Centrifugal compressor

a centrifugal compressor and compressor technology, applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of high pressure loss, damage to efficiency, and expensive finishing, and achieve the effect of reducing production expenditure and high pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

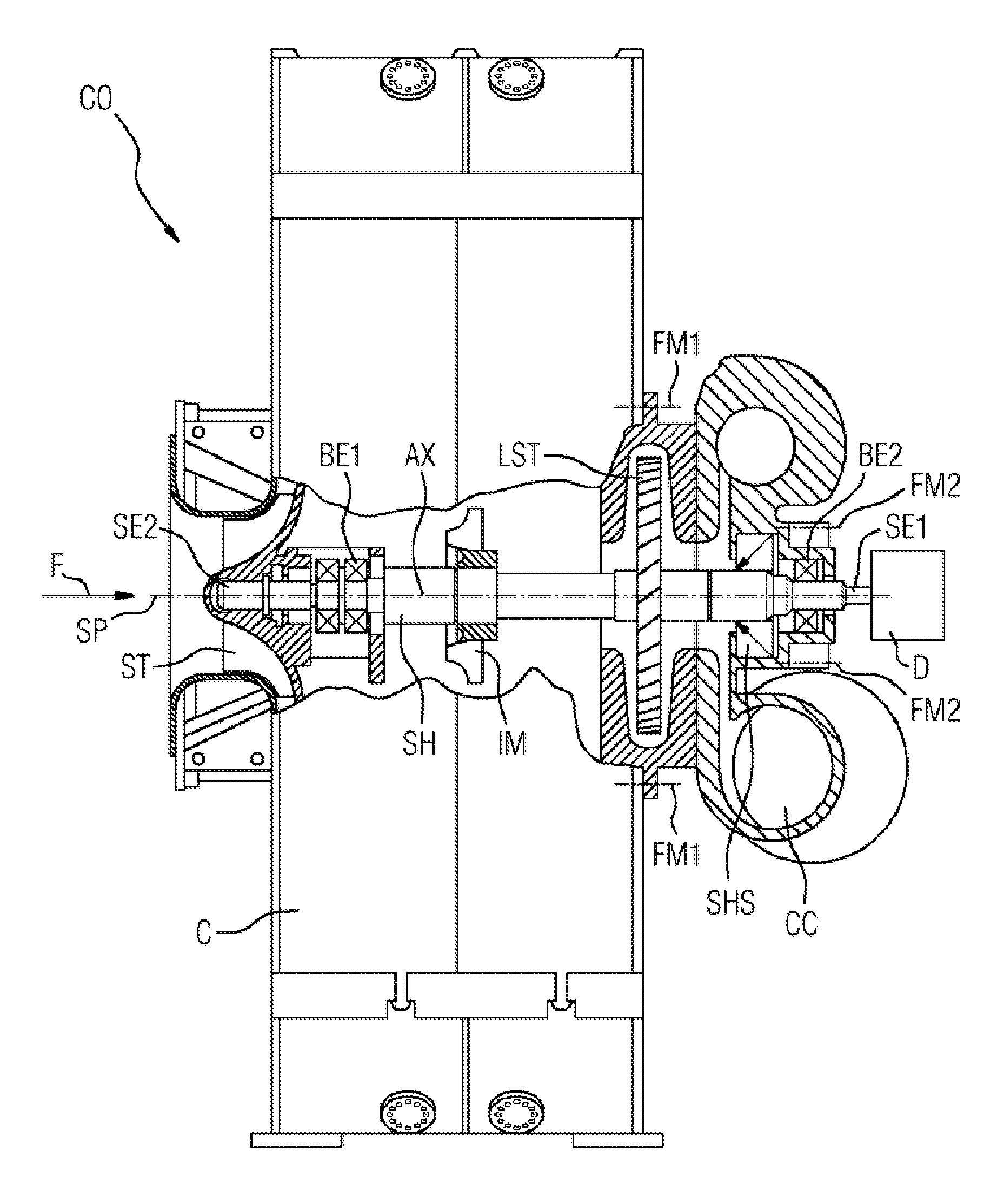

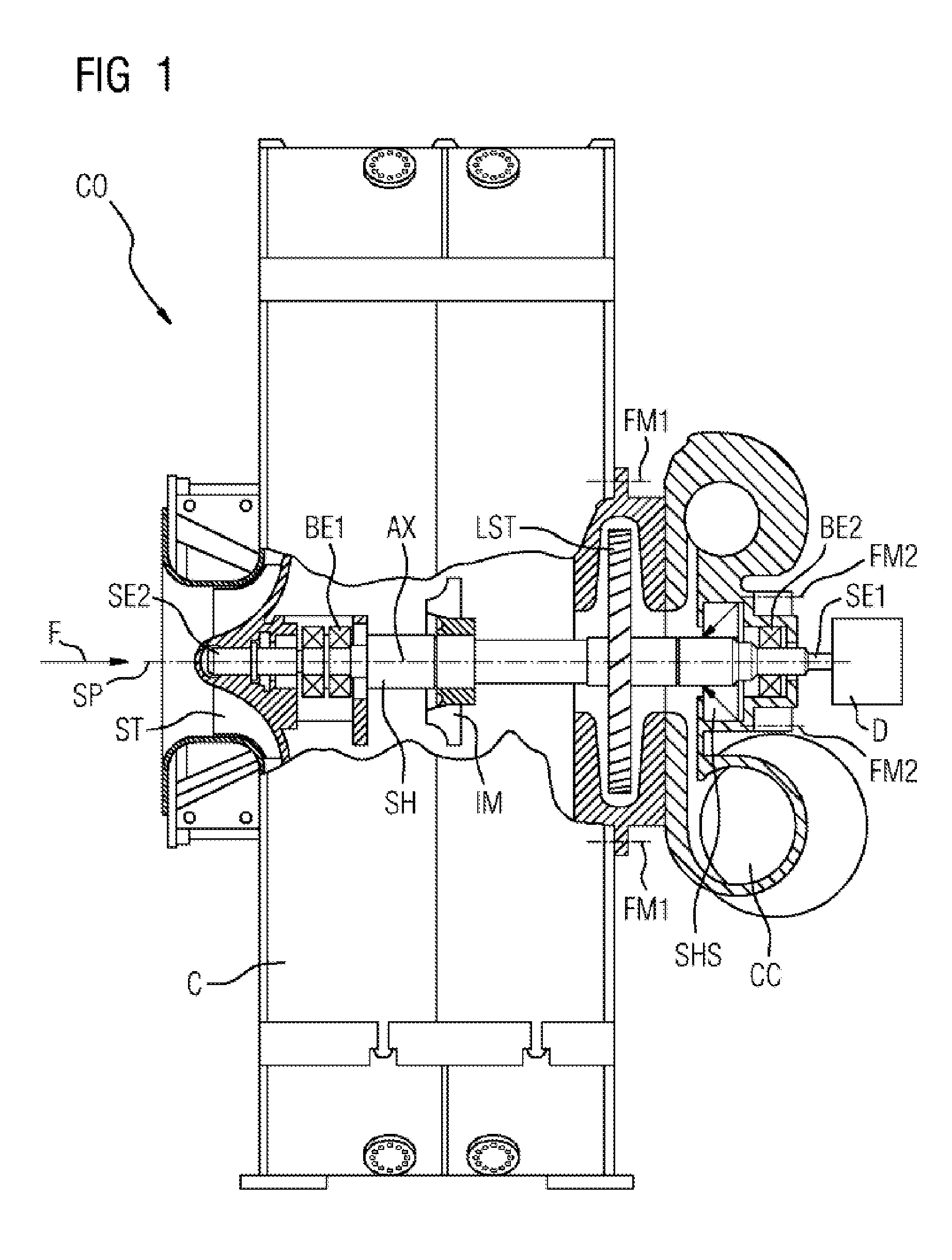

[0016]FIG. 1 shows a schematic longitudinal section through a compressor CO as claimed in the invention. Essential component parts of the compressor CO are a housing C, a shaft SH, the impellers IM—only one of which is shown and supports an overhang stage ST, a collector helix CC which is flanged to the housing C and a drive D which rotates the shaft SH.

[0017]The shaft SH extends along a machine axis AX which is at the same time the axis of rotation of the drive D. A process fluid F is sucked in axially by the compressor CO and enters into an overhang stage ST, continues to be compressed downstream by means of the impellers IM and enters into a last stage LST in order to be collected finally in the collector helix CC for entry into the machine module downstream. The shaft SH is mounted in two radial bearings BE1, BE2. The shaft SH has a first shaft end SE1 and a second shaft end SE2, the first shaft end SE1 being driven by the drive D and the second shaft end SE2 carrying the overha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com