Method and system for reciprocating compressor starting

a compressor and starting system technology, applied in the direction of positive displacement liquid engine, pump parameter, instruments, etc., can solve the problem that compressors may sometimes have difficulty in starting, and achieve the effect of high starting torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

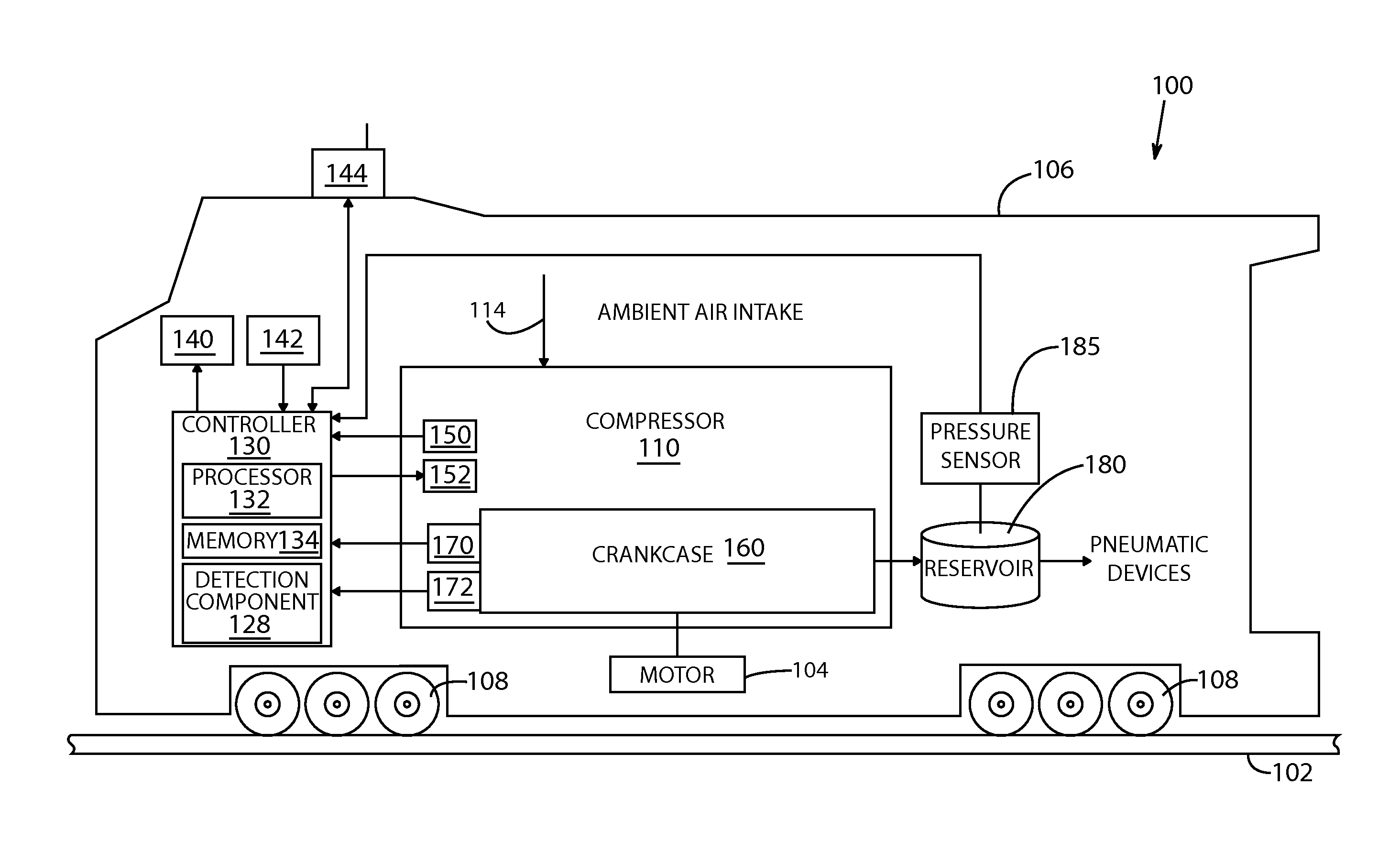

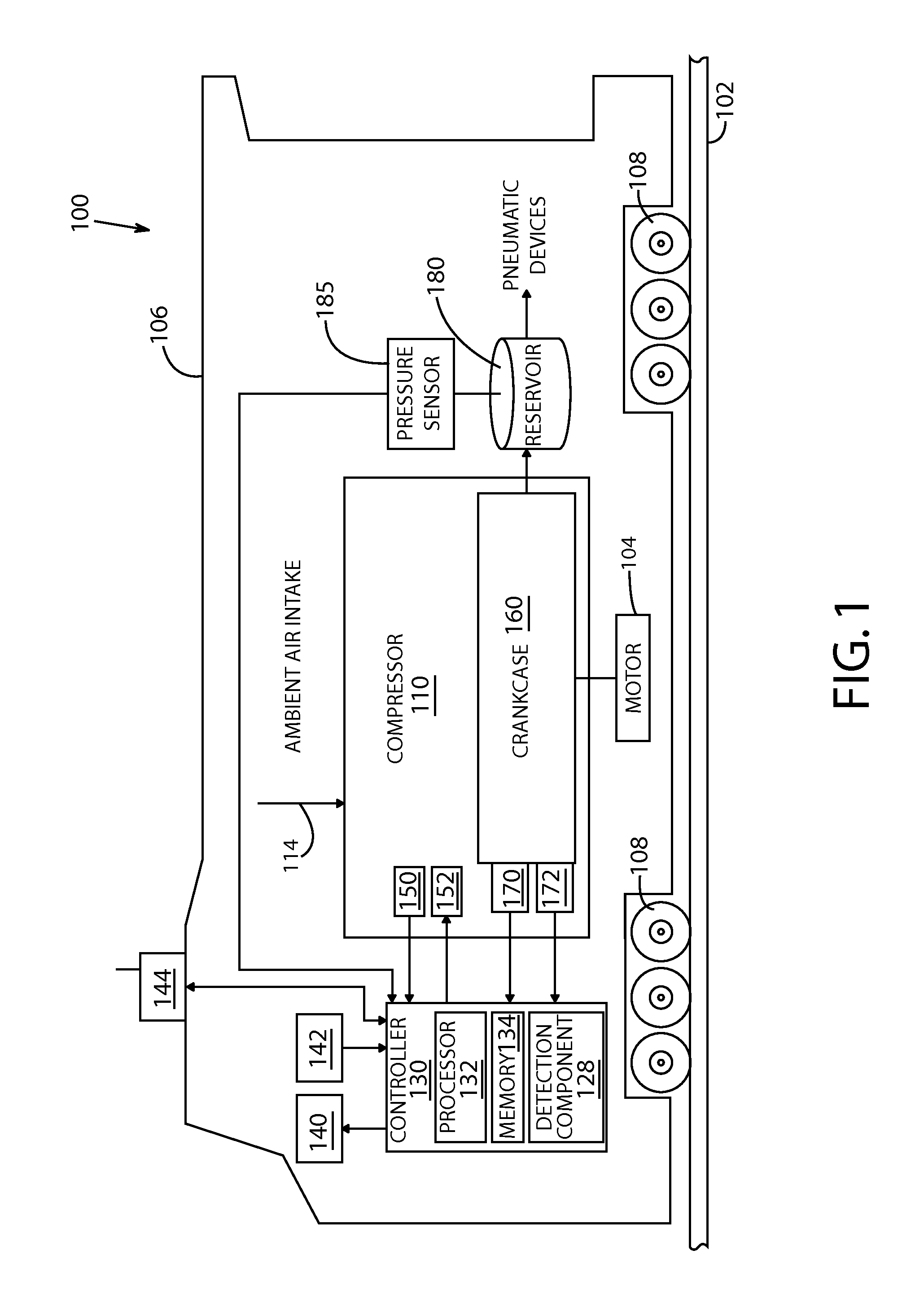

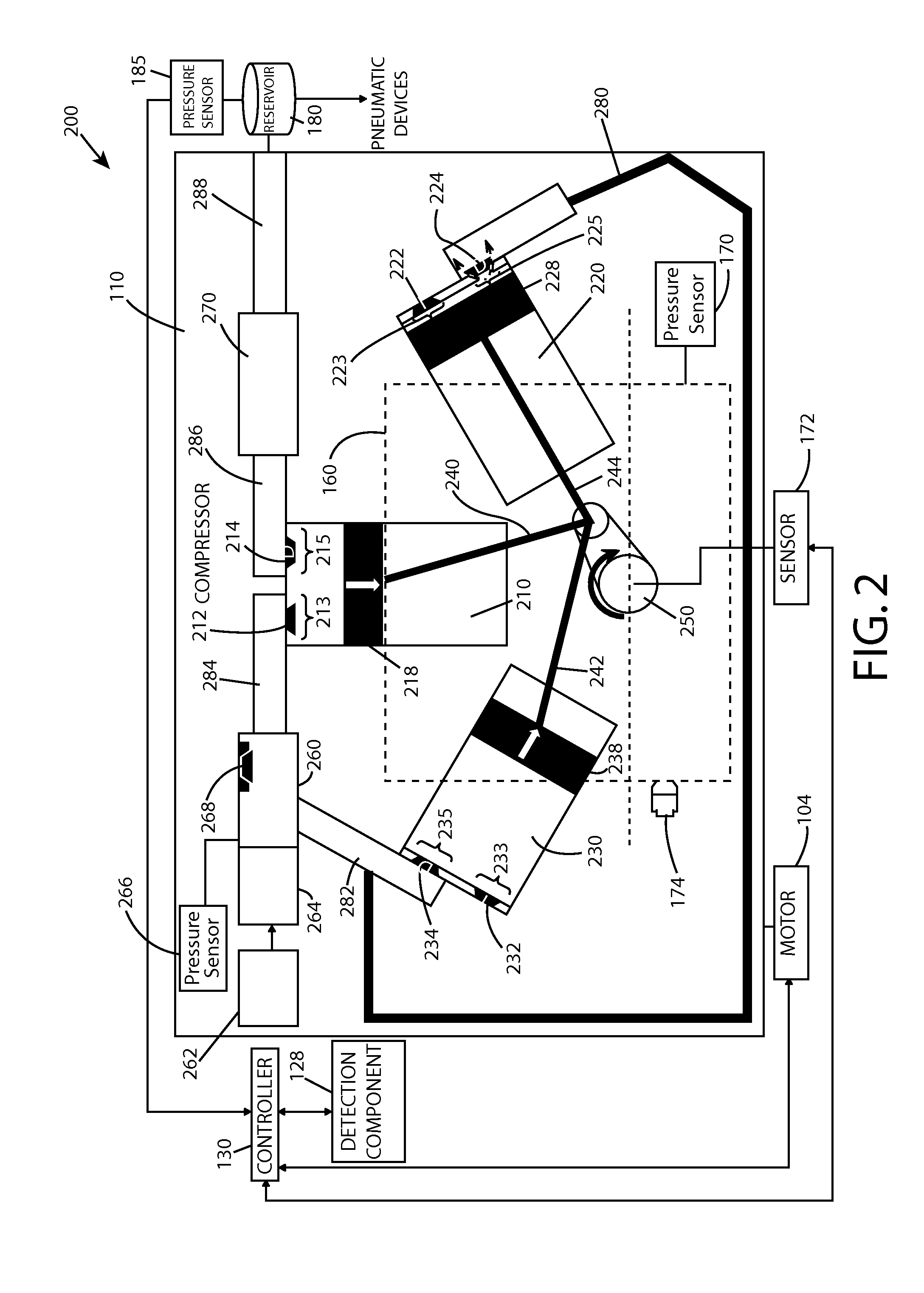

[0023]Embodiments of the subject matter disclosed herein relate to systems and methods that overcome a higher than normal starting torque for in a reciprocating, electric motor driven air compressor for a vehicle. A detection component can be configured to detect a stall condition for a reciprocating compressor based on a force from compressed air being compressed into a reservoir of the reciprocating compressor. Based upon the detected stall condition, a controller can be configured to control at least one of a reverse direction mode (also referred to as reverse phase mode) or a torque increase mode in order to alleviate the stall condition. In the reverse direction mode, the controller component can be configured to change a direction of a crankshaft rotation in order to allow a gain in momentum during a subsequent start attempt to overcome a high starting torque requirement. In the torque increase mode, the controller can be configured to increase at least one of a number of pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com