Oil pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]In the following, embodiments of the present invention will be described with reference to the attached drawings.

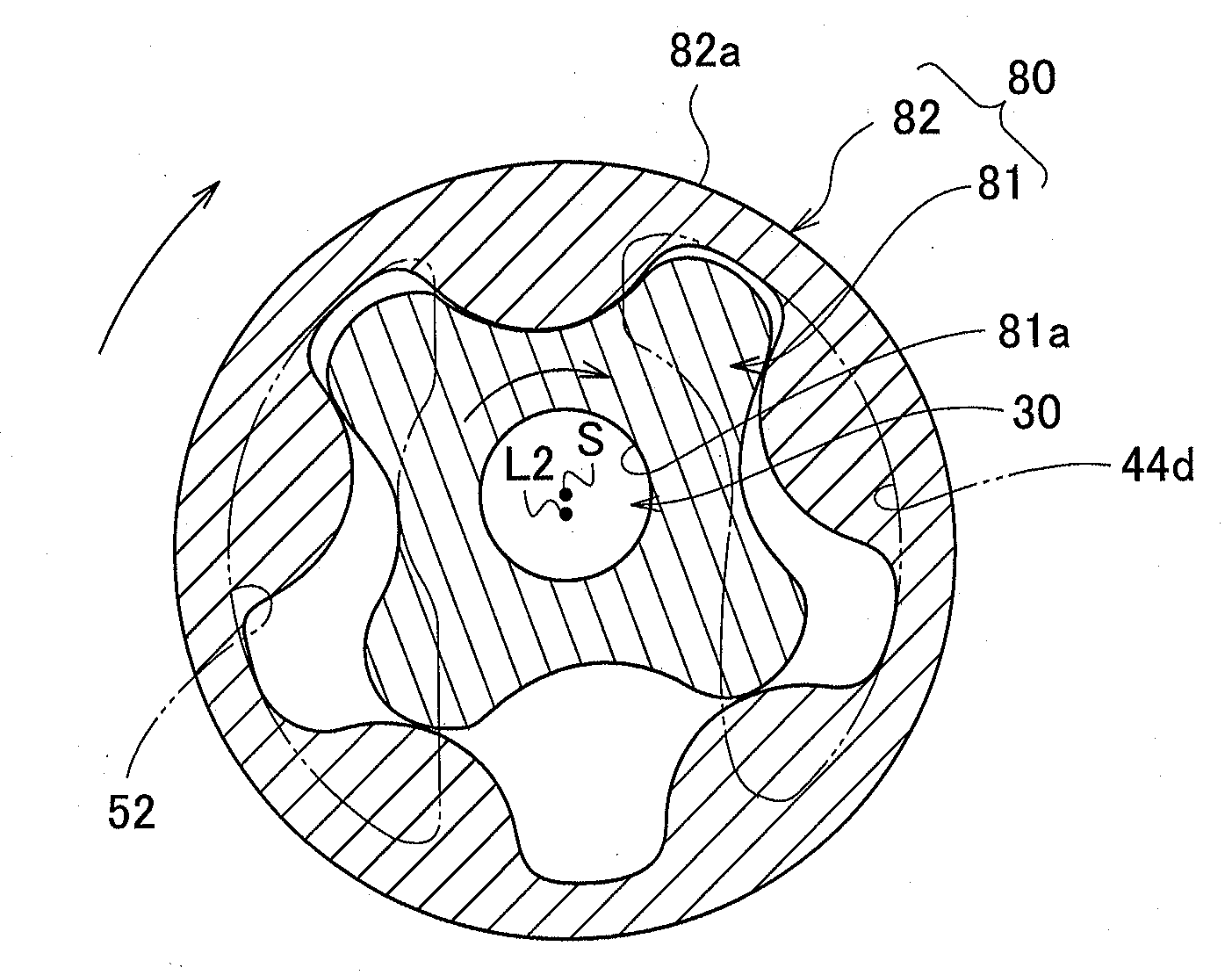

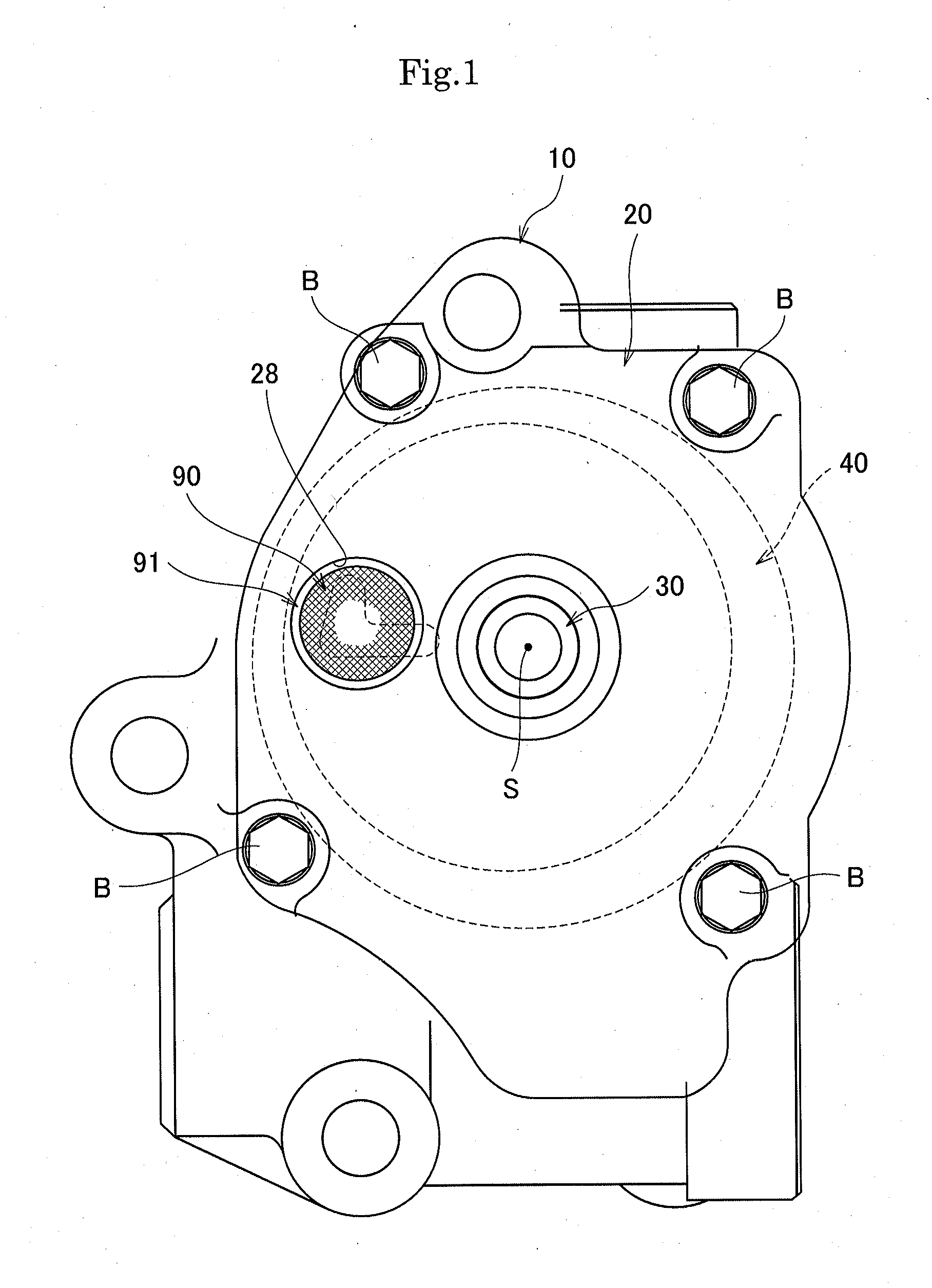

[0041]As illustrated in FIGS. 1 and 2, an oil pump according to an embodiment includes a housing body 10 and a housing cover 20 which constitute a housing, a rotary shaft 30 which is supported by the housing as being rotatable about an axis line S, a rotor case 40 which is assembled in the housing, a side plate 50 which is in contact with an end face of the rotor case 40, an O-ring 60 as an urging member which urges the side plate 50 toward the rotor case 40 in the direction of the axis line S, an upstream rotor 70, including a first inner rotor 71 and a first outer rotor 72, which is contained in the rotor case 40, a downstream rotor 80, including a second inner rotor 81 and a second outer rotor 82, which is contained in the rotor case 40 as being adjacent to the upstream rotor 70 in the direction of the axis line S, a filter member 90 which is attached to the hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com