Rear-mounted aerodynamic structures for cargo bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

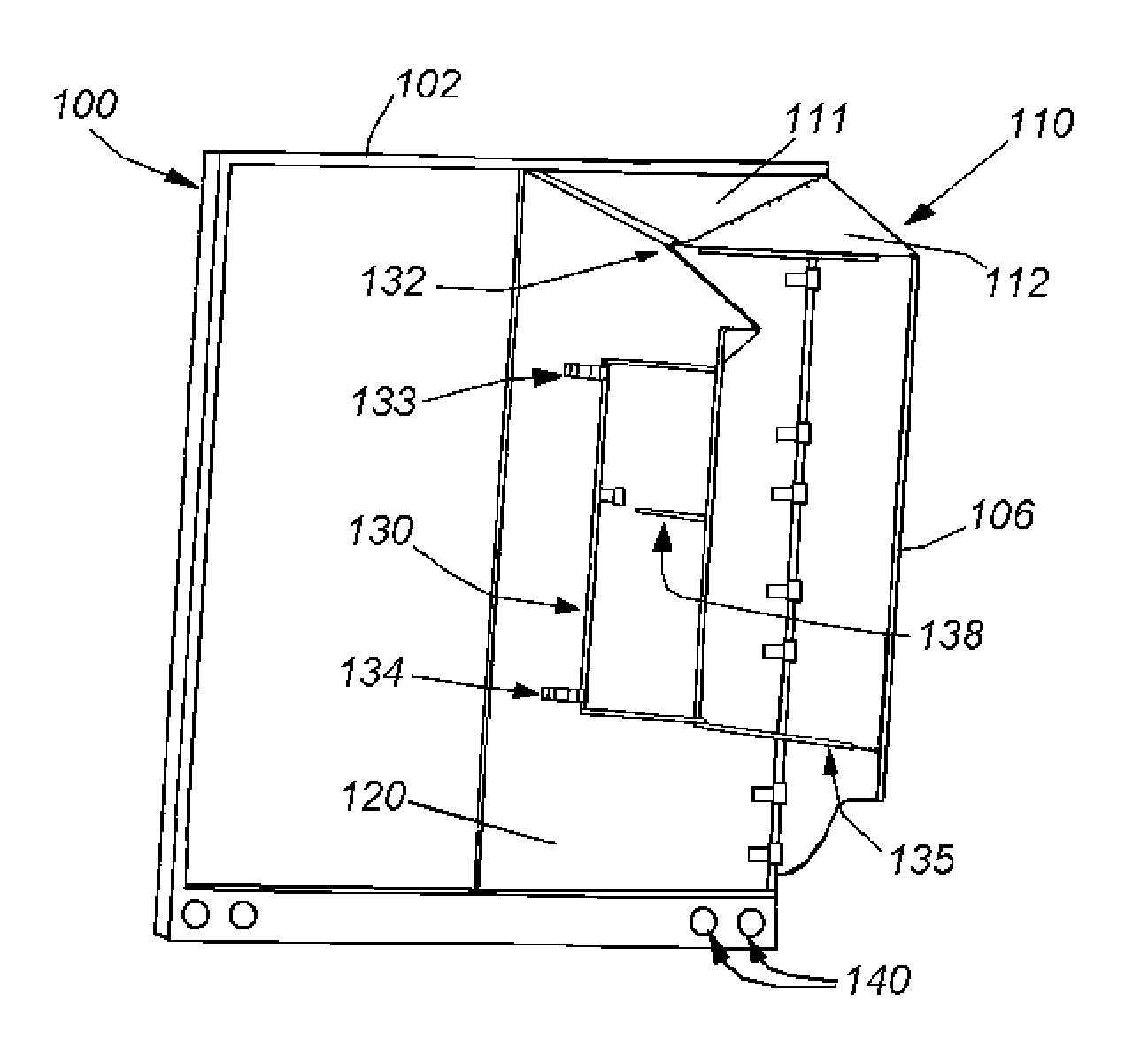

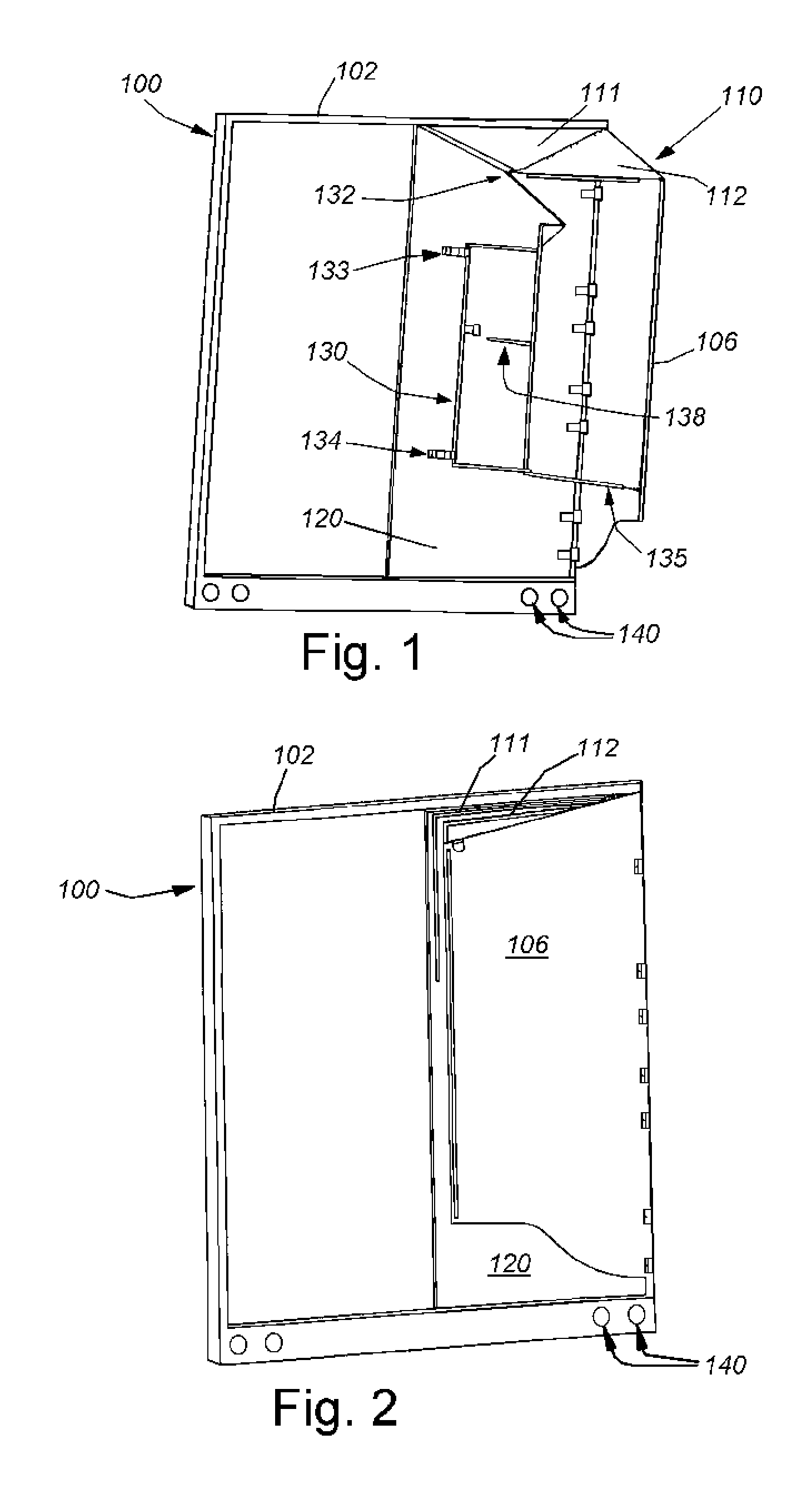

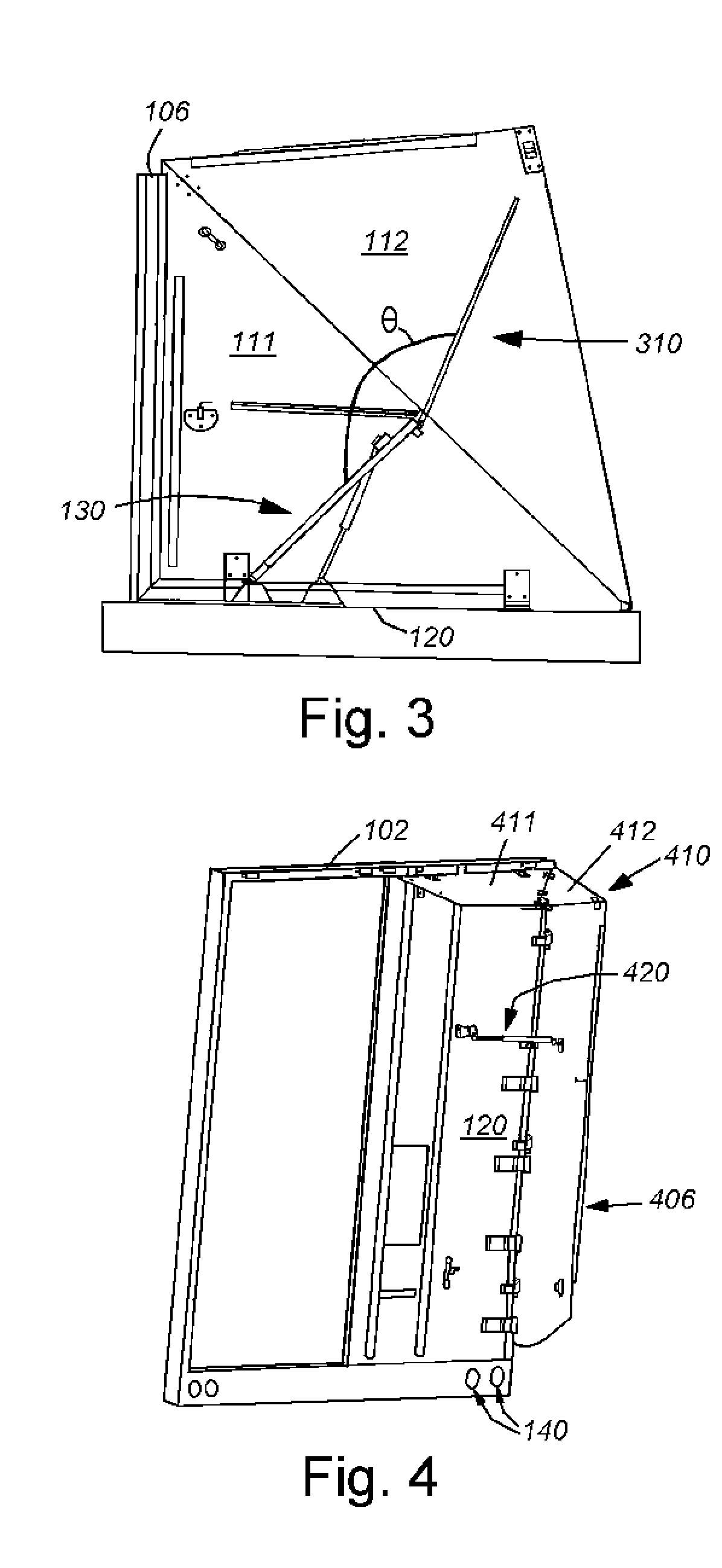

[0082]A rear-mounted aerodynamic structure for securing to a cargo body includes a three- or four-sided structure having a deployed position for assisting in improving aerodynamic efficiency of the cargo body. The cargo body can be the body of a trailer of a tractor-trailer vehicle or trailer towed behind a vehicle such as a truck. It can comprise a trailer body or other cargo body well-known in the art. In an illustrative embodiment, a spoiler “flow keeper” is mounted to a top surface of the rear of the cargo body, as an additional aerodynamic structure or as a standalone spoiler for cargo bodies. The three- or four-sided rear-mounted aerodynamic structure can comprise any of a variety of illustrative embodiments shown and described herein, as well as additional aerodynamic structures as shown and described herein.

[0083]I) Rear-Mounted Aerodynamic Structure Including Upper Panel and Side Panel

[0084]Reference is made to FIG. 1 showing a rear perspective view of a single door-mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com