Dry blend for making extended cheese product

a technology of extended cheese and blend, which is applied in the field of extended cheese product dry blend, can solve the problems of loss of significant quantities of cheese components, process that activates the latent functional properties of certain ingredients, and difficulty in obtaining the desired concentration level of some ingredients in a cheese, and achieves excellent flexibility and reduces casein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

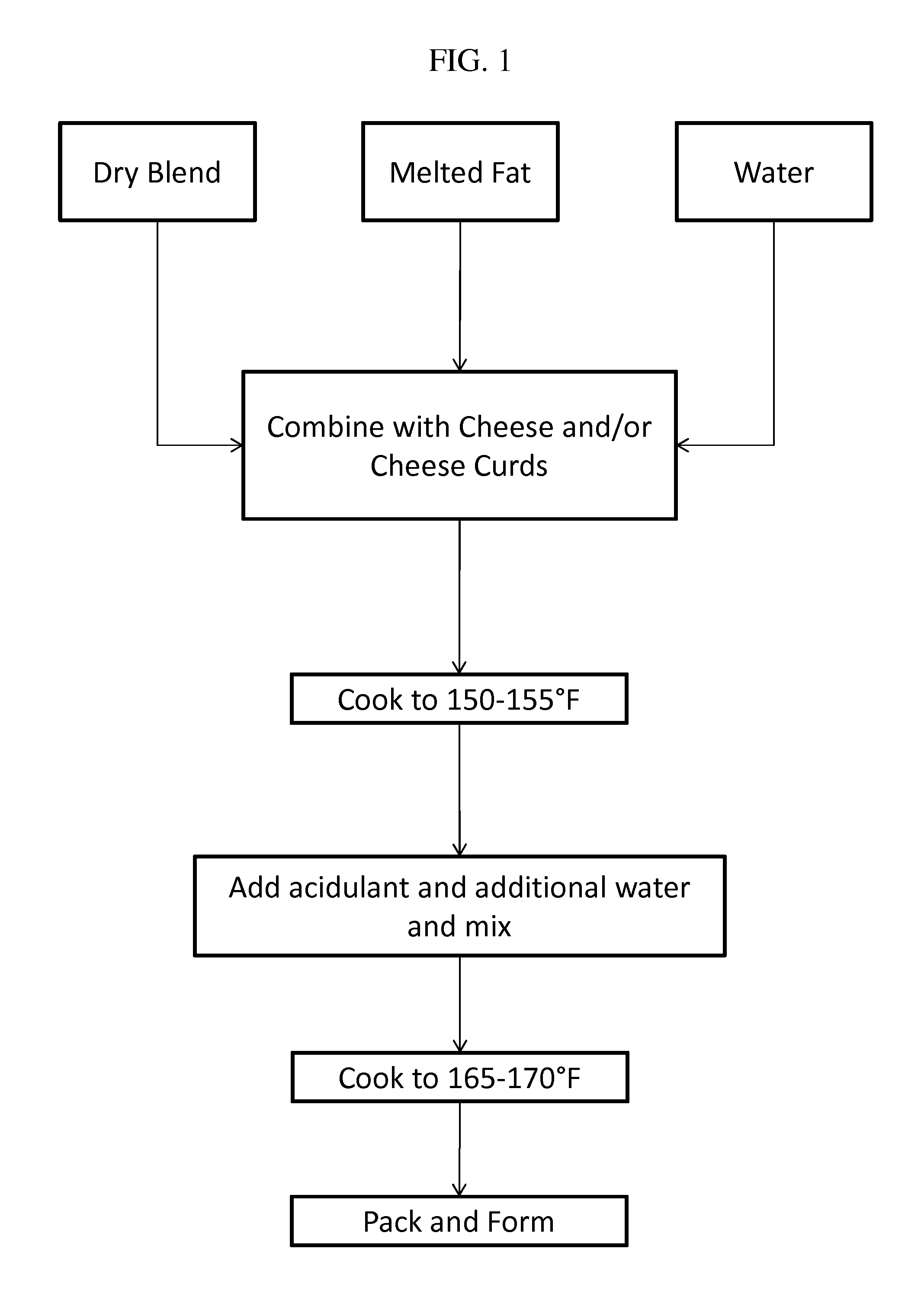

Method used

Image

Examples

Embodiment Construction

[0068]A “cheese analogue” as used herein refers generally to a cheese in which at least one milk fat and / or protein source has been replaced with a source that is not native to milk. The basic ingredients for a cheese analogue are usually water, casein, a fat / oil and a sequestering agent. Cheese analogues are typically categorized as dairy (all fats and proteins come from dairy sources), partial dairy (some fats and proteins come from dairy sources, while other have been replaced with non-dairy fats and proteins), or nondairy (all fats and proteins come from non-dairy sources). They can also be classified as being an imitation cheese or a substitute cheese. Imitation cheese is a substitute for and resembles another cheese but is nutritionally inferior to that cheese. A cheese substitute, on the other hand, resembles another cheese but is not nutritionally inferior to that cheese.

[0069]An “extended cheese product” is a food product based on a natural cheese, but wherein filler materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com