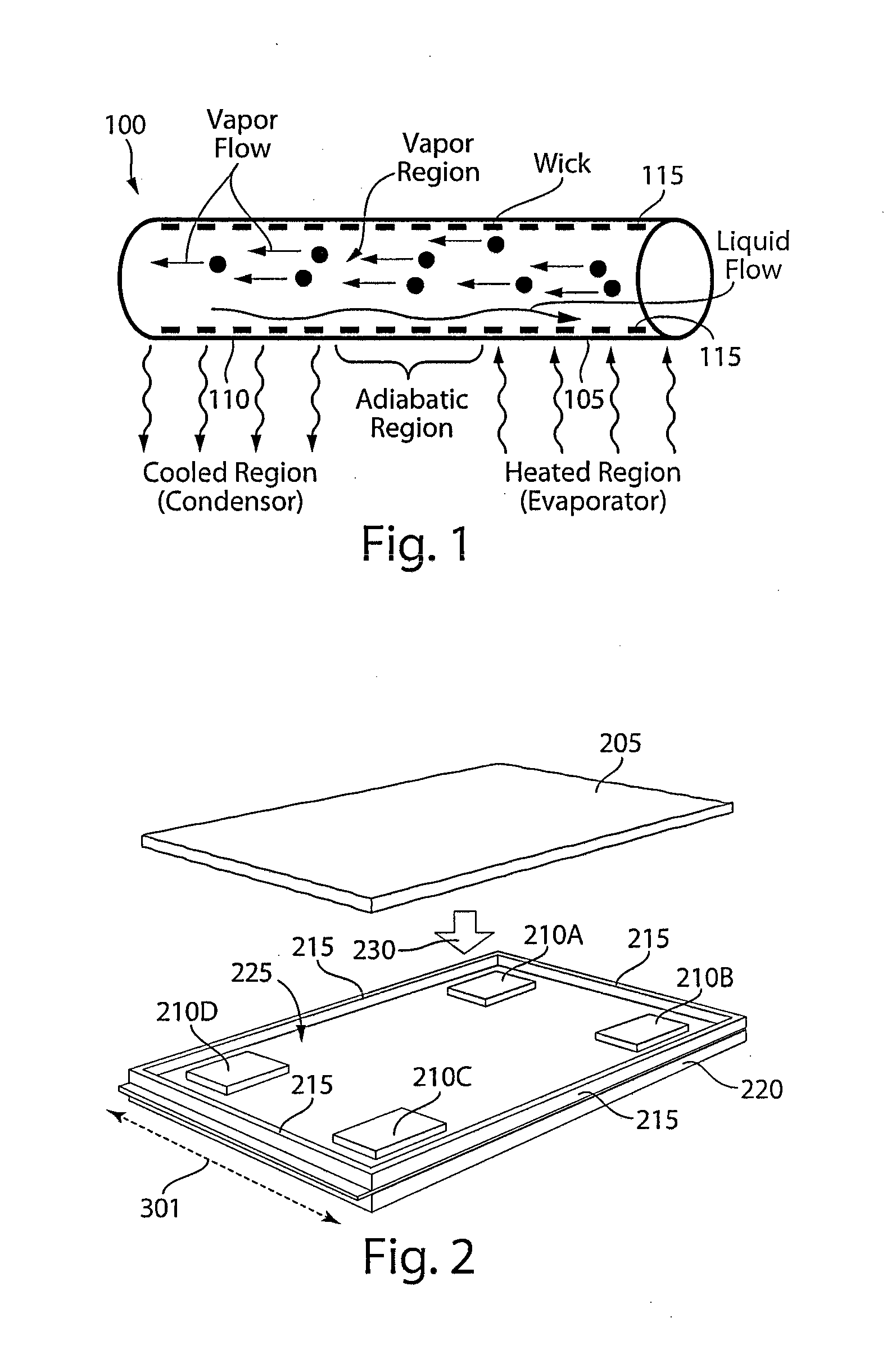

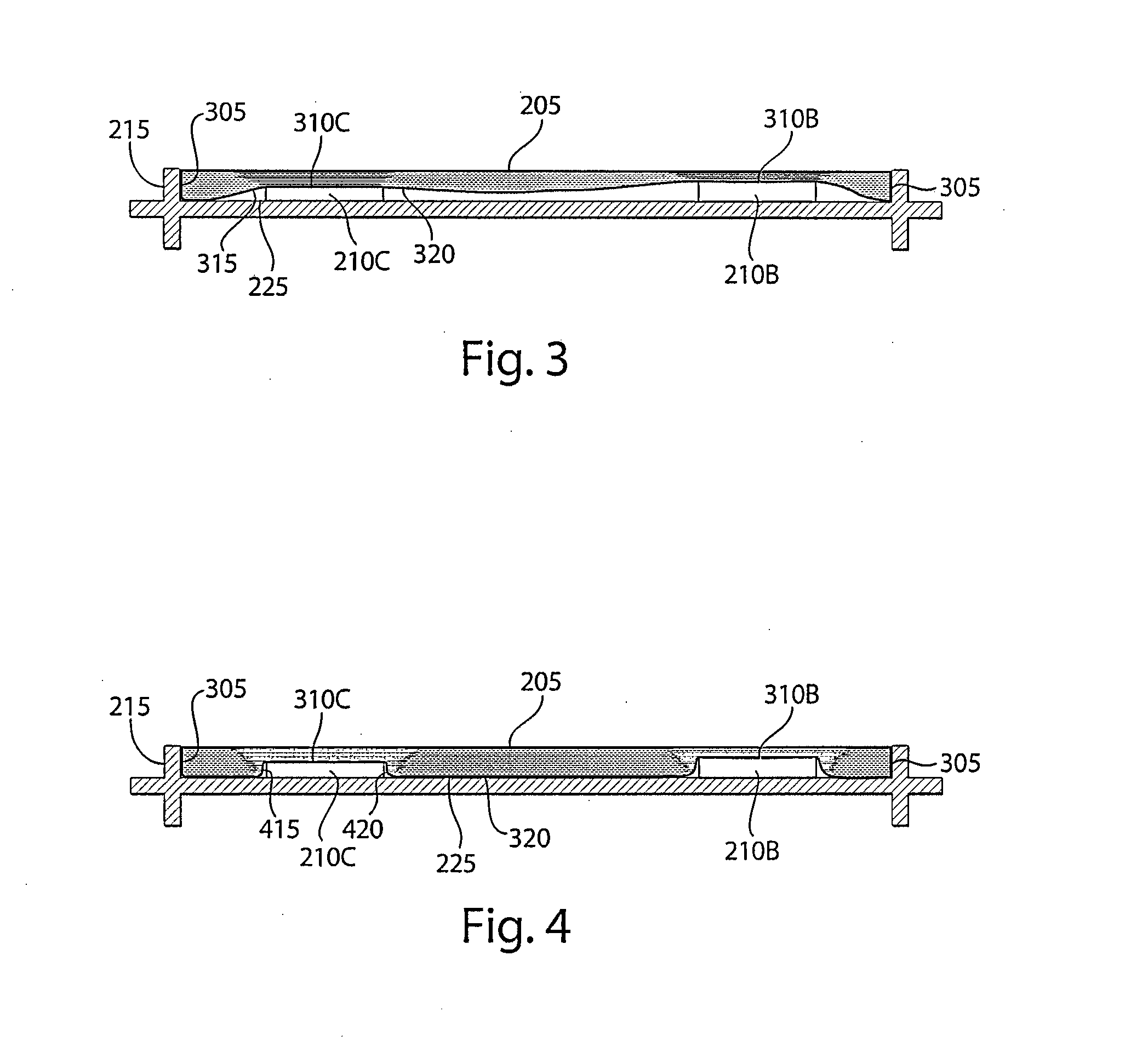

[0017]Some embodiments of the invention provide a heat plate system which includes a closed vessel having at least one surface that is pliable and / or flexible, allowing the vessel to come into close contact with contoured surfaces of heat-generating components of varying heights, and enabling effective heat transfer away from those components. In some embodiments of the invention, a heat plate may be expandable, such as upon the absorption of heat, so as to increase the component surface area with which the heat plate system comes into contact, and thereby improving thermal conductivity. In addition, some embodiments of the invention may provide a heat plate system for use with heat-generating components residing in a module housing which is designed to conduct heat to the housing's peripheral walls and / or a cooling mechanism, rather than to the housing's cover, to provide greater control and effectiveness with respect to heat transfer than conventional systems provide.

[0018]FIG. 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com