Airlift pump with helical flow pattern

a flow pattern and airlift pump technology, applied in the direction of machines/engines, machine/engines, and removal of fluids, can solve the problems that airlift pumps by nature cannot achieve the efficiency or the lifting height of motorized mechanical pumps, and achieve the effect of enhancing the entrainment of more fluid through the device, reducing pressure, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

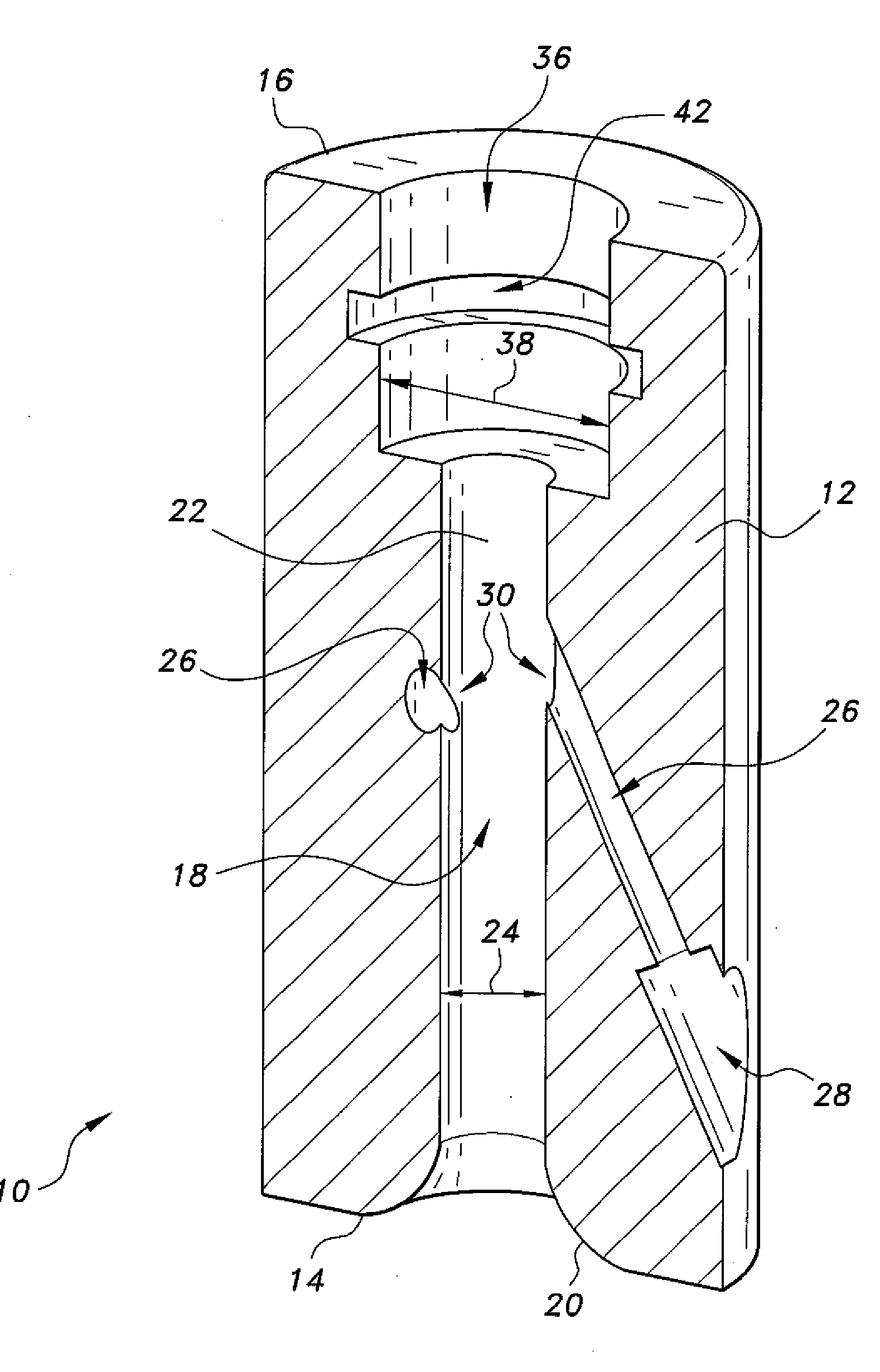

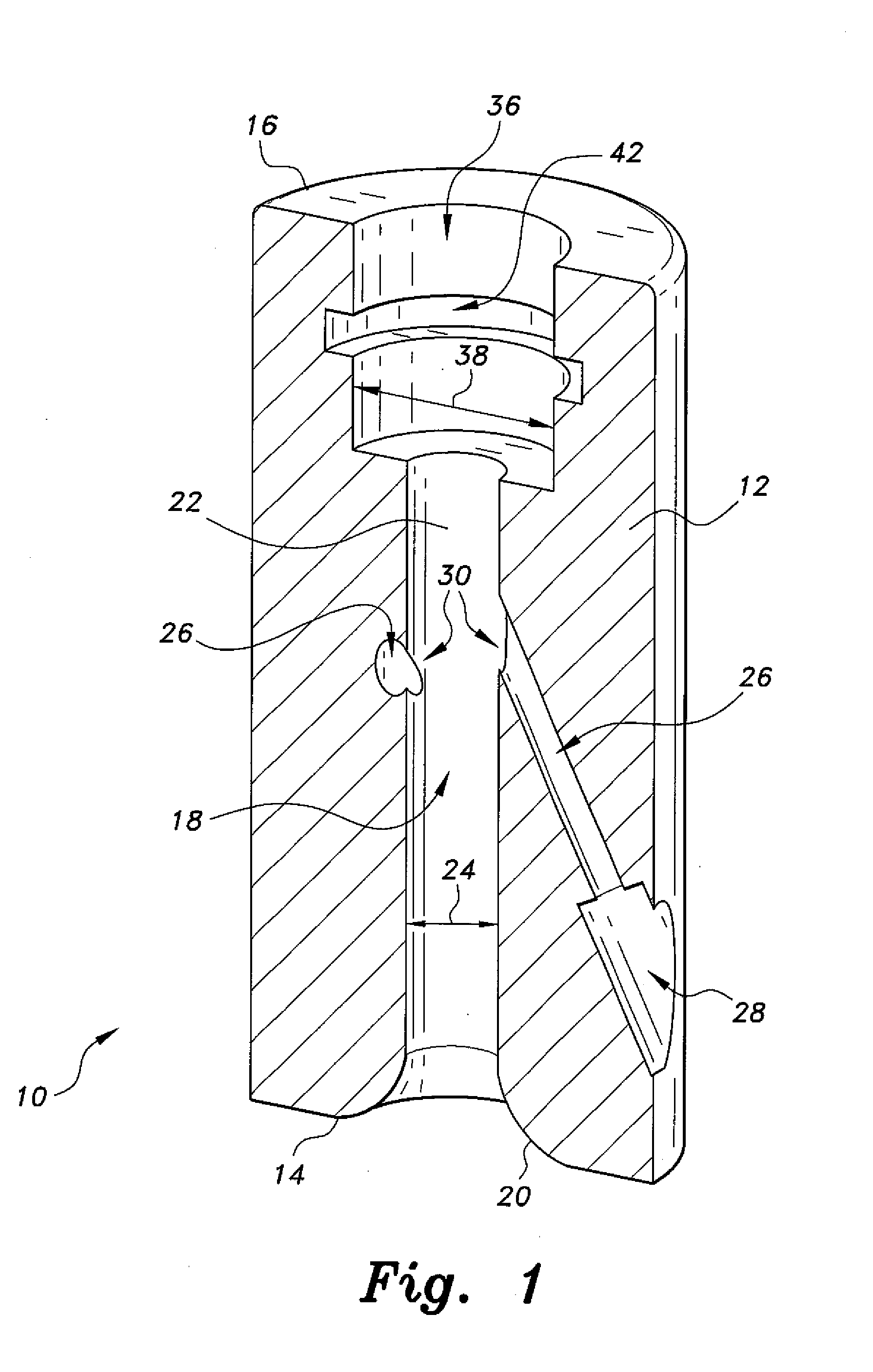

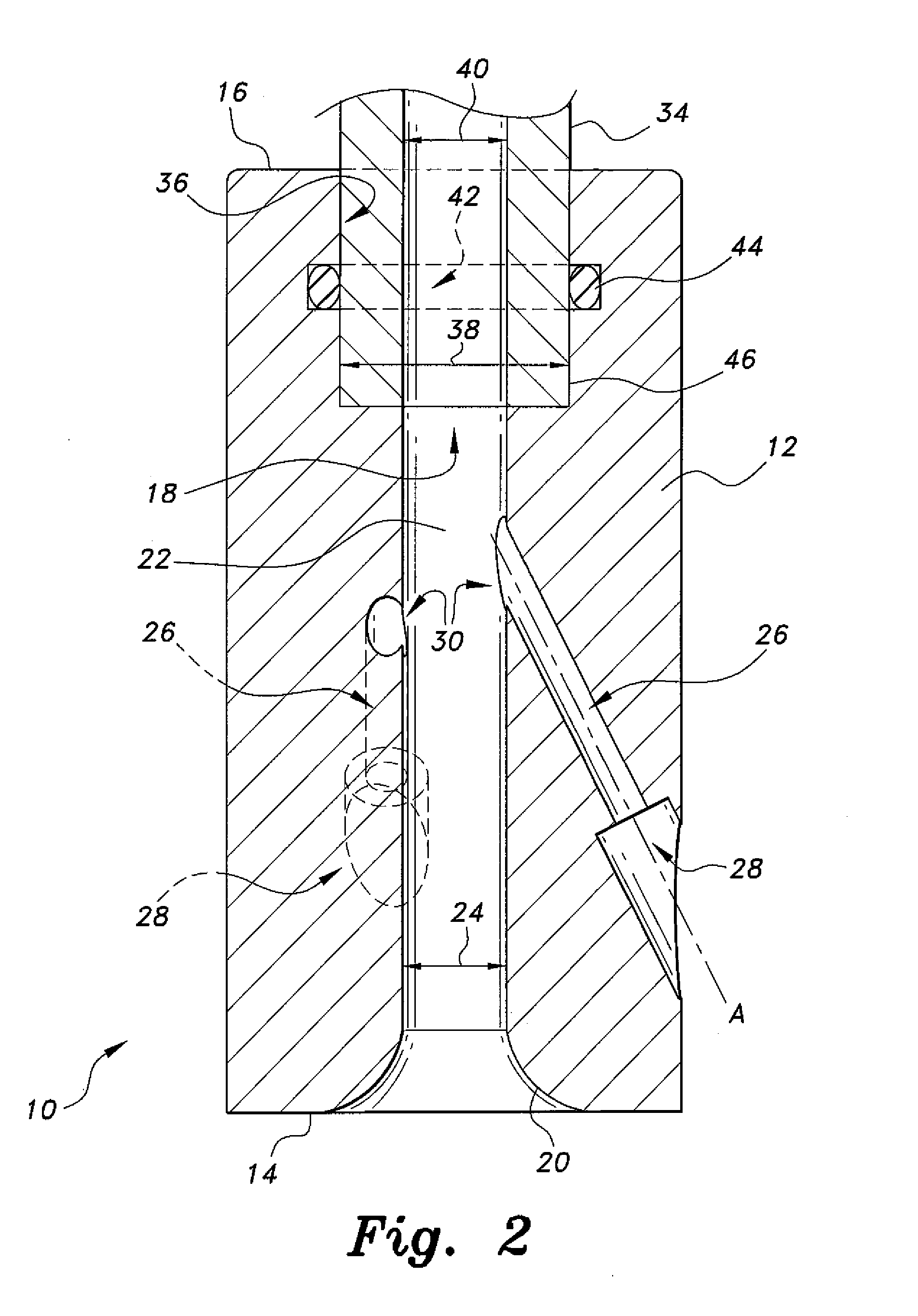

[0016]The airlift pump having a helical flow pattern includes a plurality of air or gas injection nozzles disposed tangentially to the wall of the central passage and inclined toward the upper or outlet end of the passage to impart a helical flow to liquid entrained in the device. This helical flow pattern imparts additional energy to the liquid flow through the device in comparison to conventional flow patterns, thereby increasing the lift height of the liquid pumped through the device.

[0017]FIG. 1 of the drawings provides a perspective view in section of the airlift pump with helical flow pattern, designated generally as 10 in the drawings. FIG. 2 provides an additional elevation view in section of the airlift pump 10 that also shows the attachment of a riser pipe to the upper end of the device. The airlift pump 10 comprises a nozzle body 12 having a lower inlet end 14 and an opposite upper outlet end 16. A fluid flow passage 18 is disposed concentrically within the nozzle body 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com