Processes for preparing amines and catalysts for use therein

a technology of amines and catalysts, which is applied in the preparation of amino compounds, physical/chemical process catalysts, metal/metal-oxide/metal-hydroxide catalysts, etc., can solve problems such as “runaway risks” and problems in product quality, and achieve high conversion, high yield, and improved economic viability of existing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

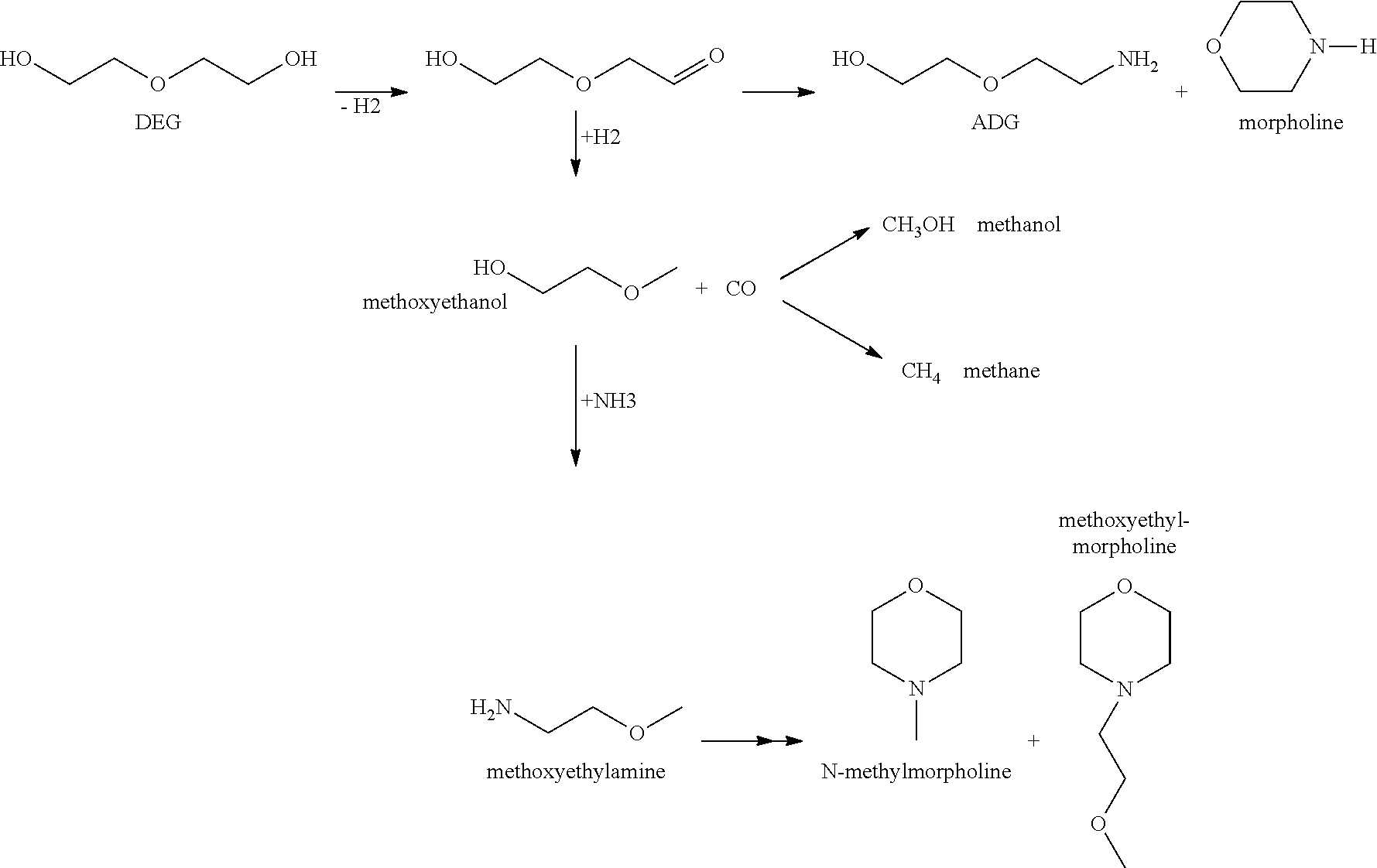

Method used

Image

Examples

example 1

Preparation of Amination Catalyst 1 (Based on Ni—Co—Cu / Zro2=Comparative Experiment According to EP-A-963 975)

[0162]An aqueous solution of nickel nitrate, cobalt nitrate, copper nitrate and zirconium acetate which comprised 2.39% by weight of NiO, 2.39% by weight of CoO, 0.94% by weight of CuO and 2.82% by weight of ZrO2 was precipitated simultaneously in a stirred vessel in a constant stream with a 20% aqueous sodium carbonate solution at a temperature of 70° C. in such a way that the pH, measured with a glass electrode, of 7.0 was maintained. The resulting suspension was filtered and the filtercake was washed with demineralized water until the electrical conductivity of the filtrate was approx. 20 μS. Thereafter, the filtercake was dried at a temperature of 150° C. in a drying cabinet or a spray dryer. The hydroxide-carbonate mixture obtained in this way was then heat-treated at a temperature of from 450 to 500° C. over a period of 4 hours. The catalyst thus prepared had the compos...

example 2

[0163]The catalyst was prepared analogously to catalyst 1. However, the amount of nickel nitrate and cobalt nitrate was changed accordingly. In addition, ammonium sulfate was incorporated into the still-moist filter cake, so as to obtain the oxide mixture specified below.

[0164]The catalyst thus obtained had the composition as shown in Table I.

example 3

[0165]The catalyst was prepared analogously to catalyst 2. However, the amount of nickel nitrate and cobalt nitrate was changed accordingly. In addition, ammonium dihydrogenphosphate was incorporated into the still-moist filtercake, so as to obtain the oxide mixture specified below. The catalyst 3 thus obtained had the composition as shown in Table I.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar ratio | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| absolute pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com