Heat Exchanger

a heat exchanger and heat exchange technology, applied in the field of heat exchangers, can solve the problems of deteriorating heat exchange efficiency and frost formation, and achieve the effects of enhancing the bending rigidity of the whole heat exchanger, facilitating heat exchange between air and coolant, and enhancing the heat exchange efficiency of the heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In the following, it will be explained about the embodiments of the present invention referring to the associated figures.

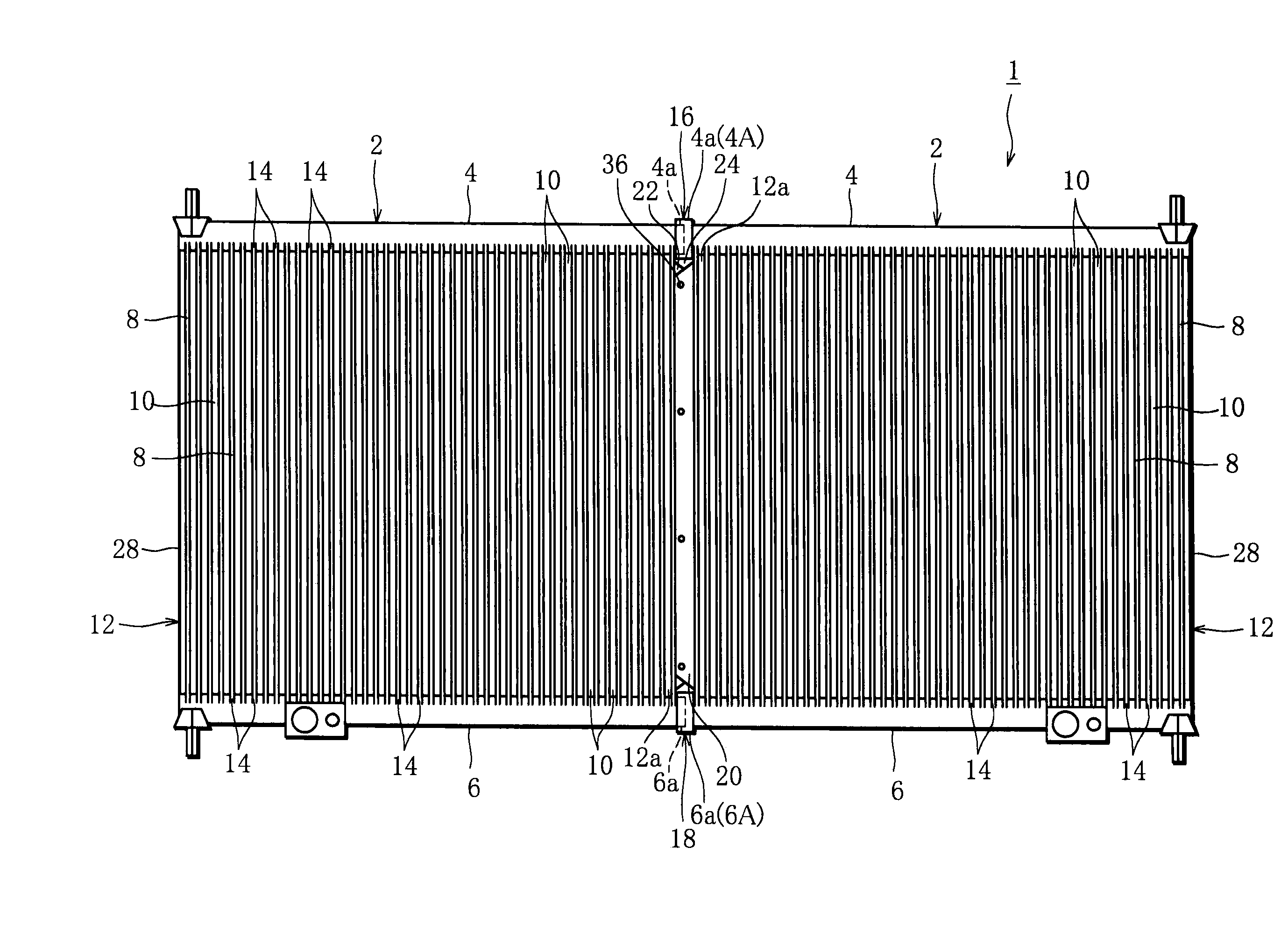

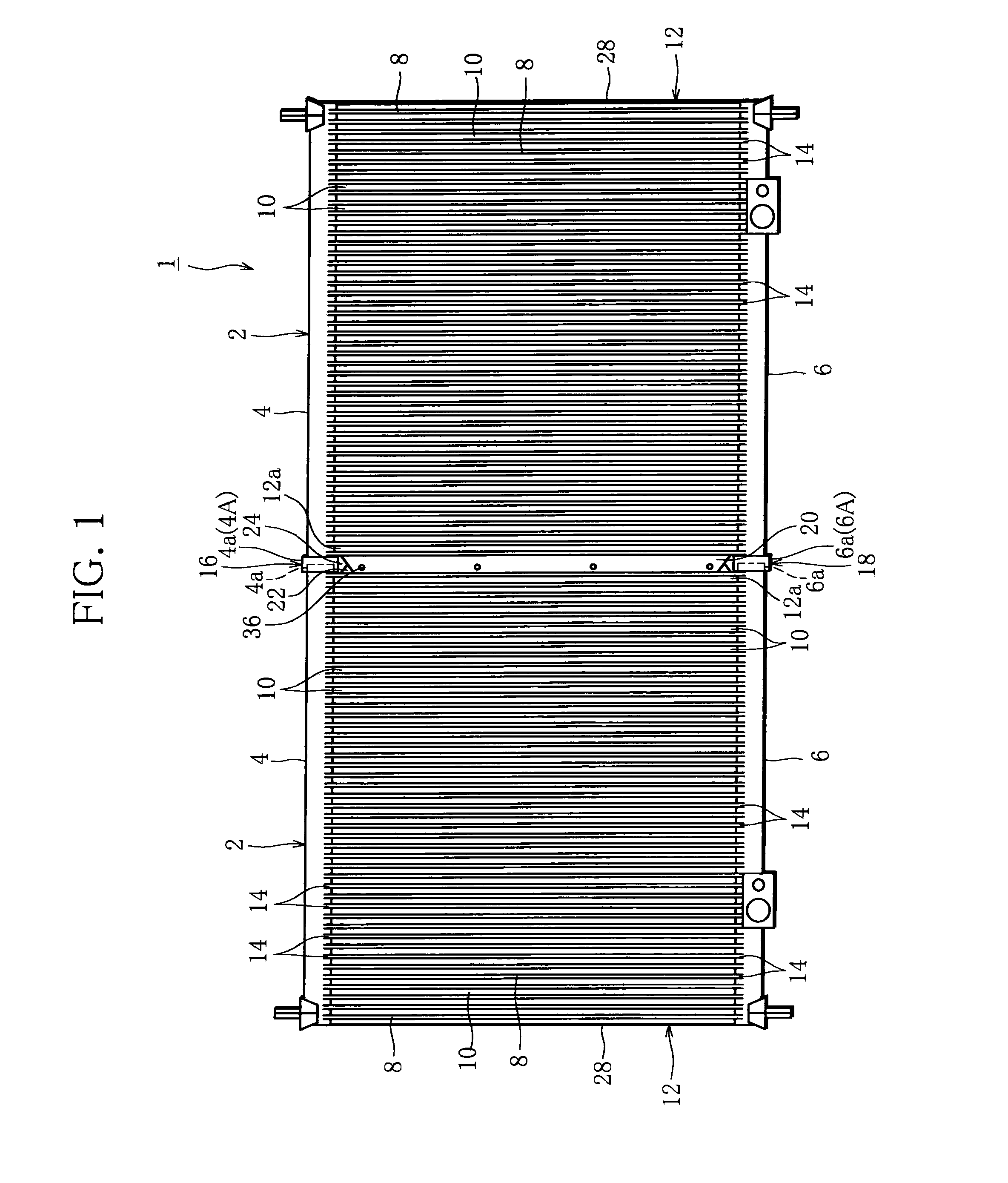

[0035]FIG. 1 is a front view of the heat exchanger 1 of an embodiment according to the present invention. The heat exchanger 1 is of a vertical-coolant-flow type, and is configured with two heat exchanger units 2 being arranged in parallel in the lateral direction.

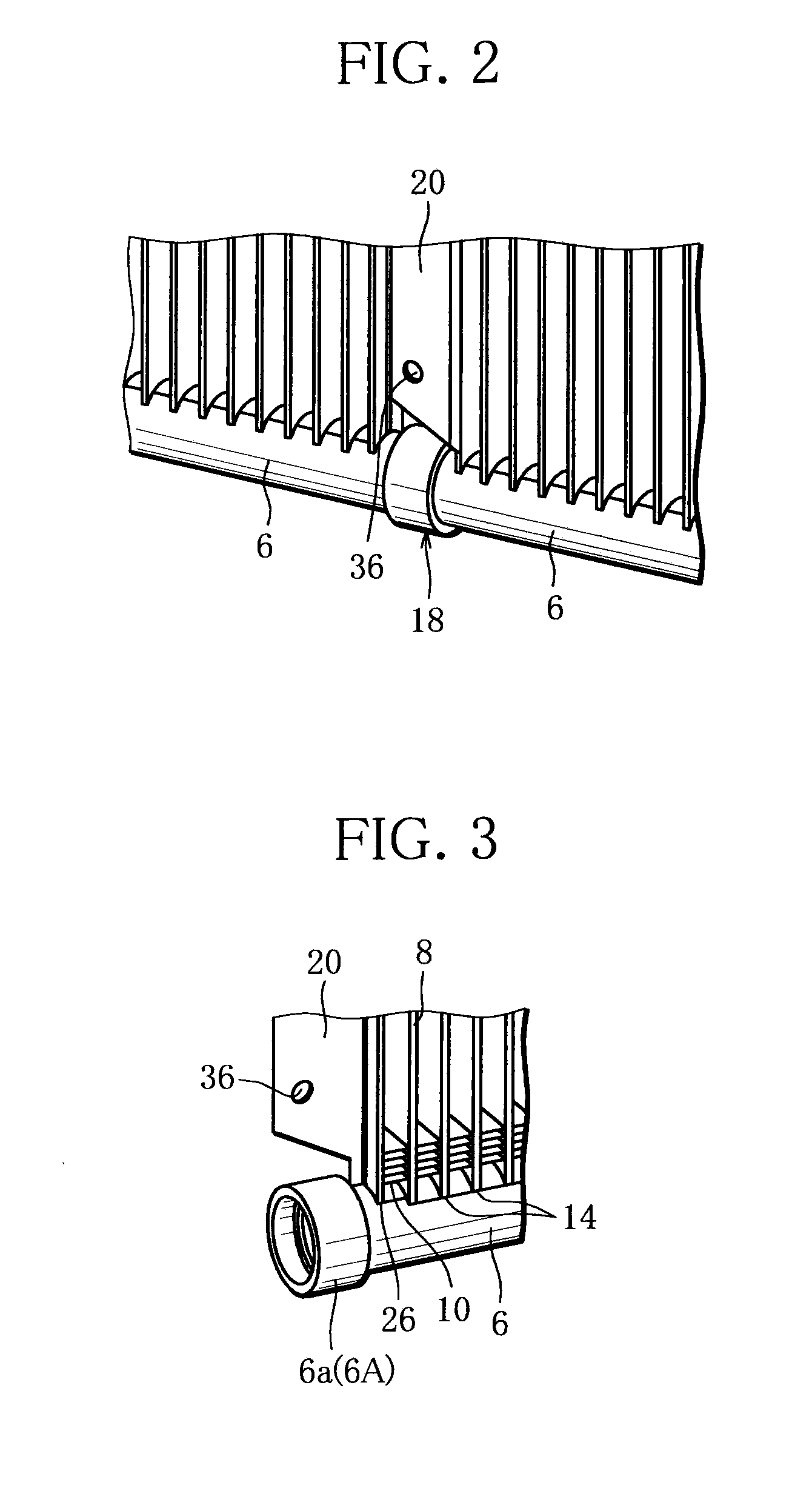

[0036]The heat exchanger unit 2 comprises upper- and lower header pipes 4, 6 disposed in parallel to each other extending in lateral direction, a plurality of tubes communicating with both header pipes 4,6 and being disposed parallel to each other with a small distance in between the header pipes 4,6, and fins 10 disposed between adjacent tubes 8. These tubes 8 and fines 10 that are layered constitute a core portion of the heat exchanger. The plurality of tubes 8 are connected by blazing at the connecting holes that are provided in regular intervals on the header pipes 4,6.

[0037]FIG. 2 shows an en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com