Analyte sensors having a signal-to-noise ratio substantially unaffected by non-constant noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

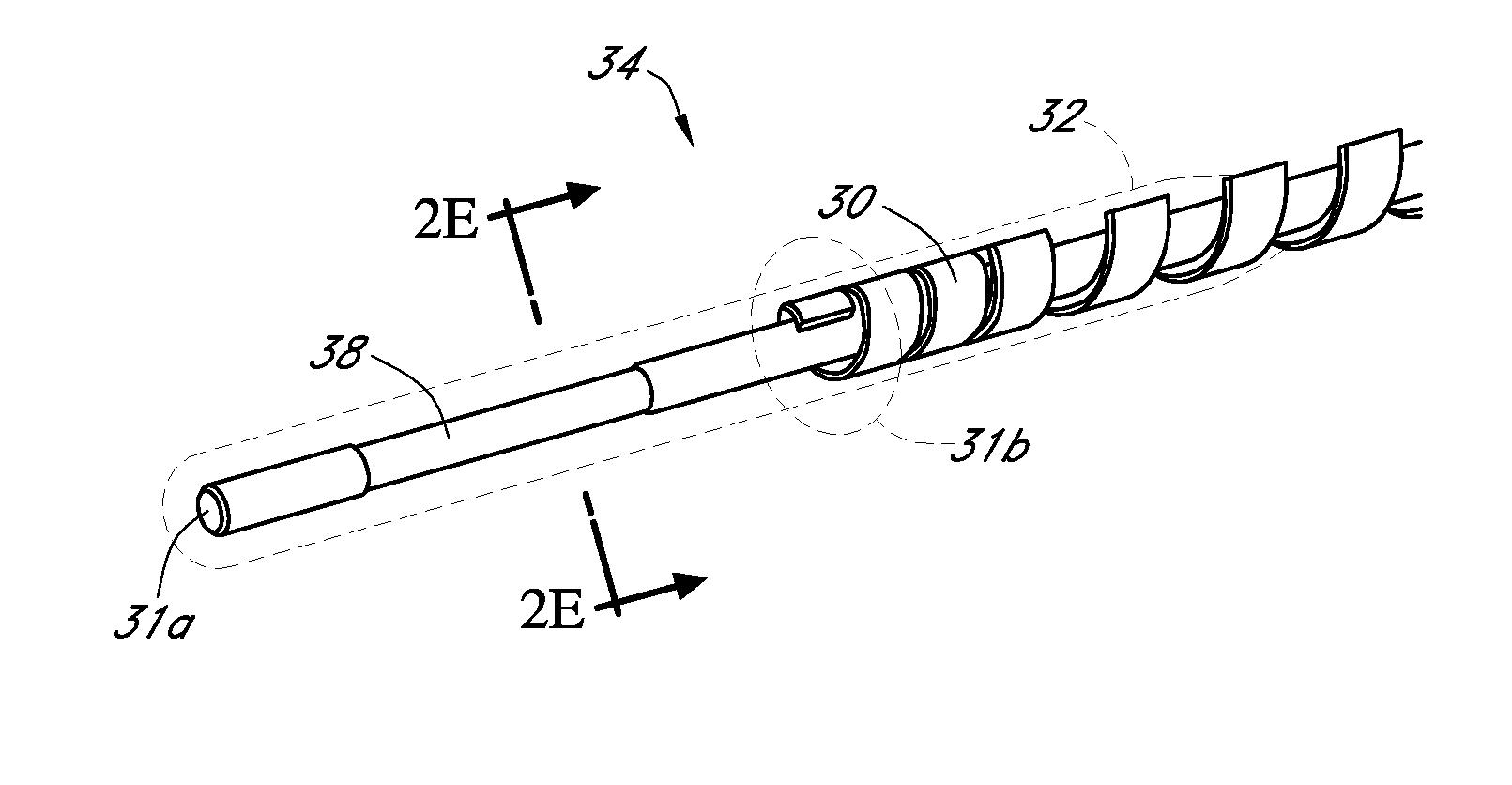

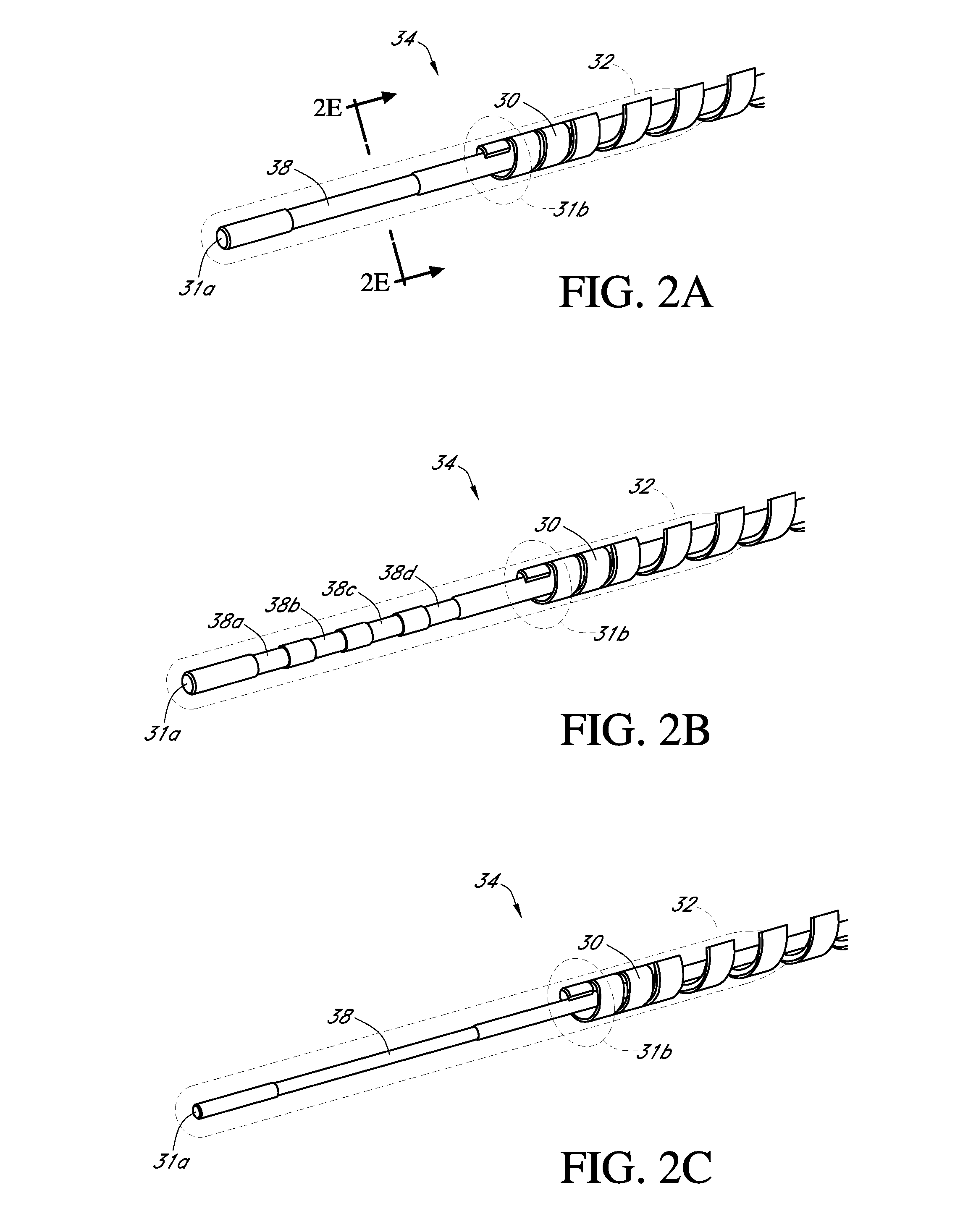

Image

Examples

example 1

Resistance Domain Configurations to Increased the Analyte Signal Reduce Non-Constant Noise

[0412]Transcutaneous sensors, with electrode, interference, enzyme and resistance (polyurethane blend) domains, were built and tested in non-diabetic hosts. The control and test sensors were built as described in U.S. Publication No. 2006-0020187, which is incorporated herein by reference in its entirety, with the following exception: the resistance domain of the test sensors was formed of 3 layers of a 60% ChronoThane® H (CardioTech International, Wilmington, Mass., USA; the PEO concentration of ChronoThane® H is about 25%) polyurethane blend solution, as compared to a single layer of a 45% ChronoThane® H polyurethane blend solution in the control sensors. Test and control sensors were implanted bilaterally in the abdomens of non-diabetic host volunteers, for a period of about 7 days.

[0413]FIG. 8 illustrates exemplary test results from one test sensor, over a period of about 7 days, after sens...

example 2

A Lubricious Coating Configured to Reduce Non-Constant Noise

[0416]Control and test sensors, with electrode, enzyme and resistance domains, were built as described in U.S. Patent Publication No. US-2006-0020187-A1, including a resistance domain formed using a polyurethane polymer blend having about 8 wt. % PEO, as described in the section entitled “Polyurethane Polymer Material” above. A lubricious coating was applied to the test sensors by dipping them one time into a solution of HydroMed™ (CardioTech International, Inc., Wilmington, Mass., USA) and drying. The control and test sensors were tested in vitro (see Table 1, below). The test sensors (with the lubricious coating) had a substantially increased sensitivity (m) but with no corresponding increase in constant noise (b), when compared to control sensors (no lubricious coating). Accordingly, it was shown that application of a lubricious coating over a polyurethane blend resistance domain of a glucose sensor can (in vitro) substa...

example 3

Discontinuous Hydrophilic Overcoat on Resistance Domain Configured to Reduce Non-Constant Noise

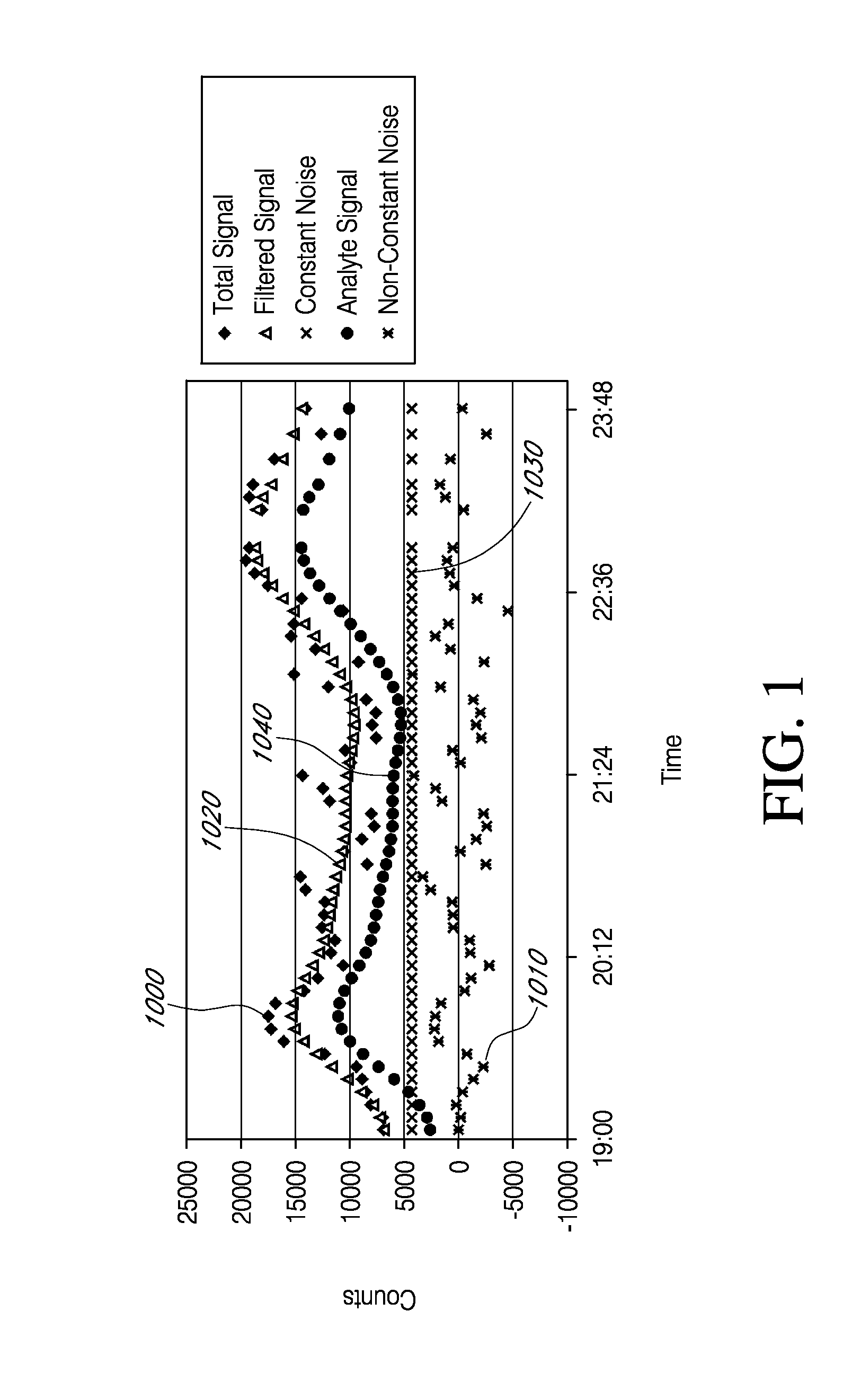

[0418]To determine if a hydrophilic overcoat on the resistance layer can increase the analyte signal component and / or reduce the non-constant noise component, test and control sensors were build and tested in volunteer human hosts, over a period of 3 days. Both the test and control sensors included an electrode layer, an enzyme layer and a polyurethane blend resistance domain. The polyurethane blend used to form the resistance domain included 8% hydrophile (i.e., PEO). After fabrication, the test sensors were sprayed (one time) in a solution of 5% ChronoThane® H (about 25% PEO; CardioTech International, Wilmington, Mass., USA) and cured. Test and control sensors were implanted bilaterally in the abdomens of the volunteer human hosts. FIG. 10 is a graph showing test results from one exemplary sensor. Components of the Total Signal 1000 were determined, as described in Example 1. The Y-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com