Firearm Suppressor Mounting Device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

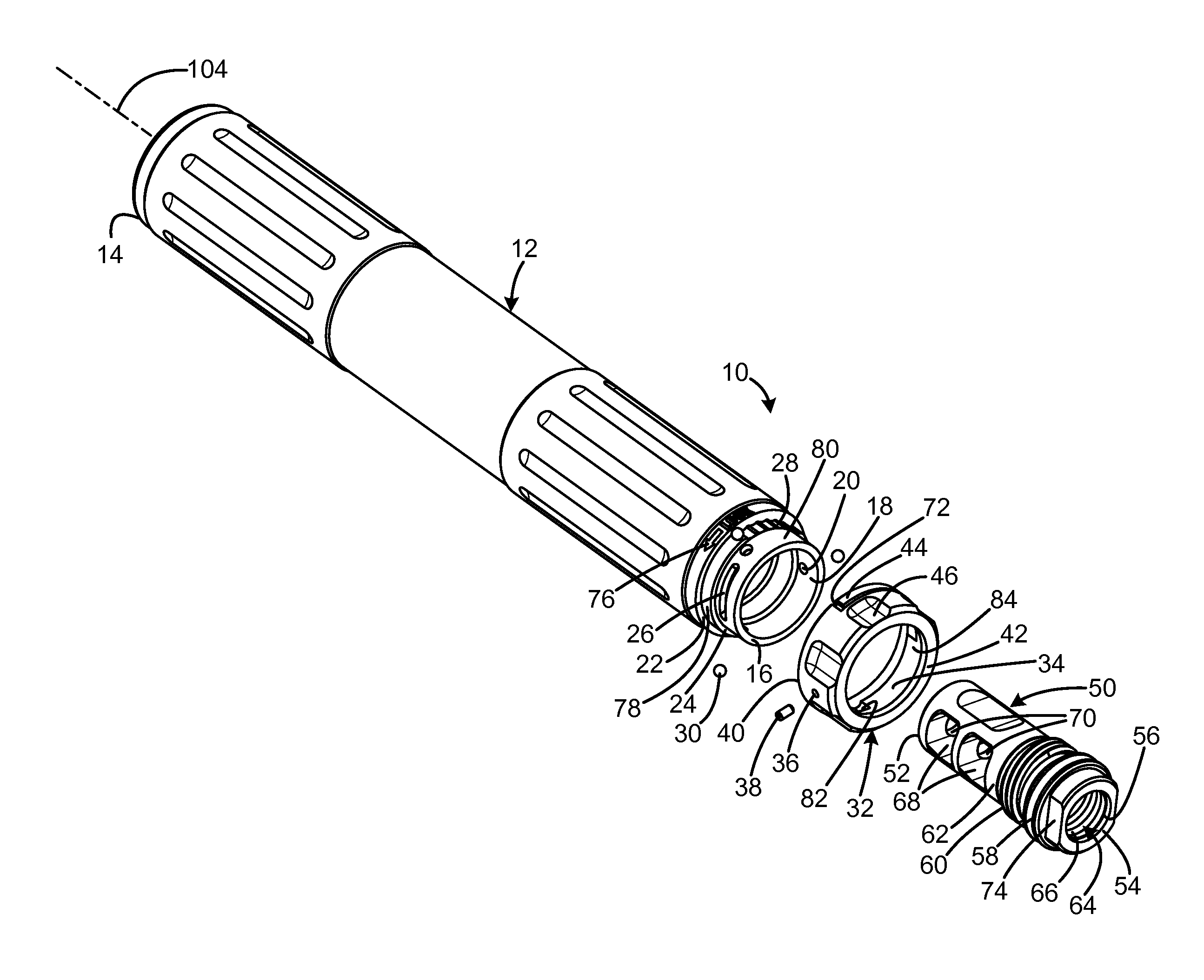

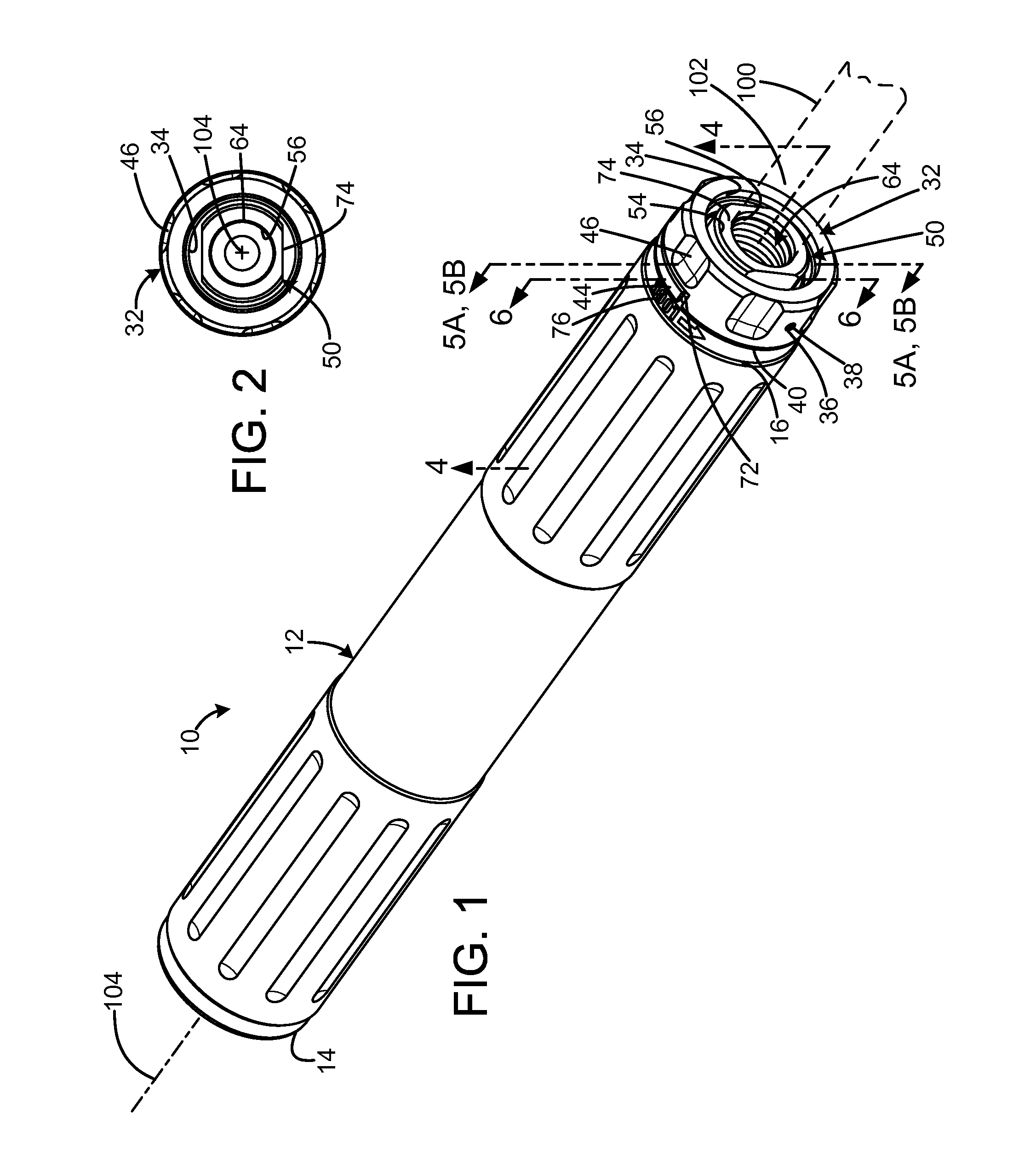

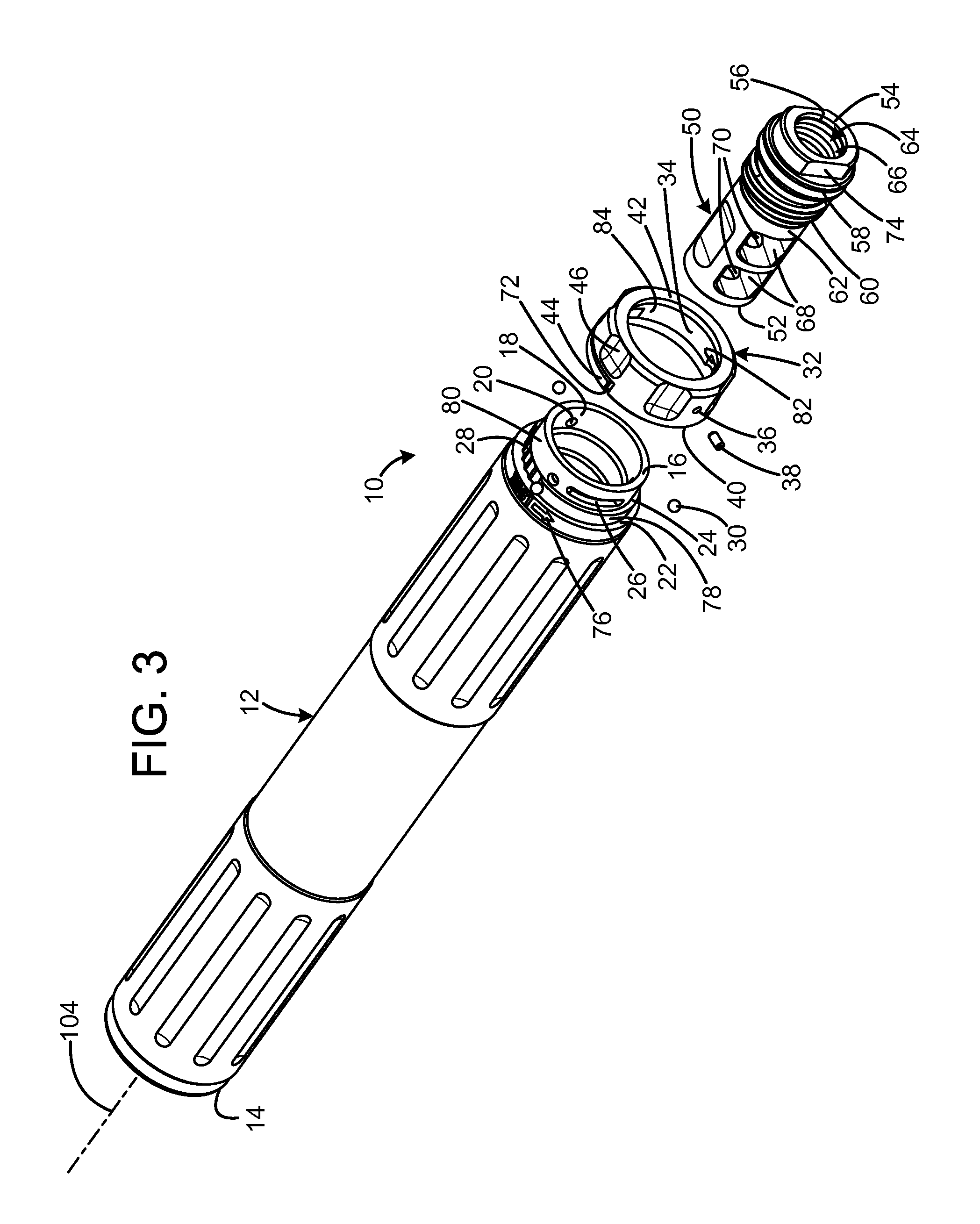

[0020]An embodiment of the firearm suppressor mounting device of the present invention is shown and generally designated by the reference numeral 10.

[0021]FIGS. 1-3 illustrate the improved firearm suppressor mounting device 10 of the present invention. More particularly, the mounting device includes a suppressor body 12, locking ring 32, and muzzle adapter 50. The body is an elongated cylindrical tube with a front 14, a rear 16, and a central bore 18. The rear of the body has a series of annular features 78, 80 having progressively smaller exterior diameters that are separated by shoulders 22, 24. The annular feature 78 includes a plurality of detents 28 on its exterior, with the remaining portion of the exterior being smooth. The annular feature 80 defines a pin slot 26 and a plurality of apertures 20 that communicate with the central bore 18. In the current embodiment, the pin slot has a length that is approximately ⅙ of the circumference of the annular feature 80, and preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com