Buoyant target with laser reflectivity

a laser reflectivity and inflatable target technology, applied in the direction of reflecting targets, weapons, sport apparatus, etc., can solve the problems of not properly simulating the movement of a true battle target, unable to empty many conventional drogue chutes, and inability to provide a large number of “hard targets”

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

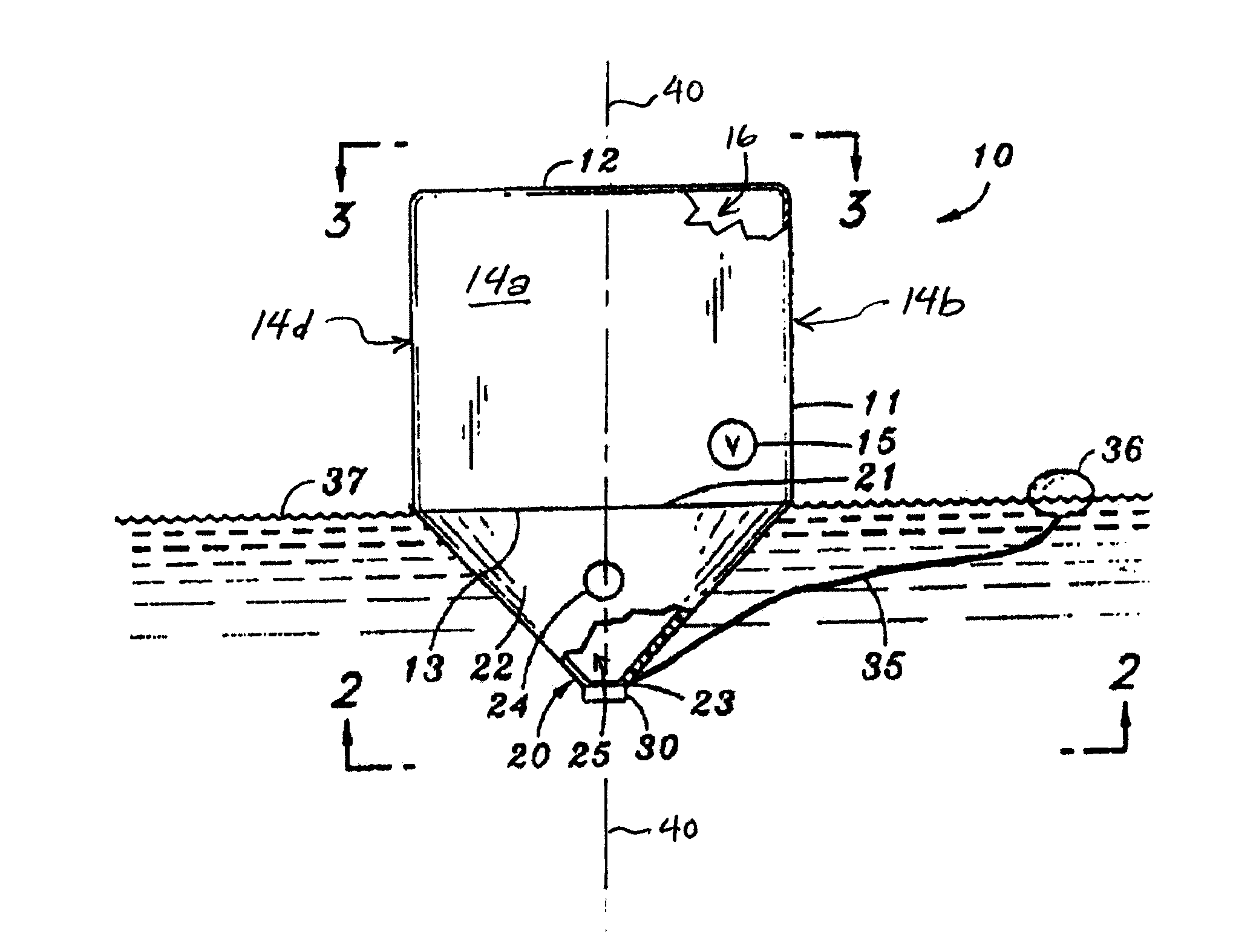

[0029]Referring now in more detail to the exemplary drawings for purposes of illustrating embodiments of the invention, wherein like reference numerals designate corresponding or like elements among the several views, there is shown in FIGS. 1-4 a buoyant target 10 made of a flexible membrane material so it can be collapsed and folded to a small bulk. Part of the buoyant target 10 can be inflated for deployment on water. The membrane material is impermeable to the inflating gas. Suitable materials include without limitation polyvinyl chloride and polyethylene sheeting, which are preferable because structural seams can be heat sealed, solvent sealed, or cemented as desired.

[0030]The buoyant target 10 has an inflatable structure 11 that comprises a top panel 12, a bottom panel 13 and a sidewall 14 which enclose an air-filled chamber 16 upon deployment. The inflatable structure is substantially airtight. The sidewall 14 is rectangular and has a front panel 14a, a right panel 14b, a rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com