Graphene-drum pump and engine systems

a graphene-drum pump and graphene-drum technology, which is applied in the direction of machines/engines, flexible member pumps, positive displacement liquid engines, etc., can solve the problems of slow pump speed, najafi patent-fabricated microvacuum pump assembly cannot maintain a high vacuum on one side, and requires a relatively high voltage to opera

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

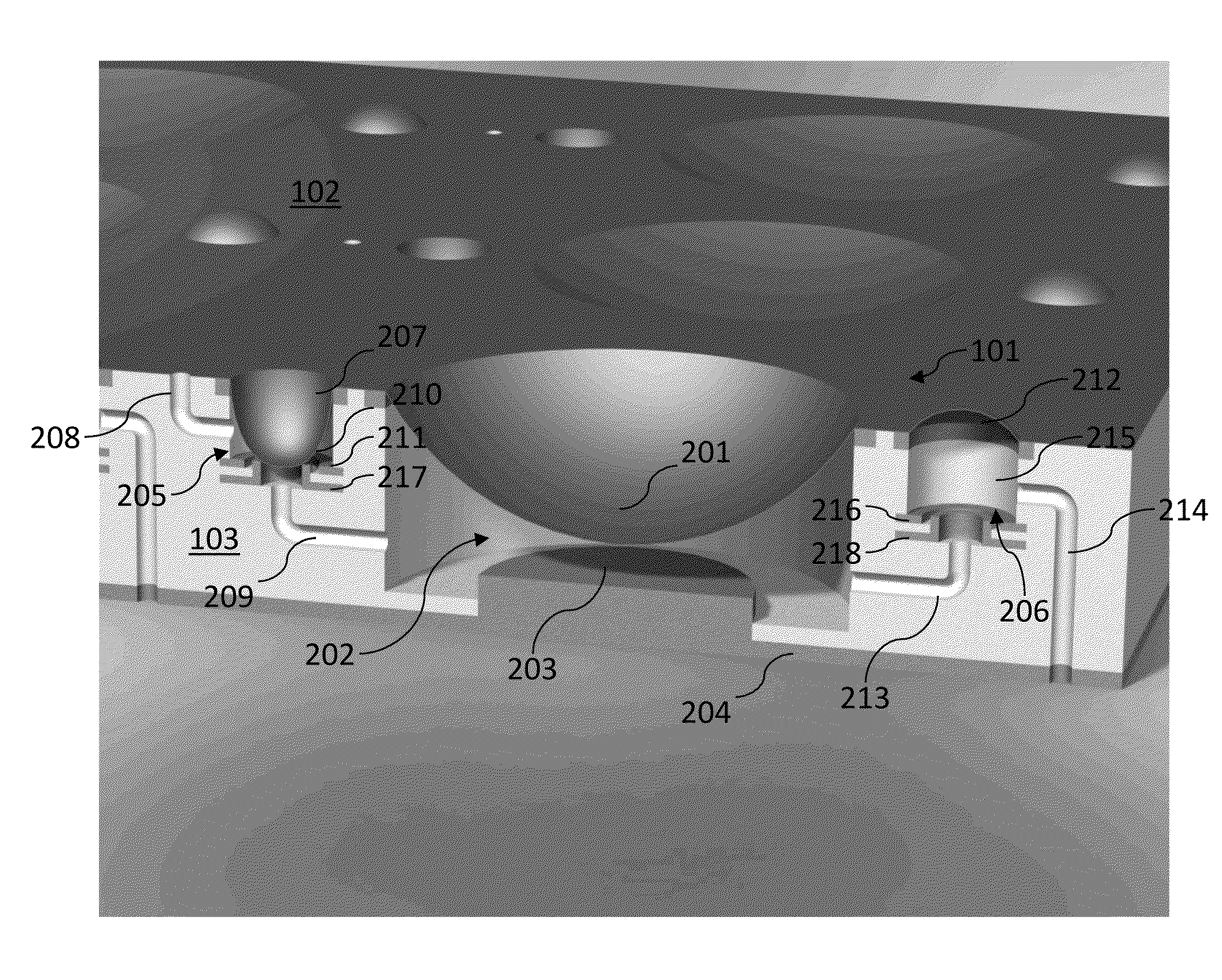

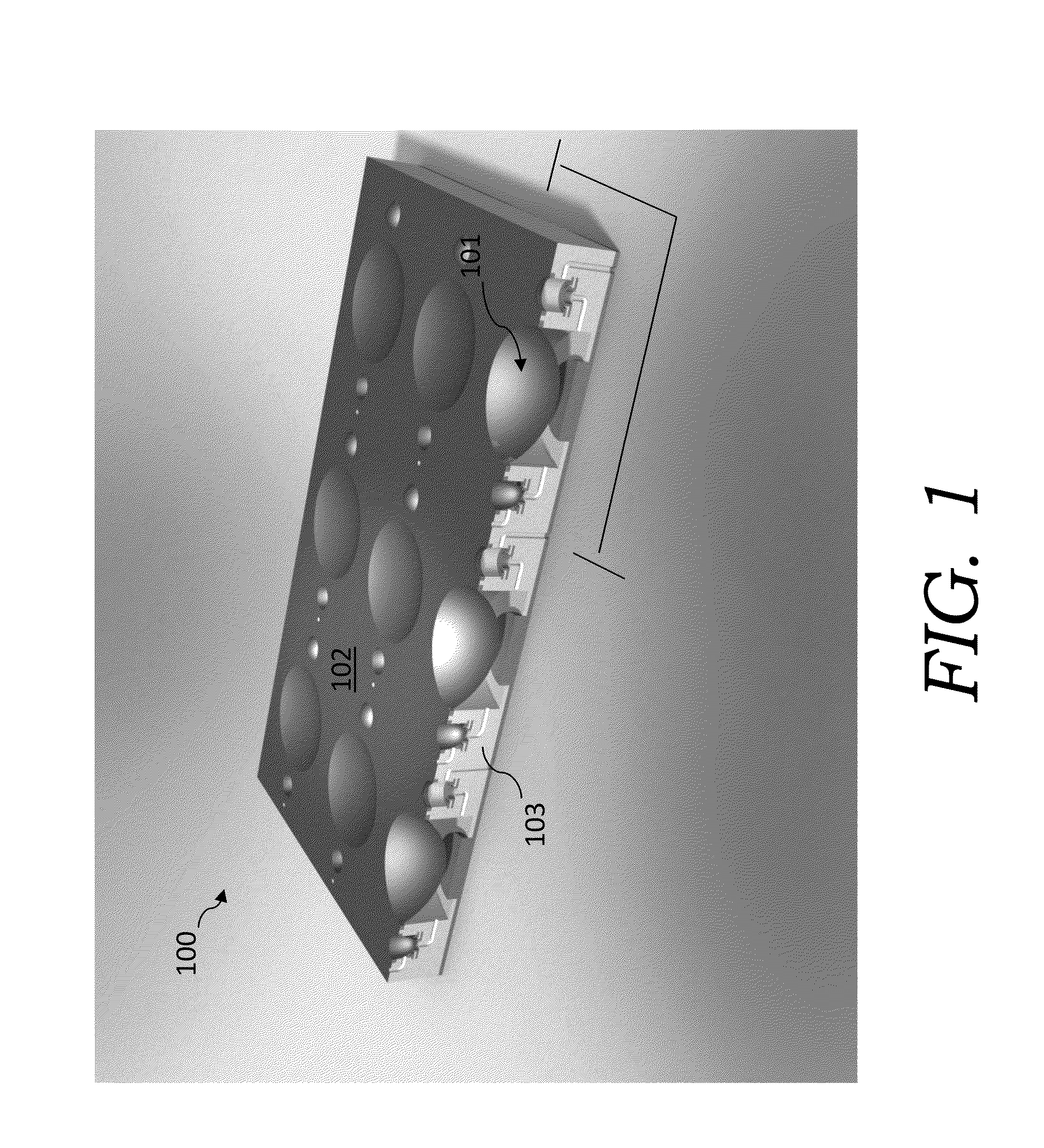

[0107]In an embodiment of the present invention, one or more graphene drums can be utilized in a pump system. FIG. 1 depicts a graphene-drum pump system 100 that has an array of graphene-drum pumps 101 (as illustrated there are nine graphene pumps 101 in FIG. 1). As oriented in FIG. 1, the top layer 102 is graphene. The top layer is mounted on an insulating material 103 (such as silicon dioxide).

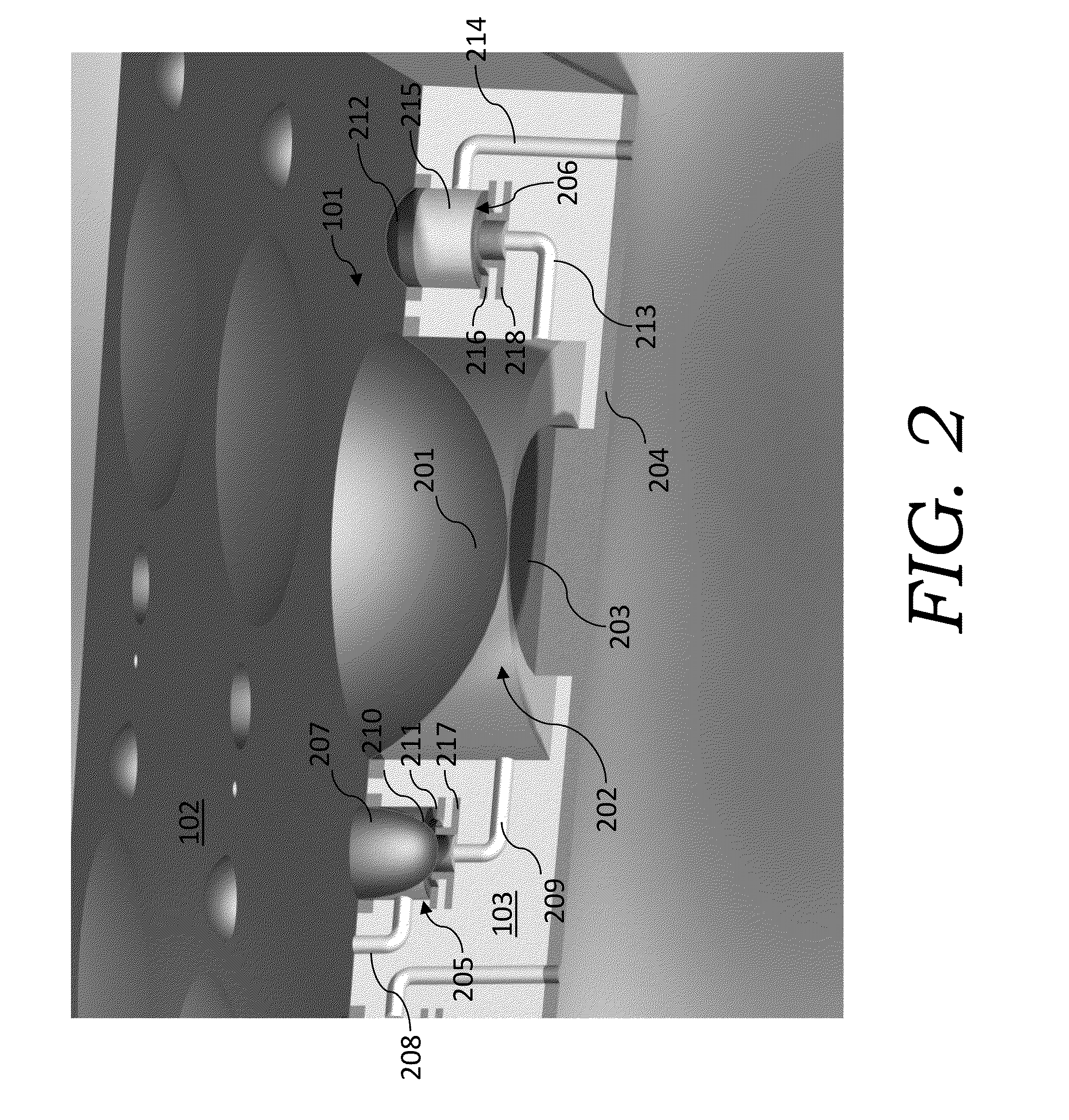

[0108]FIG. 2 depicts a close-up of a graphene-drum pump 101 in the graphene-drum pump system 100 of FIG. 1. Graphene-drum pump 101 utilizes a graphene drum as the main diaphragm (main diaphragm graphene drum 201). The main diaphragm seals a boundary of the cavity 202 of the graphene-drum pump 101. The cavity is also bounded by insulating material 103 and a metallic gate 203 (which is a metal such as tungsten). The metallic gate 203 is operatively connected to a voltage source (not shown), such as by a metallic trace 204. The main diaphragm graphene drum 201 can be designed to operate in a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com