Beverage Bottle with Storage Solutes

a technology of beverage bottles and solutes, which is applied in the field of beverage bottles with storage solutes, can solve the problems of not only costing more resources, increasing production costs, and not achieving the purpose of keeping it fresh, and achieves the effect of reducing the effect of membranes, releasing quickly and completely, and good cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

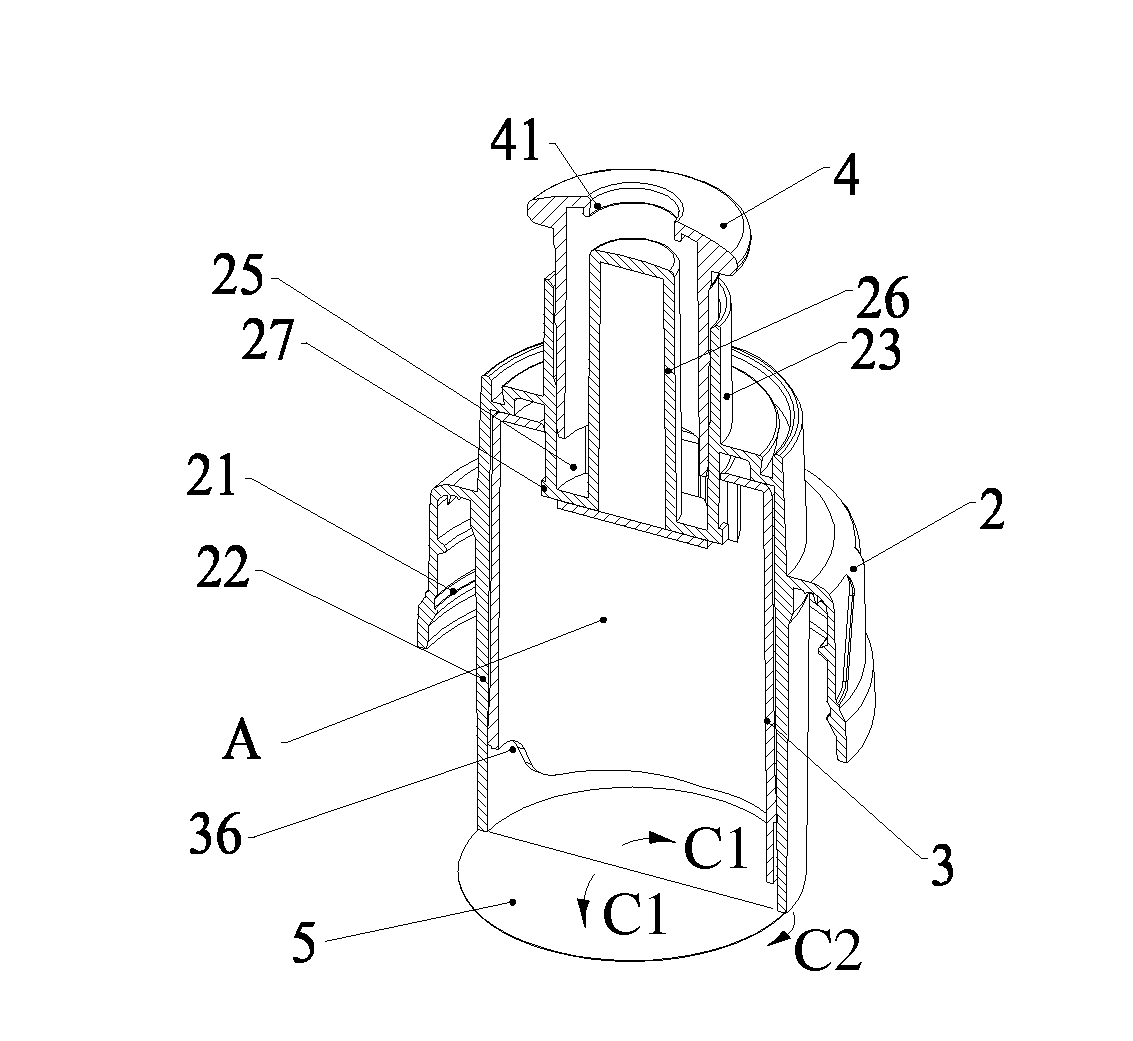

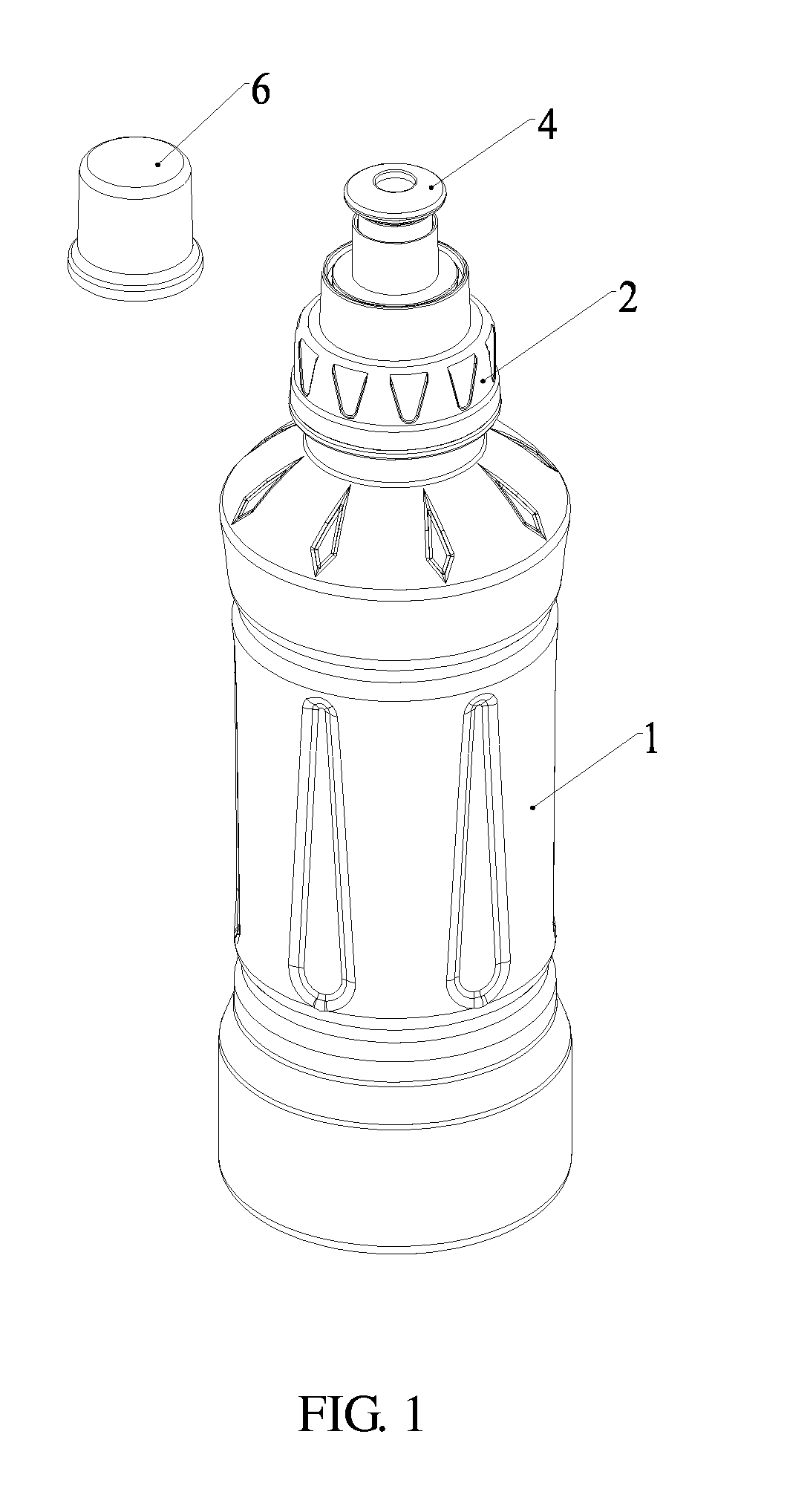

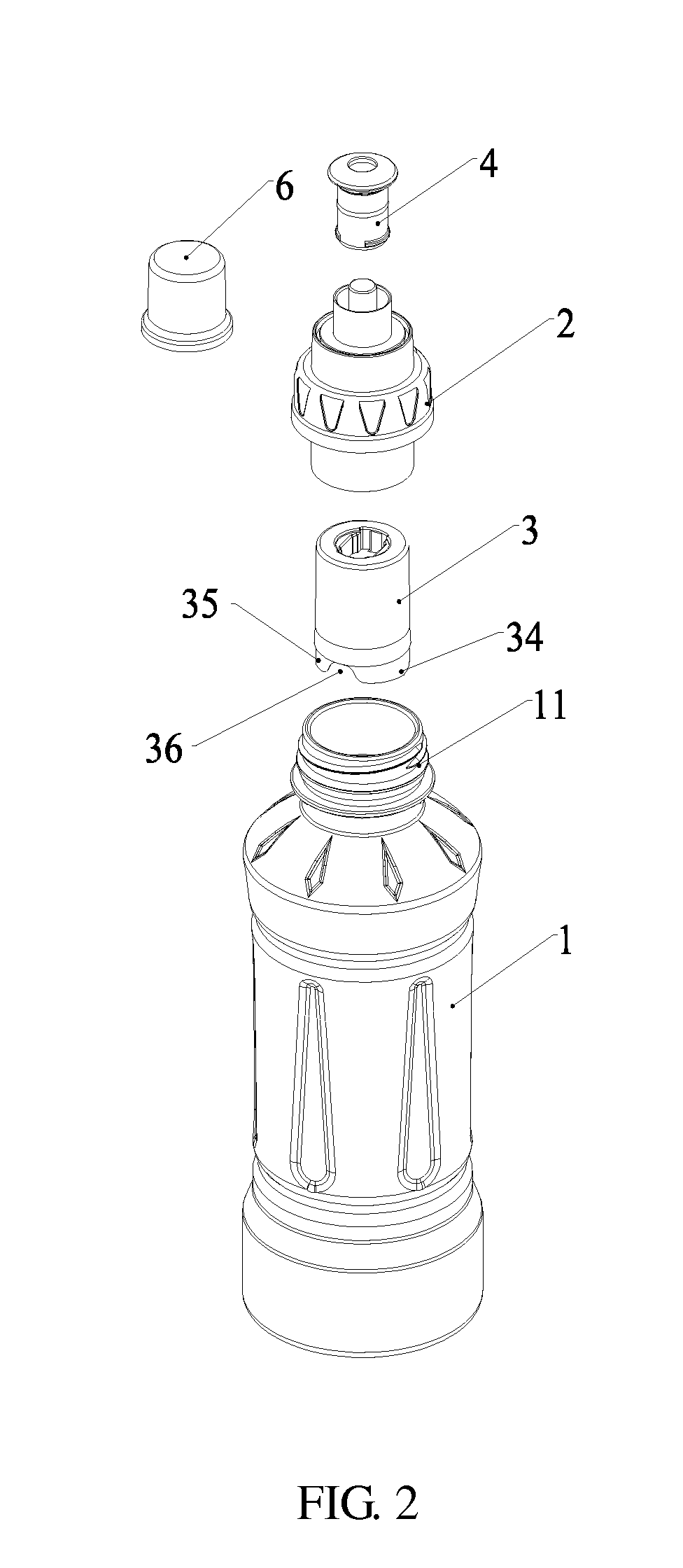

[0027]Referring to FIG. 1 to FIG. 10, according to an embodiment, the present invention provides a beverage bottle with storage solutes, which includes a bottle body 1 and a bottle cap, the bottle cap including a bottle cap body 2, a cutting membrane inner cylinder 3 and a drinking pumping cylinder 4; the bottle cap body has a screwing portion 21, an inner cylinder portion 22, a sleeve 23, a base plate 24, a water outlet cylinder portion 25 and a central spindle 26, all of which are integrally-formed; the screwing portion connects with a bottle nozzle 11 of the bottle body by spinning; a membrane 5 being disposed on the lower tail end of the inner cylinder portion, the membrane and the cutting membrane inner cylinder (3) constitute a space A for storing solutes; the drinking pumping cylinder is disposed inside the sleeve, and the base plate is provided for restricting the move down position of the drinking pumping cylinder; the cutting membrane inner cylinder has an inner sleeve 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com