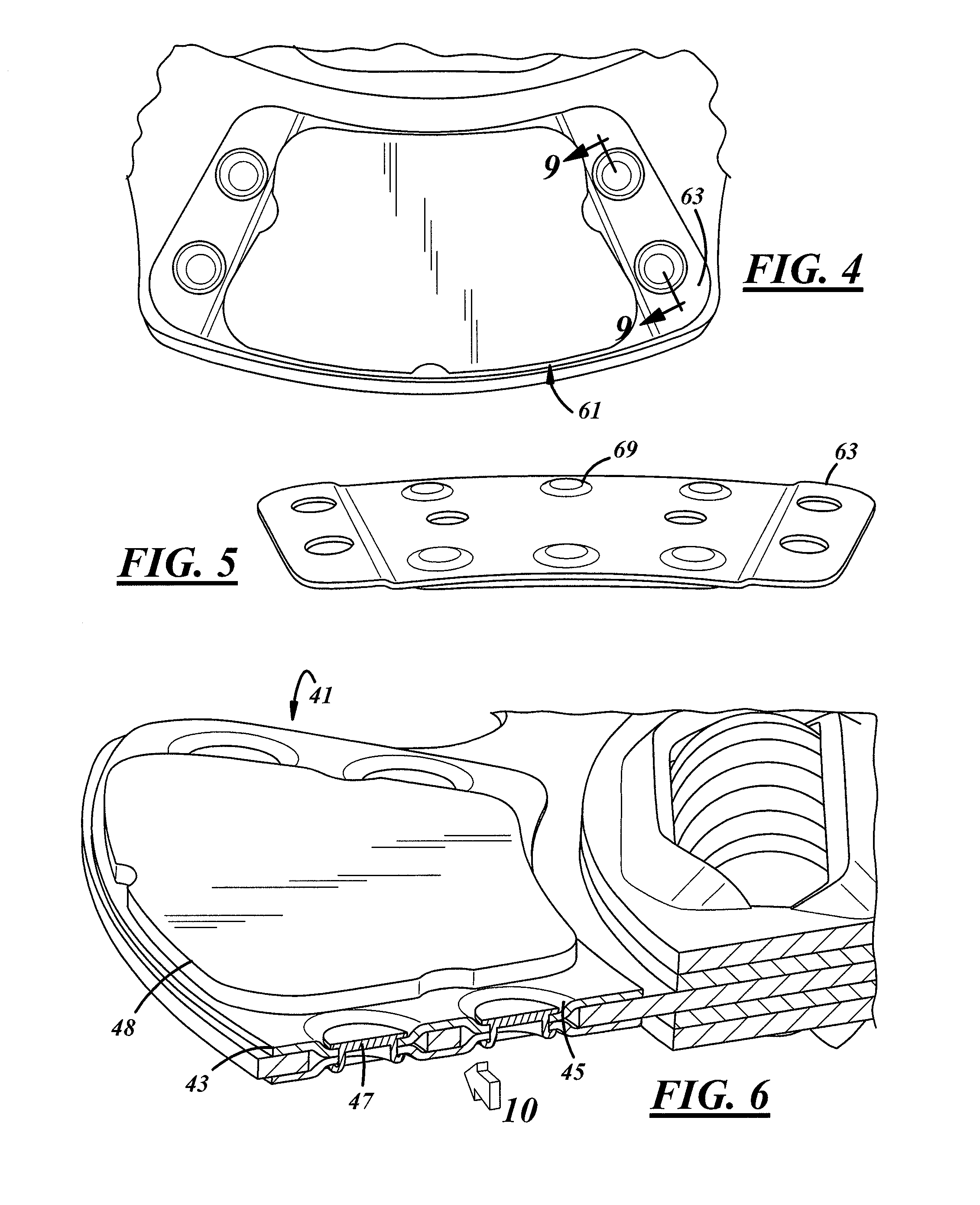

Clutch backer plate with recessed rivets

a technology of backer plate and rivet, which is applied in the direction of friction clutch, friction lining, etc., can solve the problems of increasing the high cost of the backing plate, so as to achieve the effect of reducing the thickness of the friction button and reducing the cost of the drive disc assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The following description of the preferred embodiment(s) is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

[0023]Referring to FIGS. 8 and 12, an inventive low profile button dual face clutch friction plate or disc driven assembly 107 has an overall axial width 29. The disc driven assembly 107 has a disc 111. The disc 111 has a series of mounting holes 114, which are enlarged in comparison to the mounting holes shown formed in the disc drive assembly 9 disc 11. However, in other aspects, the disc 111 is essentially identical to the disc 11. A backing plate 116 is provided which typically has a greater thickness 136 (typically a total thickness between 0.080 and 0.110 inches) than the backing plates previously described. The backing plate 116 has a mounting hole 118. Hole 118 is smaller in diameter then the disc hole 114 and is aligned therewith. The hole 118 is surrounded by a stamped semi-pierced section 120. An axially in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com