Thermoelectric energy storage system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

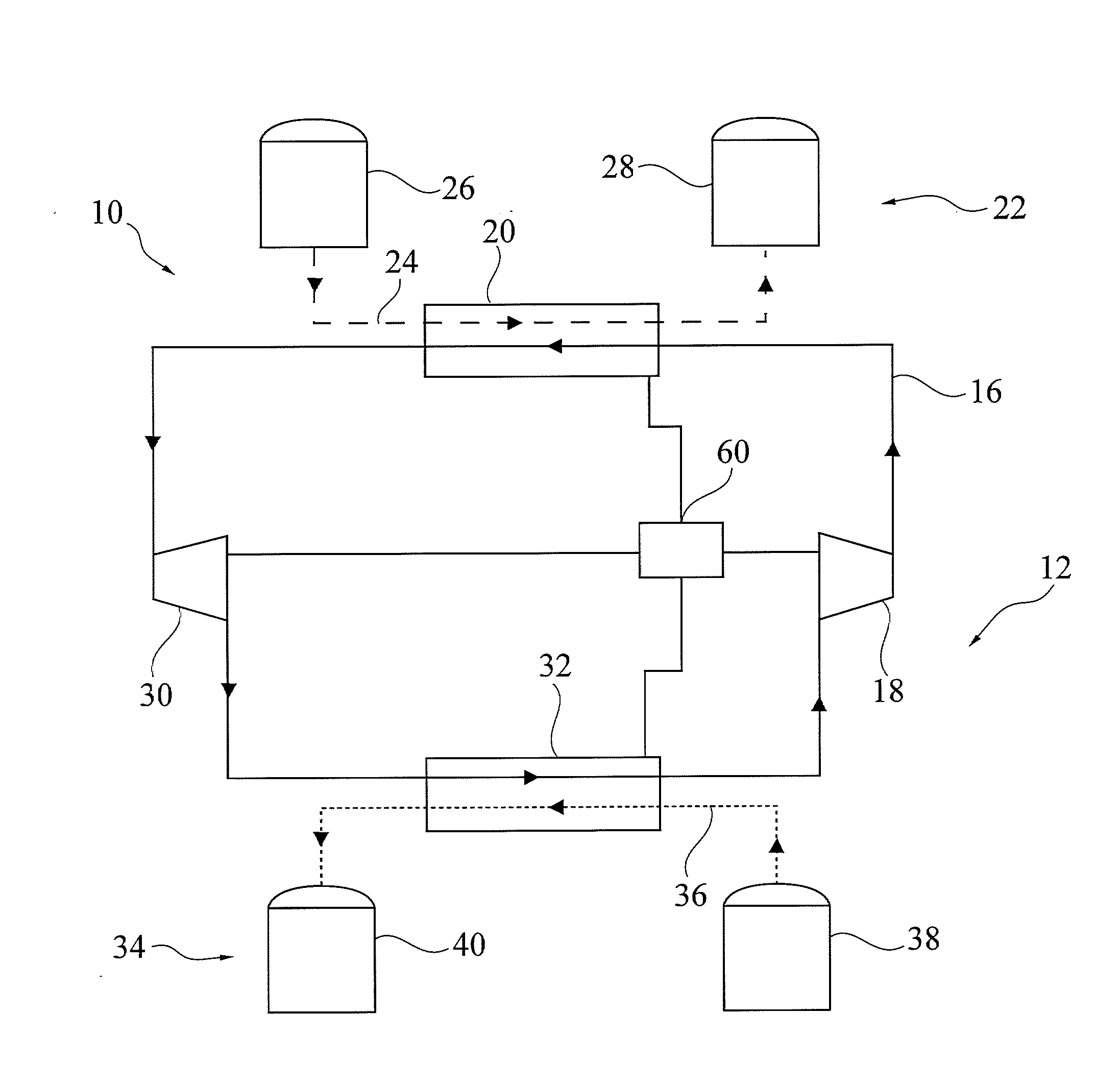

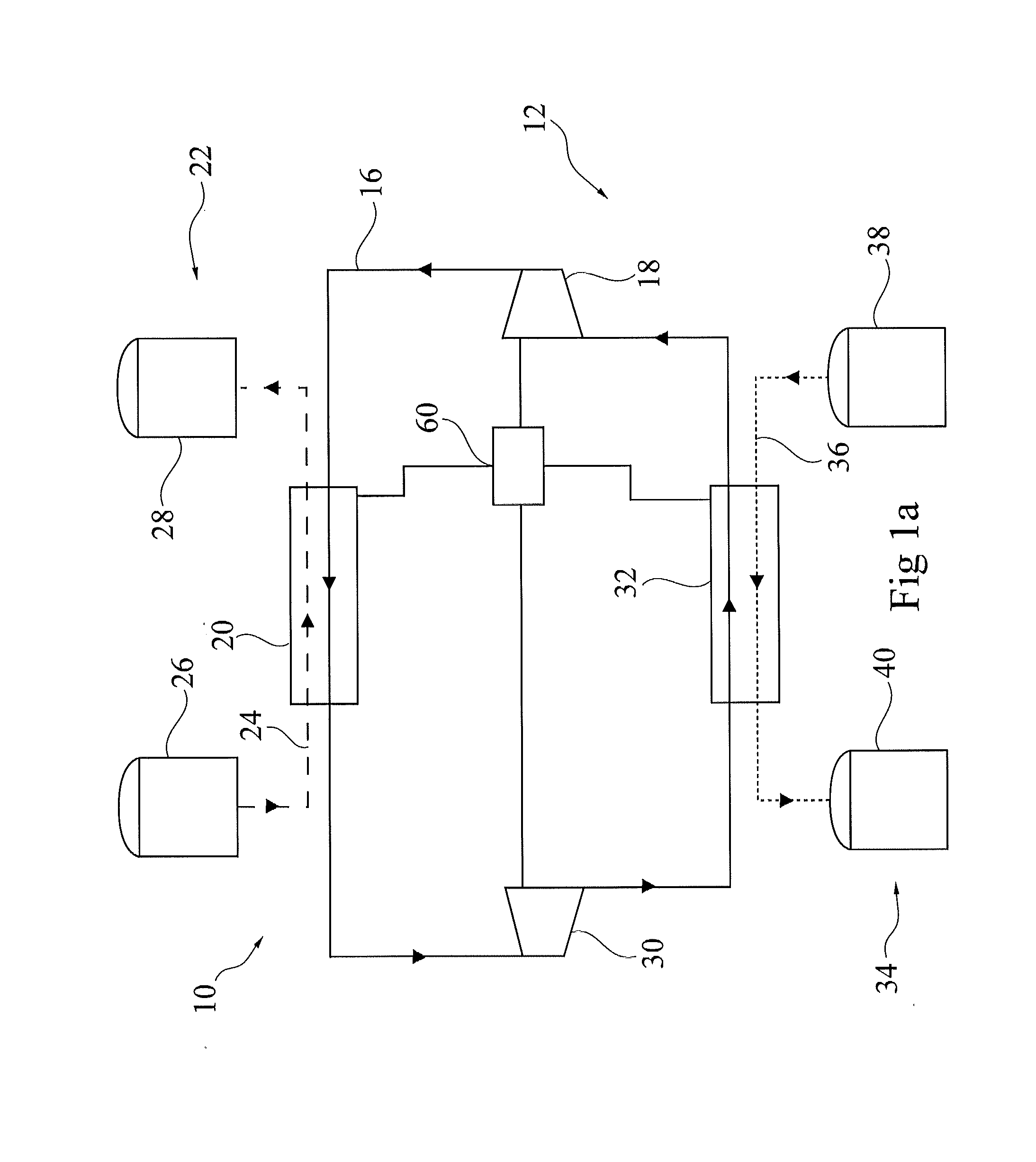

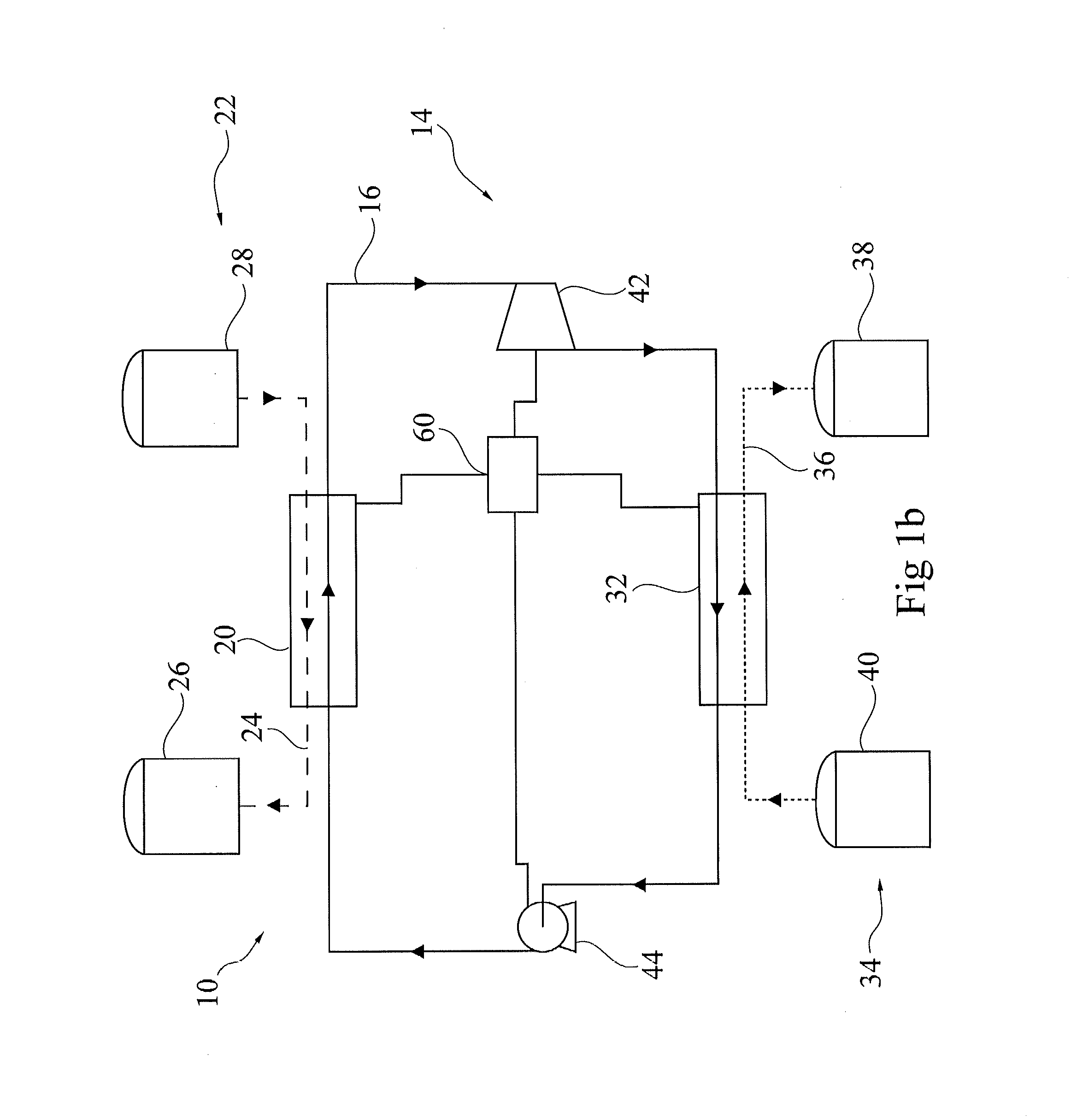

[0030]Exemplary embodiments of the present disclosure provide an efficient thermoelectric energy storage having a high round-trip efficiency and a minimal approach temperature, while minimizing the amount of required thermal storage medium, and also minimizing the cost.

[0031]An exemplary embodiment of the present disclosure provides a thermoelectric energy storage system for storing electrical energy by transferring thermal energy to a thermal storage in a charging cycle, and for generating electricity by retrieving the thermal energy from the thermal storage in a discharging cycle.

[0032]According to an exemplary embodiment of the present disclosure, the thermoelectric energy storage system includes a working fluid circuit configured to circulate a working fluid through a heat exchanger, and a thermal storage conduit configured to transfer a thermal storage medium from a thermal storage tank through the heat exchanger. The working fluid includes a zeotropic mixture.

[0033]In other wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com