Coating method for liquid crystal alignment film of tft-lcd

a liquid crystal alignment and coating technology, applied in the direction of semiconductor devices, instruments, electrical devices, etc., can solve the problems of large consumable consumption, cumbersome equipment, poor mobility, etc., and achieve the effect of effective control of the precision of the printing of the alignment film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention will become more fully understood by reference to the following detailed description thereof when read in conjunction with the attached drawings.

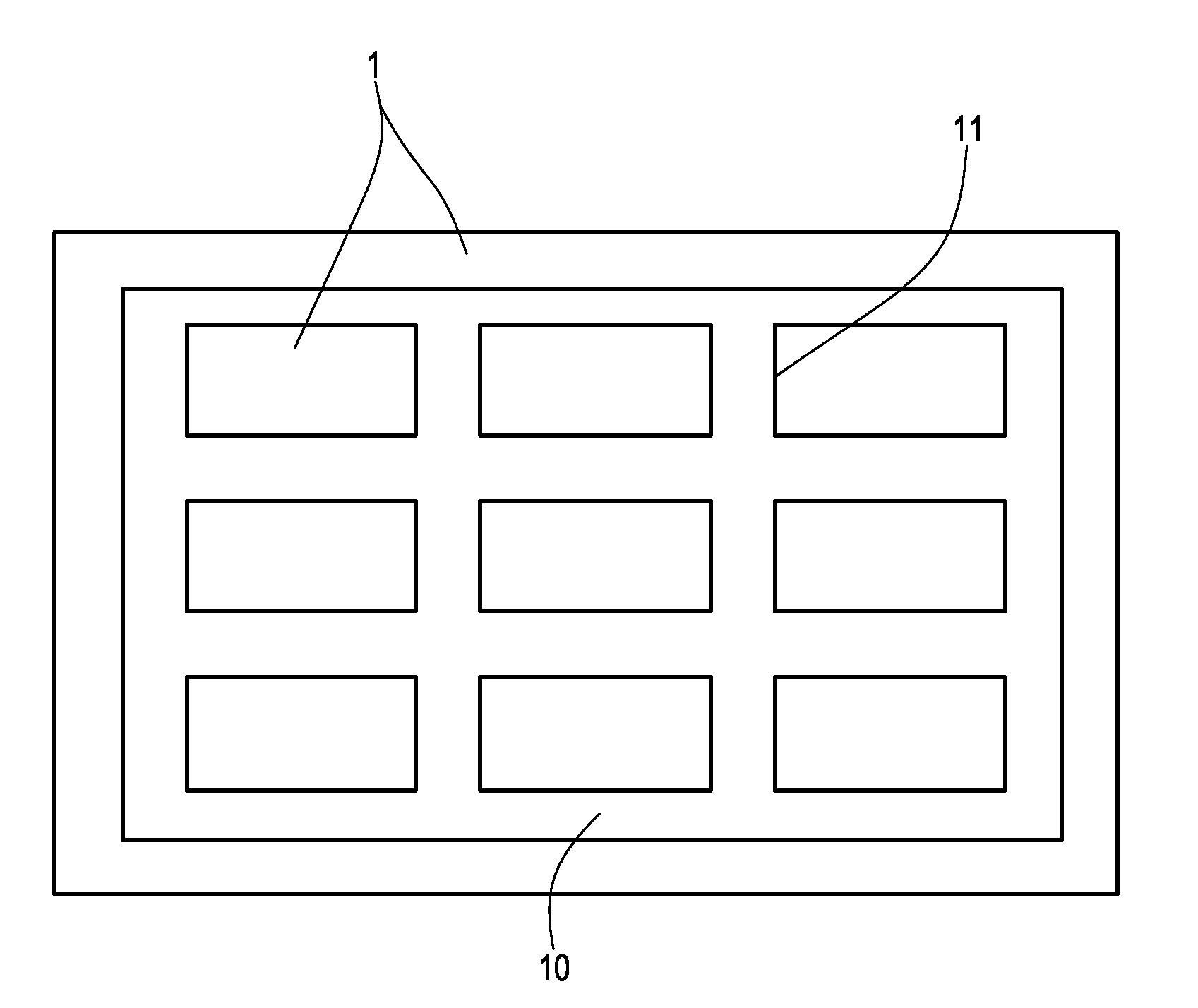

[0027]Referring to FIG. 5, the present invention provides a coating method for liquid crystal alignment film of TFT-LCD, forming a layer of hydrophobic film 10 on a TFT / CF substrate 1 corresponding to a non-display area, the hydrophobic film 10 separates the TFT / CF substrate 1 into a plurality of rectangular opened areas which are separated from each other, each of the rectangular opened areas corresponds to a display area and its outer frame is formed by the hydrophobic film 10; and coating of a liquid of a material of an alignment film along a boundary 11 of the rectangular opened area. Preferably, the material of the alignment film is PI (polyimide).

[0028]In the coating method of the present invention, it further includes: forming a layer of hydrophilic film on the rectangular opened area, the coating of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com