Salient-pole type linear motor and reciprocal double piston compressor with salient-pole type linear motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

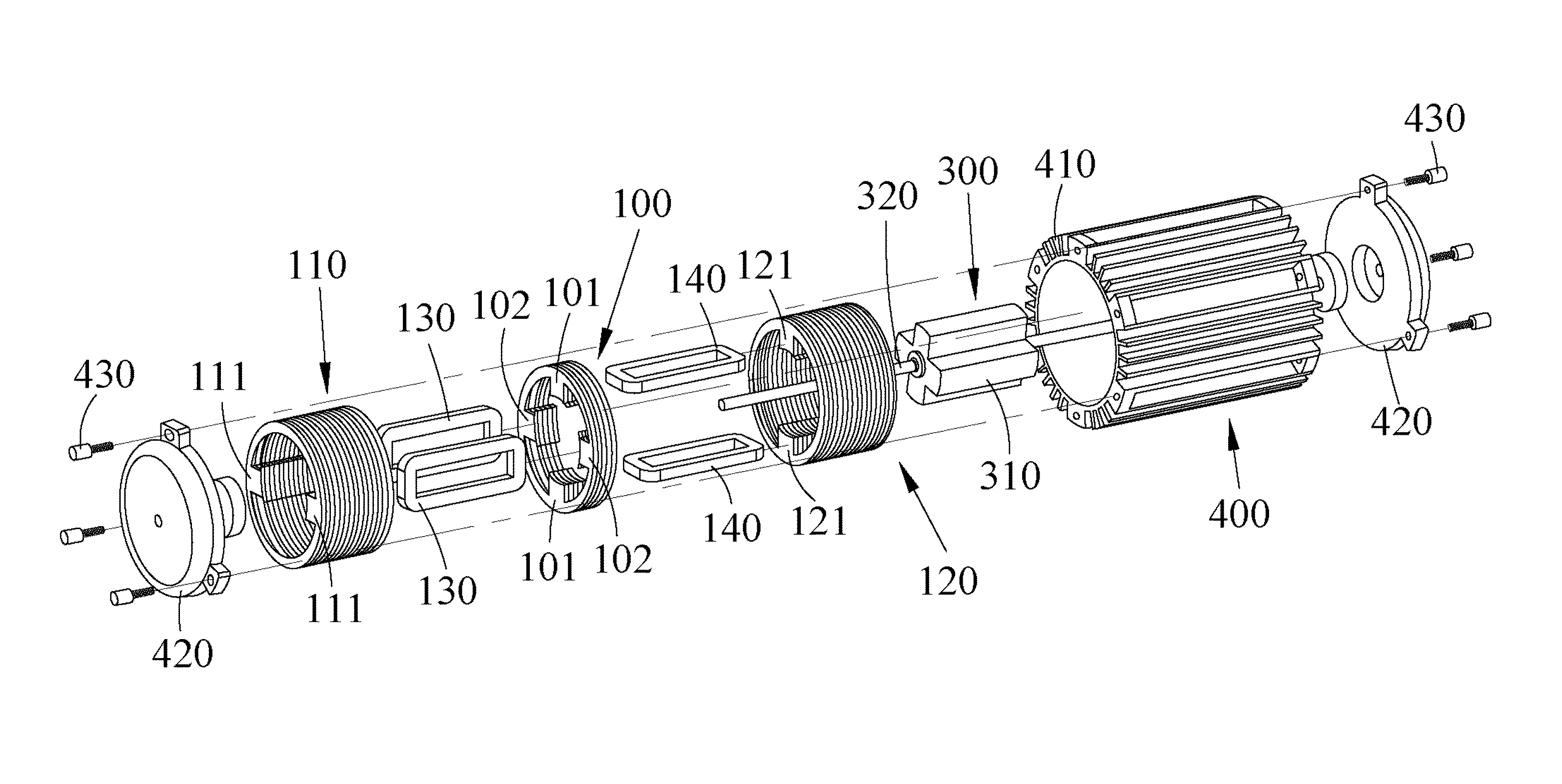

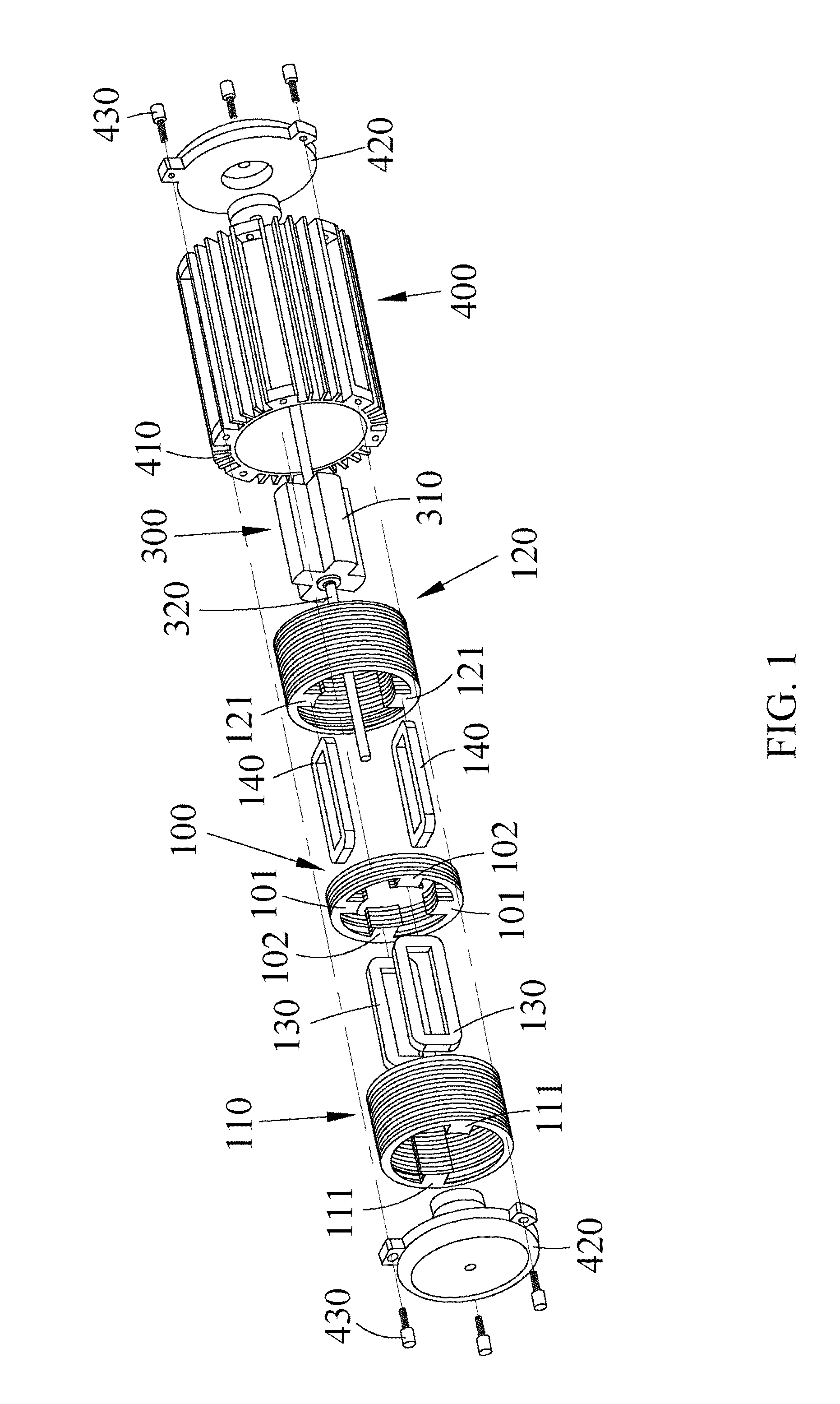

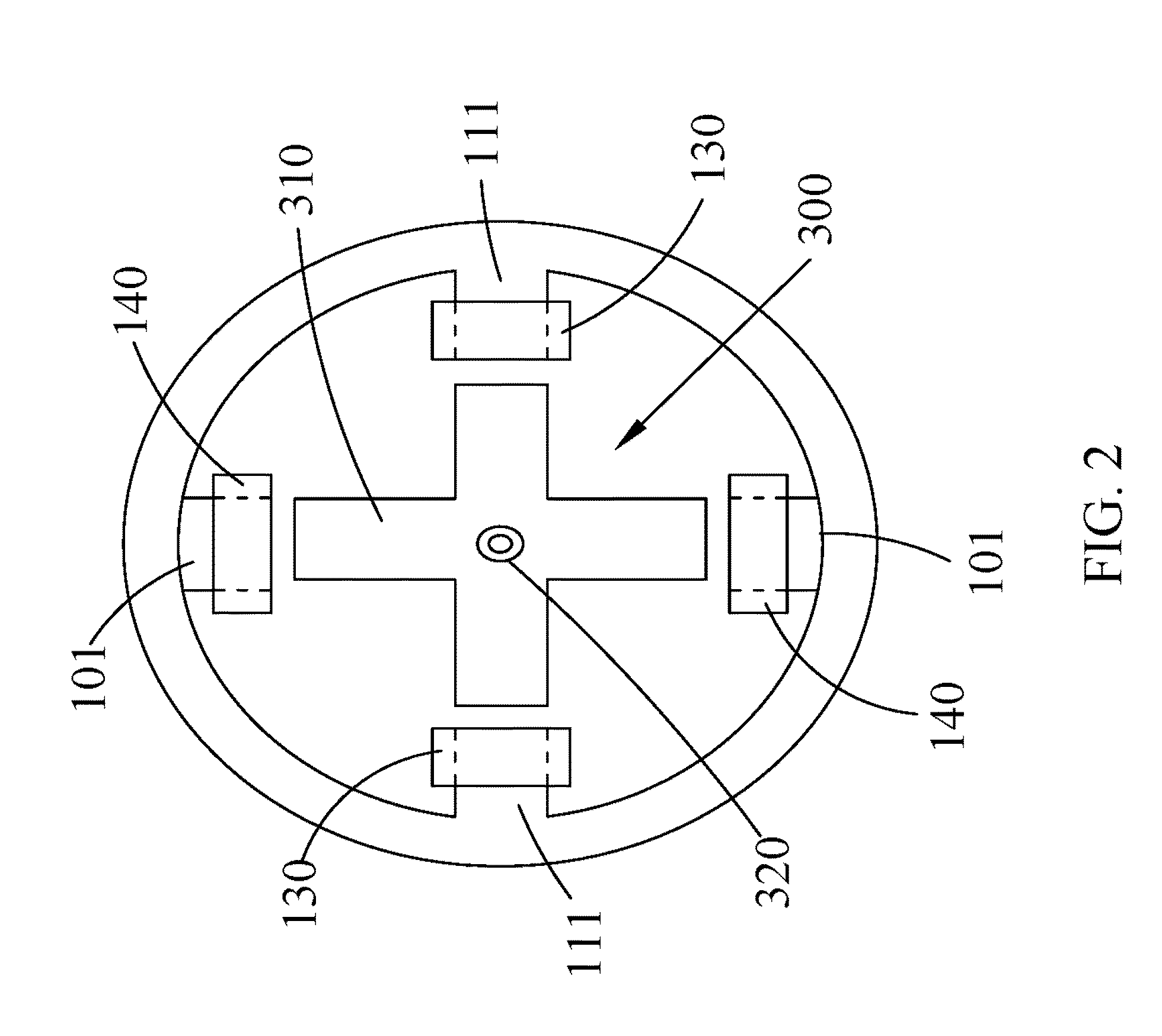

[0033]The technical characteristics of the present invention will become apparent with the detailed description of the preferred embodiments accompanied with the illustration of related drawings as follows. It is noteworthy that same numerals are used for representing the same respective elements in the drawings, and the drawings are provided for the purpose of illustrating the invention, but not intended for limiting the scope of the invention.

[0034]In a salient-pole type linear motor of the present invention, magnetic poles of front and rear stator cores are disposed on a stator, and a coil is formed on the magnetic pole, such that a magnetic field produced by the front and rear coils will go through a path with a minimum magnetic reluctance by sealing the magnetic lines of force, such that the mover will be moved in a direction towards the minimum magnetic reluctance, so as to constitute the salient-pole type linear motor of a linear motion. In addition, the salient-pole type lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com