Hoop earring closure construction and method of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

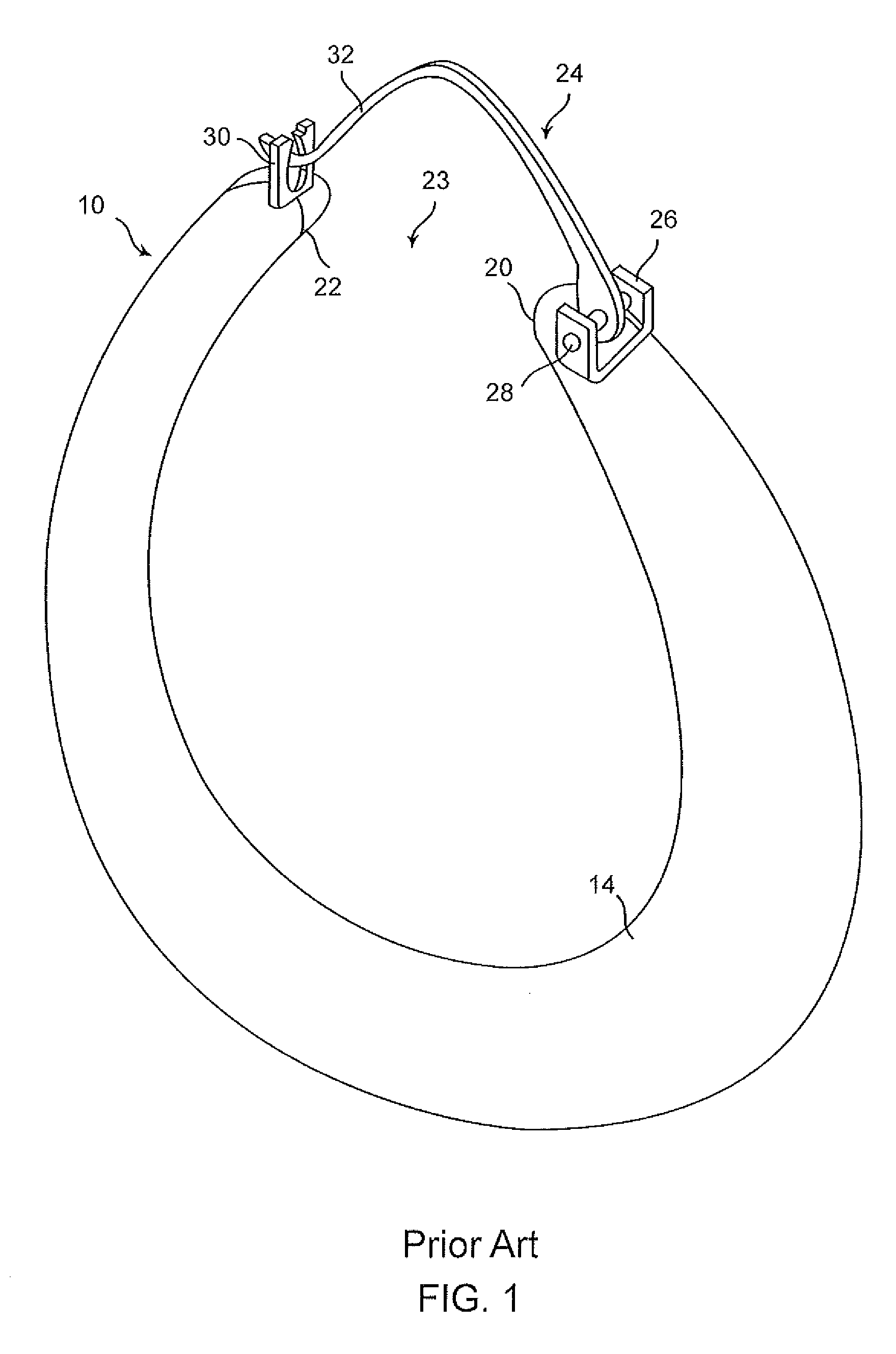

[0032]Referring to the drawings in FIG. 1 a prior art conventional hoop 10 earring is shown, and will be seen to comprise a hoop body 14.

[0033]The earring body typically will be of precious metal or an alloy of precious metal or, in today's climate, of non-precious metal. It is to be mentioned that the earring body can take any suitable form and can be constructed of any appropriate material.

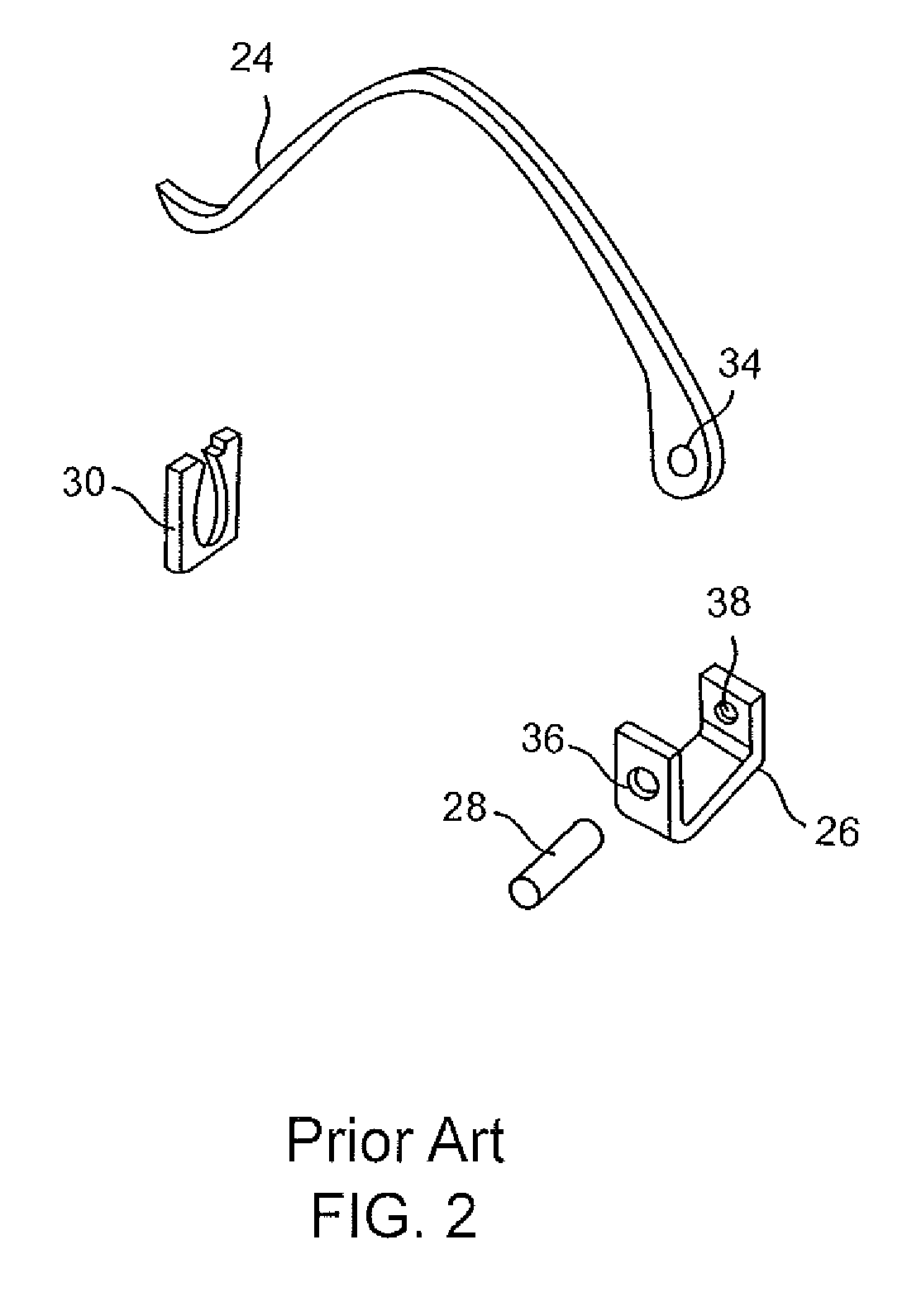

[0034]Because of the shape of the body 14, it defines at the top thereof two ends 20 and 22 between which is a gap 23 bridged by a hinge bar 24 of the earring. The hinge bar 24 is supported for hinging movement at end 20 by being mounted on a plate bracket 26 through which and through the end of the hinge bar passes a hinge pin 28. The hinge bar is conventionally formed of a solid metal.

[0035]A clasp plate 30 is provided on the other end 22 which is of U-shape form, so that the free end 32 of the hinge bar 24 can be snapped into the clasp 30 to hold it in the position shown.

[0036]In the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com